A kind of amphiphilic core-shell porous polymer microsphere and preparation method thereof

A technology of porous polymer and hydrophilic polymer, applied in the field of amphiphilic core-shell porous polymer microspheres and their preparation, can solve the problem of low universality, poor uniformity of microsphere size, lack of functional groups, etc. problems, to achieve the effect of easy control of experimental conditions, controllable pore size, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

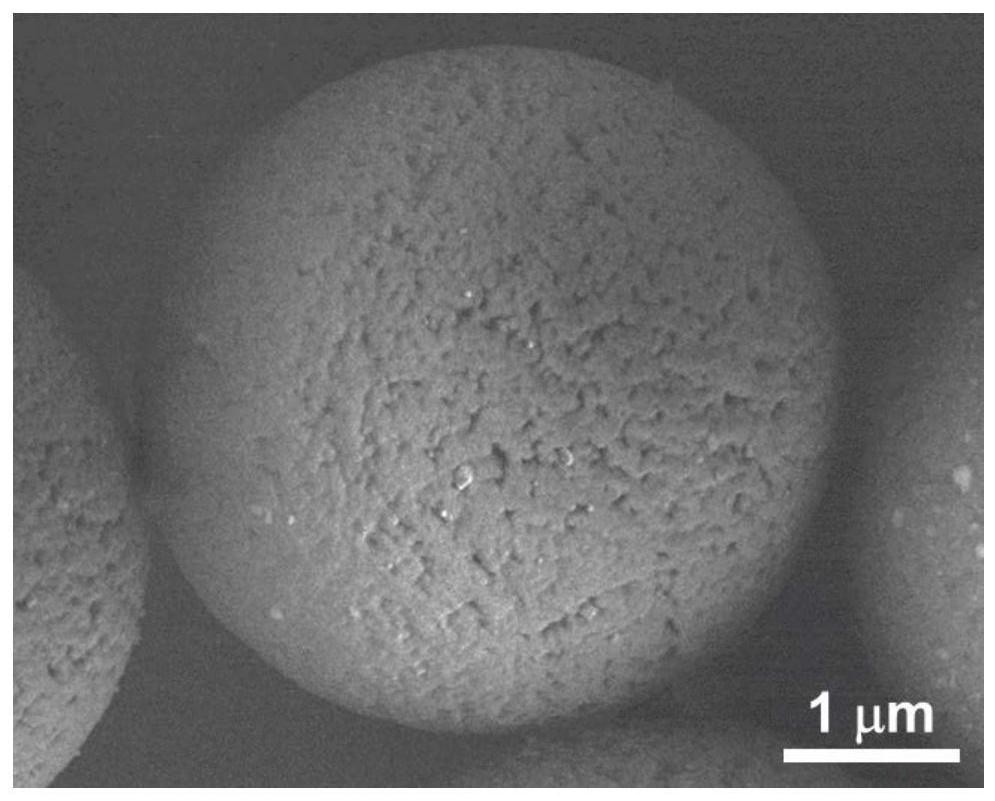

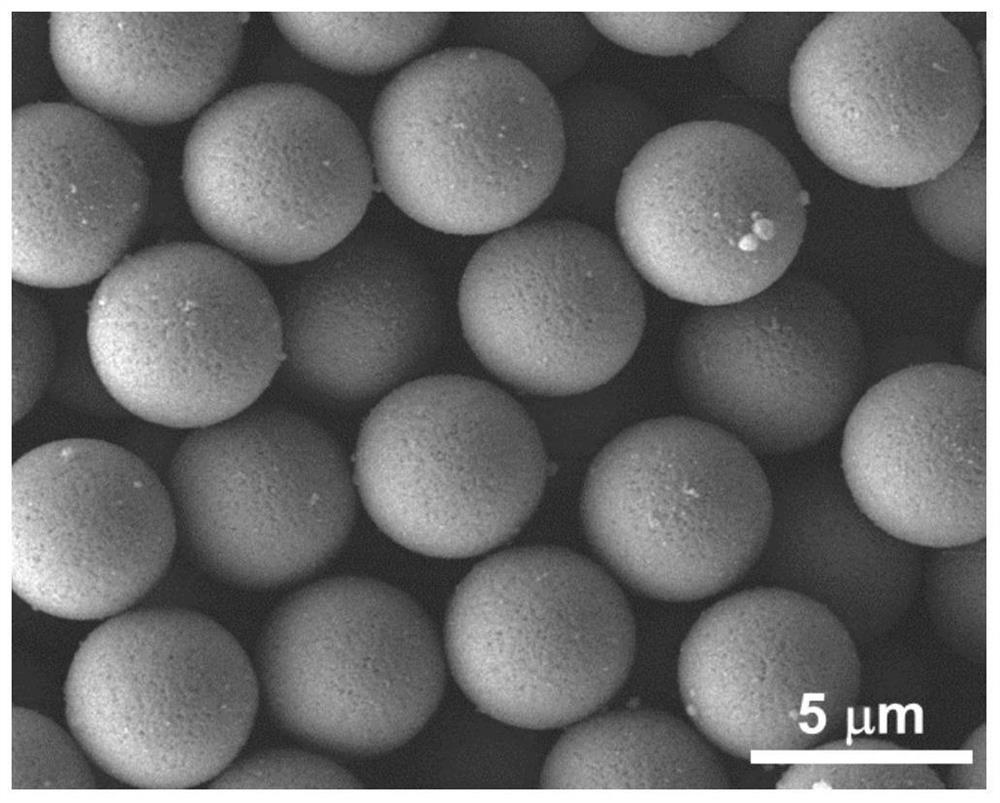

[0038] Embodiment 1 Amphiphilic porous polymer microsphere

[0039] A preparation method of amphiphilic porous polymer microspheres, comprising the following steps:

