A charge-coupled device based on two-dimensional material thin film/insulating layer/semiconductor structure

A charge-coupled device and material thin film technology, applied in the field of image sensors, can solve the problems of difficulty in controlling the CCD yield rate, data cannot be transmitted normally, and slow response speed, so as to improve the overall response speed, improve quantum efficiency, and reduce dark current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

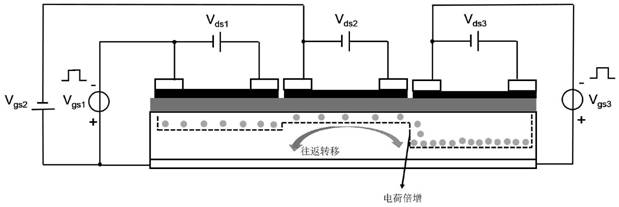

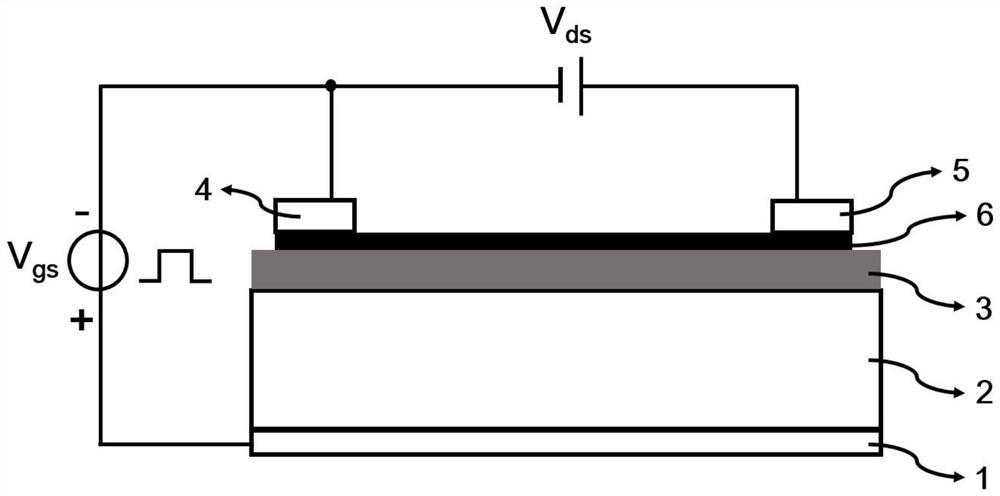

[0035] Depend on figure 1 As shown, a charge-coupled device based on a two-dimensional material thin film / insulating layer / semiconductor structure in this embodiment includes several pixels forming an array, and the pixels sequentially include a gate 1, a semiconductor substrate 2, and an insulating layer from bottom to top. 3. Graphene film 6, source 4 and drain 5; graphene film 6 covers the upper surface of insulating layer 3; source 4 and drain 5 are horizontally arranged on the upper surface of graphene film 6, and graphene film 6 has photoelectric response and field effect at the same time.

[0036] Among them, the material for making the gate 1 is gallium indium alloy, the thickness of the semiconductor substrate 2 is 300-500 μm, the resistivity is 1-10 Ω·cm, the thickness of the insulating layer 3 is 10-100 nm, the source 4 and the drain 5 The material used is chromium / gold alloy, and the size of the graphene film 6 is 100 μm×100 μm.

