Preparation method and application of MnO2 nanowire

A nanowire and reaction technology, which is applied in the field of MnO2 nanowire preparation, can solve the problems of high reaction temperature, long synthesis time, and restrictions on the popularization and application of materials, and achieve the effects of easy reaction conditions, simple methods, and reduced synthesis costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a kind of MnO 2 A method for preparing nanowires, comprising the steps of:

[0032] Preparation of polypyrrole:

[0033] Dissolve 0.294 g of methyl orange (MO) in 180 mL of FeCl 3 6H 2 O (1.44g) solution, then stirred and ultrasonically dispersed. Then, 330 μL of pyrrole monomer was added to the above suspension solution, and magnetically stirred at room temperature for 24 h, and a black precipitate was formed in the reaction. The black precipitate was washed with deionized water and absolute ethanol several times until the filtrate became colorless and neutral, and finally dried in a vacuum oven at 50° C. for 12 hours to obtain PPy (polypyrrole).

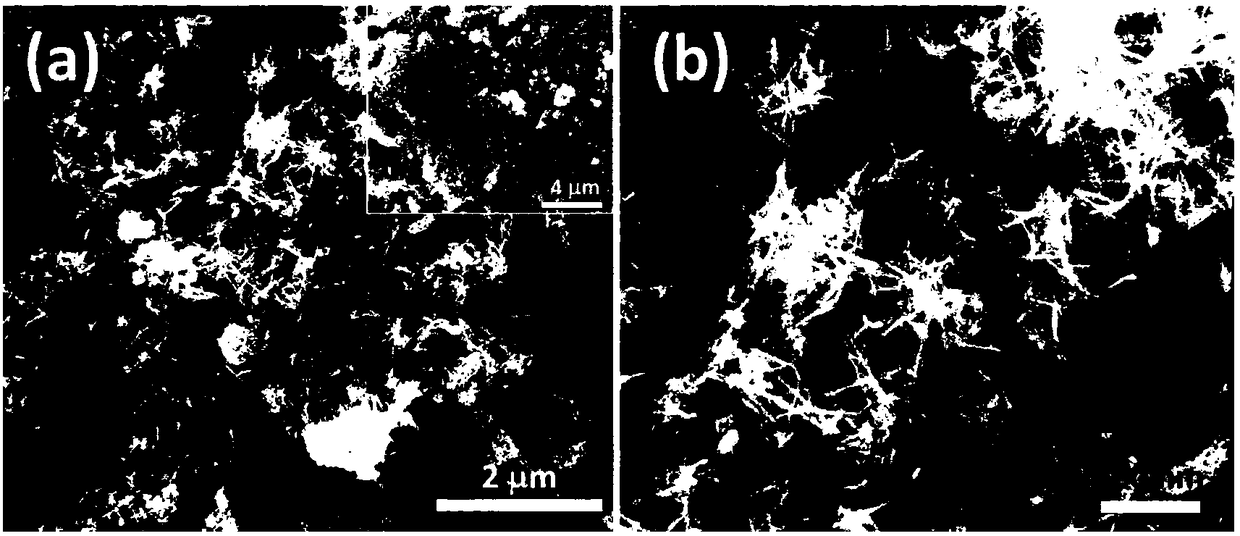

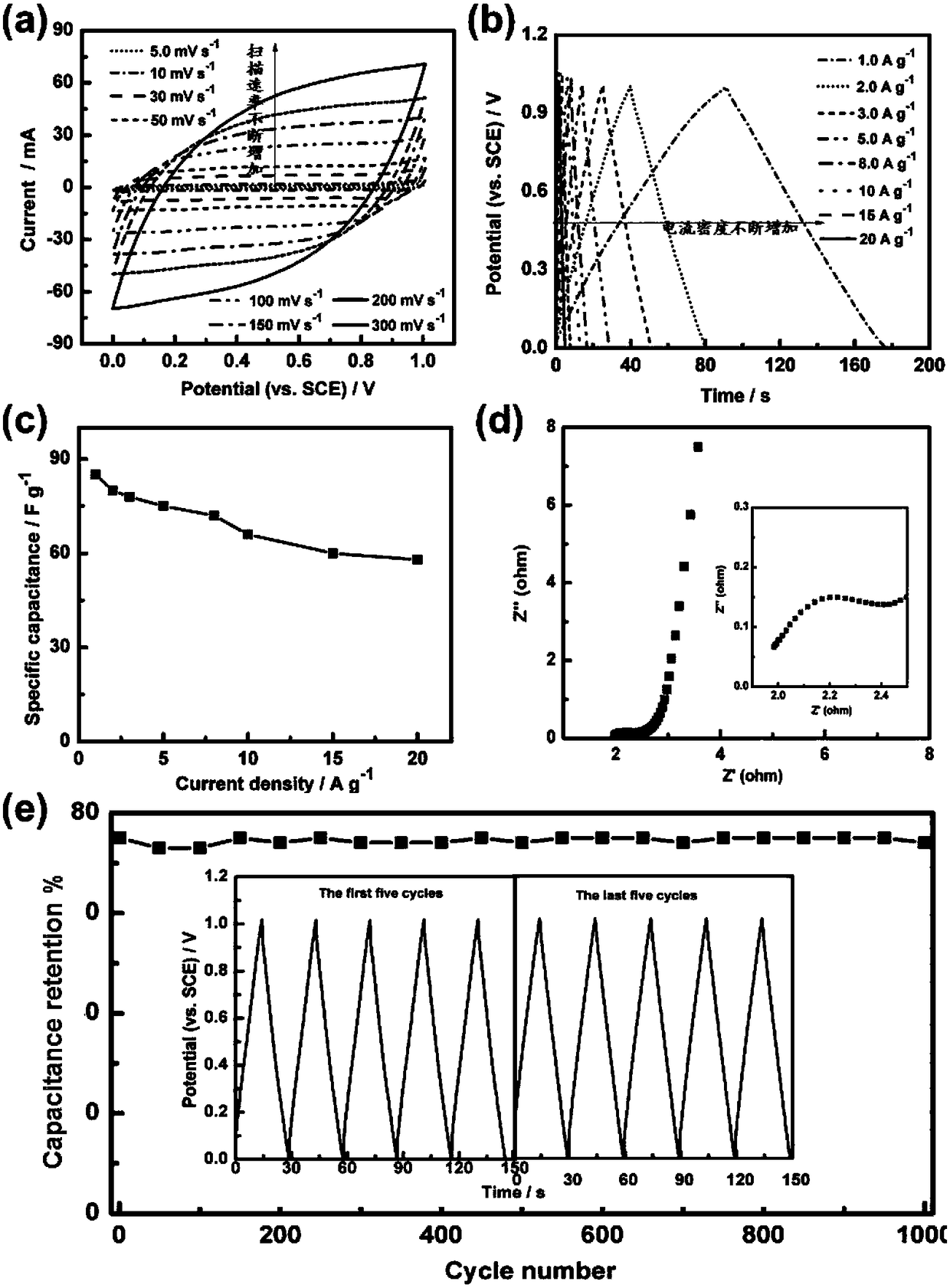

[0034] MnO 2 Preparation of nanowires:

[0035] 1) Add 0.265mlH 2 SO 4 Add to 30mlKMnO 4 (0.79g) solution, stirred evenly by magnetic force. Then, the above mixed solution was added to an aqueous solution (20 mL) in which 120 mg of polypyrrole powder was dissolved to form a pre-reaction s...

