A kind of preparation method and application of titanium dioxide coated ferric oxide composite material

A technology of ferric oxide and titanium dioxide, which is applied in the field of new energy materials for lithium-ion batteries, can solve problems such as poor rate performance, collapse of material structure, slow electron transmission, etc., to facilitate large-scale production, low equipment requirements, and preparation conditions Simple and gentle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further elaborate the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the preferred embodiments, a description of the preparation method and application of a titanium dioxide-coated ferric oxide composite material proposed according to the present invention Specific embodiments, methods, steps, features and effects thereof are described in detail as follows:

[0025] Implementation column 1:

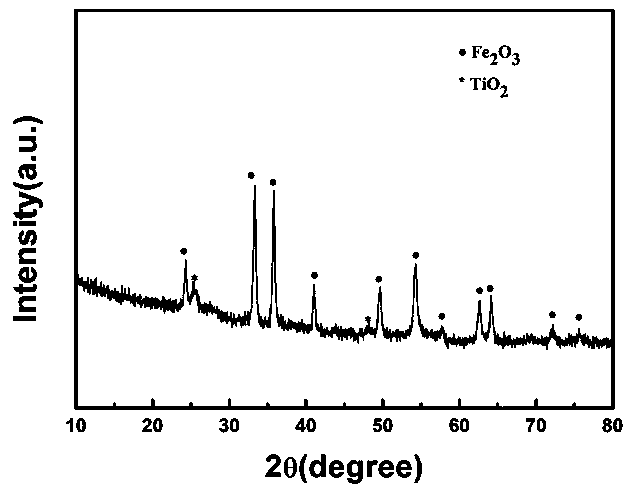

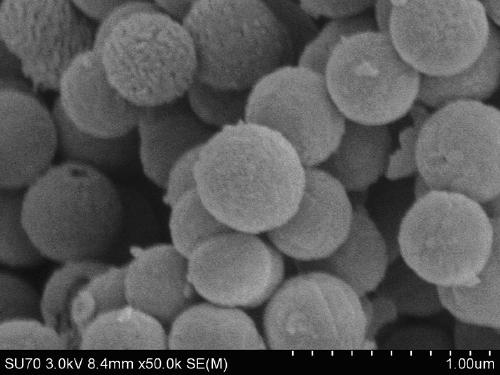

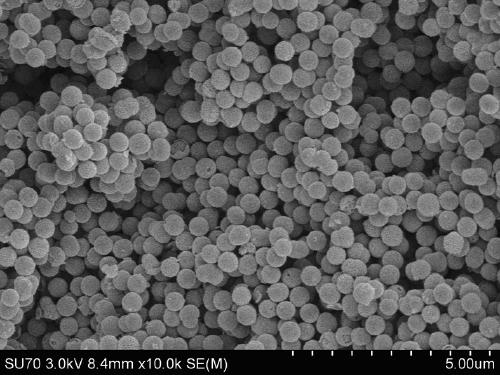

[0026] Weigh 0.32g ferric nitrate nonahydrate and dissolve it in 5ml glycerol and 35ml dehydrated ethanol, stir to form a molar concentration of iron ions that is 0.02 mol / orange solution; then transfer the mixed solution into a 50 ml hydrothermal kettle, React at 170°C for 24 hours, then cool naturally, wash, centrifuge, and dry at 60°C to obtain ferric oxide microspheres; weigh 0.075g of ferric oxide microspheres and dissolve them in 100ml of absolute ethanol, then add a concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com