[0040] a) Add the emulsified emulsion containing 0.1mL dodecane chloride to 20mL aqueous solution of polystyrene microspheres with a concentration of 10mg / mL, and stir at 40°C for 24h, wherein the diameter of the polystyrene microspheres is 2μm ;

[0041] b) Add 20mmol of styrene, 7mmol of divinylbenzene, 0.2mmol of azobisisobutyronitrile initiator, and 5mmol of acrylamide into 15mL of sodium dodecylsulfonate aqueous solution with a concentration of 0.003g / mL, and emulsify for 1min;

[0042] c) adding the hydrophilic / hydrophobic monomer emulsion obtained in step b) to the solution obtained in step a), and stirring at 40°C for 6h;

[0043] d) pass the emulsion obtained in step c) into N 2 10min, stirring and reacting for 24h at a polymerization temperature of 70°C;

[0044] e) The solution obtained from the r...

Embodiment 2

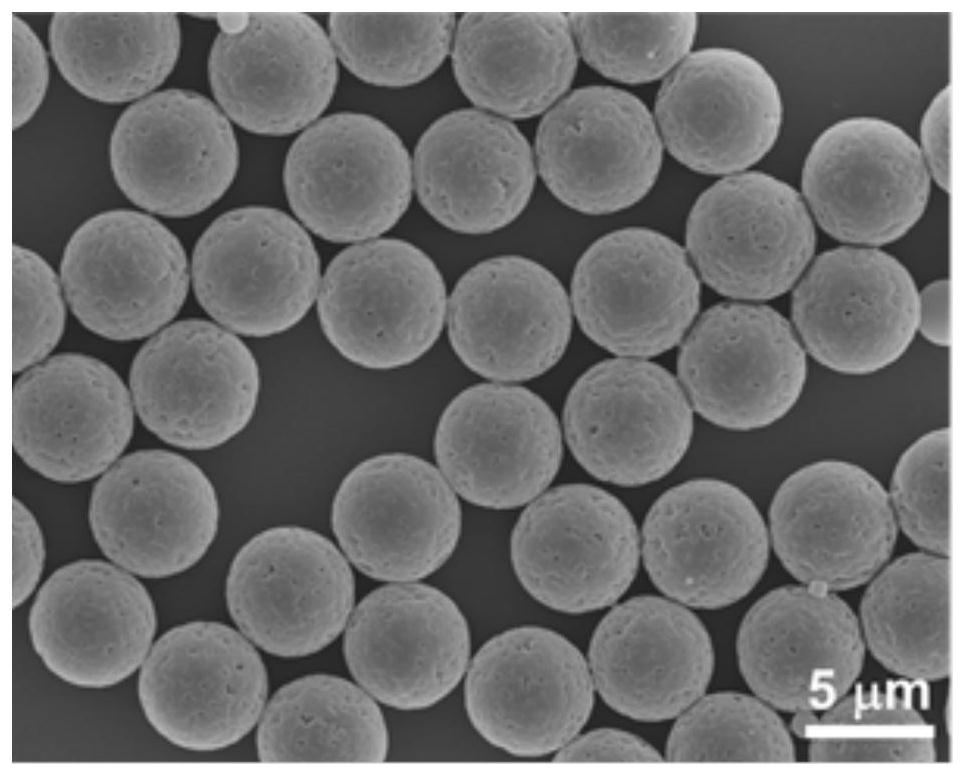

[0046] Embodiment 2 Amphiphilic porous polymer microspheres

[0047]A preparation method of amphiphilic porous polymer microspheres, comprising the following steps:

[0048] a) Add the emulsified emulsion containing 0.1 mL of toluene to 20 mL of an aqueous solution of polystyrene microspheres with a concentration of 10 mg / mL, and stir at 30° C. for 12 h, wherein the diameter of the polystyrene microspheres is 0.8 μm;

[0049] b) 30mmol α-methylstyrene, 20mmol divinylbenzene, 0.3mmol azobisisoheptanonitrile initiator, and 8mmol acrylic acid are added to 15mL concentration of 0.002g / mL sodium dodecylbenzenesulfonate aqueous solution, Emulsify for 3 minutes;

[0050] c) adding the hydrophilic / hydrophobic monomer emulsion obtained in step b) to the solution obtained in step a), and stirring at 30° C. for 10 h;

[0051] d) pass the emulsion obtained in step c) into N 2 20min, stirring and reacting for 12h at a polymerization temperature of 65°C;

[0052] e) The solution obtain...

Embodiment 3

[0054] Embodiment 3 Amphiphilic porous polymer microspheres

[0055] A preparation method of amphiphilic porous polymer microspheres, comprising the following steps:

[0056] a) Add the emulsified emulsion containing 0.02mL bromododecane to 5mL aqueous solution of polystyrene microspheres with a concentration of 1mg / mL, and stir at 20°C for 36h, wherein the diameter of polystyrene microspheres is 1.2μm ;

[0057] b) 10mmol o-chlorostyrene, 7mmol divinylbenzene, 1mmol azobicyclohexylcarbonitrile initiator, and 50mmol acrylamide are added to 5mL concentration of 0.005g / mL sodium dodecylsulfonate aqueous solution, Emulsify for 1min;

[0058] c) adding the hydrophilic / hydrophobic monomer emulsion obtained in step b) to the solution obtained in step a), and stirring at 20° C. for 5 h;

[0059] d) pass the emulsion obtained in step c) into N 2 10min, stirring and reacting for 8h at a polymerization reaction temperature of 80°C;

[0060] e) The solution obtained from the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com