Embodiment 2

[0040] This embodiment relates to a kind of MnO 2 A method for preparing nanowires, comprising the steps of:

[0041] 1) Add 0.265mlH 2 SO 4 Add to 30mlKMnO 4 (0.79g) solution, stirred evenly by magnetic force. Then, the above mixed solution was added to an aqueous solution (20 mL) in which 80 mg of polypyrrole powder was dissolved to form a pre-reaction solution;

[0042] 2) Place the pre-reaction solution in a water bath at 80°C. In this step, the reaction time was controlled at 60 minutes. The synthesized sample was washed with deionized water and absolute ethanol, and finally the sample was dried in a vacuum oven at 60°C for 12 hours to obtain MnO 2 Nanowires.

Embodiment 3

[0044] This embodiment relates to a kind of MnO 2 A method for preparing nanowires, comprising the steps of:

[0045] 1) Add 0.265mlH 2 SO 4 Add to 30mlKMnO 4 (0.79g) solution, stir evenly by magnetic force. Then, the above mixed solution was added to an aqueous solution (20 mL) in which 140 mg of polypyrrole powder was dissolved to form a pre-reaction solution;

[0046] 2) Place the pre-reaction solution in a water bath at 85°C. In this step, the reaction time was controlled at 60 minutes. The synthesized sample was washed with deionized water and absolute ethanol, and finally the sample was dried in a vacuum oven at 60°C for 12 hours to obtain MnO 2 Nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com