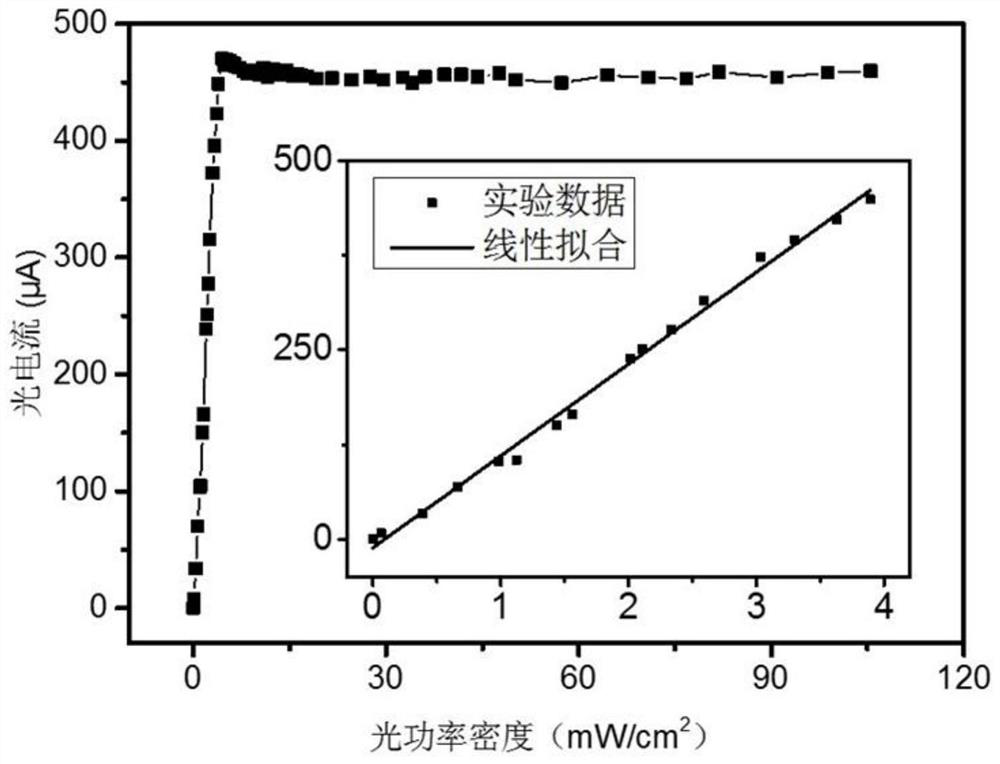

[0037] A pulsed gate voltage is ...

Embodiment 2

[0047] Depend on figure 1 As shown, a charge-coupled device based on a two-dimensional material thin film / insulating layer / semiconductor structure in this embodiment includes several pixels forming an array, and the pixels sequentially include a gate 1, a semiconductor substrate 2, and an insulating layer from bottom to top. 3. Black phosphorus film 6, source electrode 4 and drain electrode 5; black phosphorus film 6 covers the upper surface of insulating layer 3; source electrode 4 and drain electrode 5 are horizontally arranged on the upper surface of black phosphorus film 6, and black phosphorus film 6 has photoelectric response and field effect at the same time.

[0048] Among them, the material for making the gate 1 is gallium indium alloy, the thickness of the semiconductor substrate 2 is 300-500 μm, the resistivity is 1-10 Ω·cm, the thickness of the insulating layer 3 is 10-100 nm, the source 4 and the drain 5 The material used is chromium / gold alloy, and the size of t...

Embodiment 3

[0054] Depend on figure 1 As shown, a charge-coupled device based on a two-dimensional material thin film / insulating layer / semiconductor structure in this embodiment includes several pixels forming an array, and the pixels sequentially include a gate 1 and a narrow bandgap semiconductor substrate 2 from bottom to top. , an insulating layer 3, a molybdenum disulfide film 6, a source 4 and a drain 5; the molybdenum disulfide film 6 covers the upper surface of the insulating layer 3; the source 4 and the drain 5 are horizontally arranged on the molybdenum disulfide film 6 On the upper surface, the molybdenum disulfide thin film 6 has photoelectric response and field effect at the same time.

[0055] Among them, the material for making the gate 1 is gallium-indium alloy, and the narrow-bandgap semiconductor 2 is made of germanium Ge, indium antimonide InSb, indium gallium arsenide InGaAs or III-V compound semiconductor, the thickness of which is 300-500 μm, and the resistivity is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com