3-d printing of a ceramic component

A technology for components, ceramics, applied in the direction of ceramic molding machines, ceramic layered products, additive processing of mixtures of solid and liquid materials, etc., which can solve problems such as lack of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The wrought hard coal tar pitch coke was ground and after grinding and sieving had a particle size distribution of d10 = 130 μm, d50 = 230 μm and d90 = 390 μm and a shape factor of 0.69. A liquid sulfuric acid activator for phenolic resin was first added at 1% by weight based on the total weight of coke and activator to the coke, which was then machined through a 3D printing powder bed. In this process, a doctor blade device deposits a thin layer of coke powder (about 0.3mm in height) on a flat powder bed, and a type of inkjet printing device deposits an alcoholic solution of phenolic resin in accordance with the desired part geometry. Print on the coke bed. The print table is then lowered to an extent equal to the layer thickness, the scorched layer is reapplied, and the phenolic resin is partially printed on top of it again. Using the described iterative procedure, rectangular test specimens with dimensions 168 mm (length) x 22 mm (width) x 22 mm (height) were constr...

Embodiment 2

[0067] To unground wrought acetylene coke with a particle size distribution of d10=117 μm, d50=190 μm and d90=285 μm and a shape factor of 0.82 was added 0.35% by weight of the liquid activator of Example 1, followed by The coke is processed to form a green body.

[0068] The green body has a resin proportion of 3.0% by weight. The density of the green body is 0.98g / cm 3 , and thus significantly higher than the ground hard coal tar pitch coke from Example 1. Furthermore, the green body has a higher strength than the green body from Example 1, making it easier to handle. Thus, supplementary densification of the green body can be dispensed with, thereby reducing production costs.

[0069] The green body was placed directly (without prior separate carbonization) in a siliconization furnace and siliconized as in Example 1. Thus, the binder is carbonized and siliconized in one step.

[0070] analyze

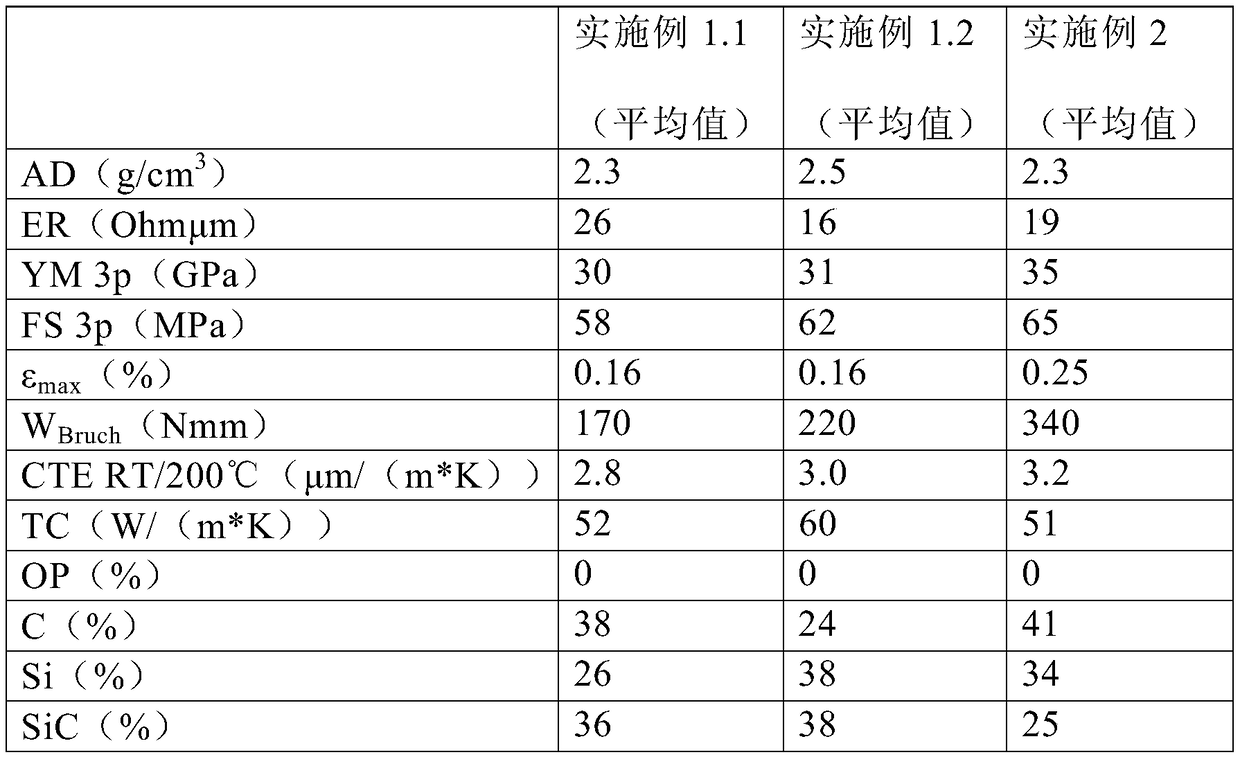

[0071] The table below shows many of the physical and chemical properties...

Embodiment 11

[0082] Example 1.1: Hard coal tar pitch coke, the green body is additionally impregnated with phenolic resin, carbonized and silicified at 900°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com