Polyamide 5X fiber and preparation method thereof

A technology of polyamide and fiber, applied in the field of polyamide 5X fiber and its preparation, can solve the problems of small production capacity and low spinning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

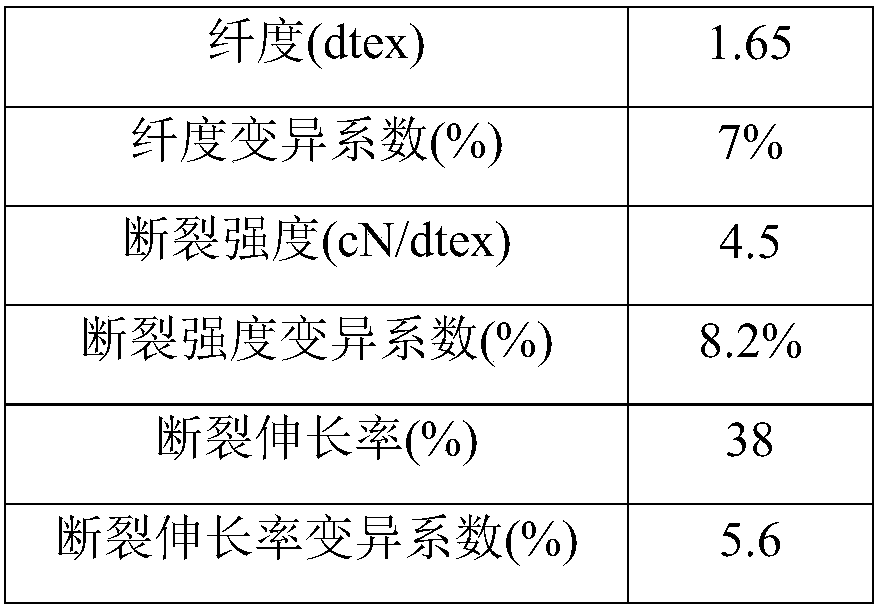

Embodiment 1

[0085] (1) Under nitrogen conditions, mix 1,5-pentanediamine, adipic acid and water uniformly, and mix them uniformly in a reactor to obtain a polyamide 56 salt solution; wherein 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05): 1, and the concentration of the salt solution of polyamide is 50% (the percentage is the mass percent of the salt solution of polyamide); take a small amount of salt solution of polyamide and dilute it to 10%, and measure its The pH value under 25 ℃ is 7.8; The salt solution of polyamide, plasticizer (phthalate plasticizer, 1%), antioxidant (antioxidant 1010, 50ppm), nucleating agent ( Montmorillonite, 100ppm) were mixed uniformly to obtain a mixed solution; the mixed solution was concentrated to a concentration of 85% under the conditions of a pressure of 0.38 MPa and a temperature of 150° C. (the percentage is the mass percent of the polyamide salt solution);

[0086] (2) Heating the system, gradually increasing the pressure to 1.7MPa, ...

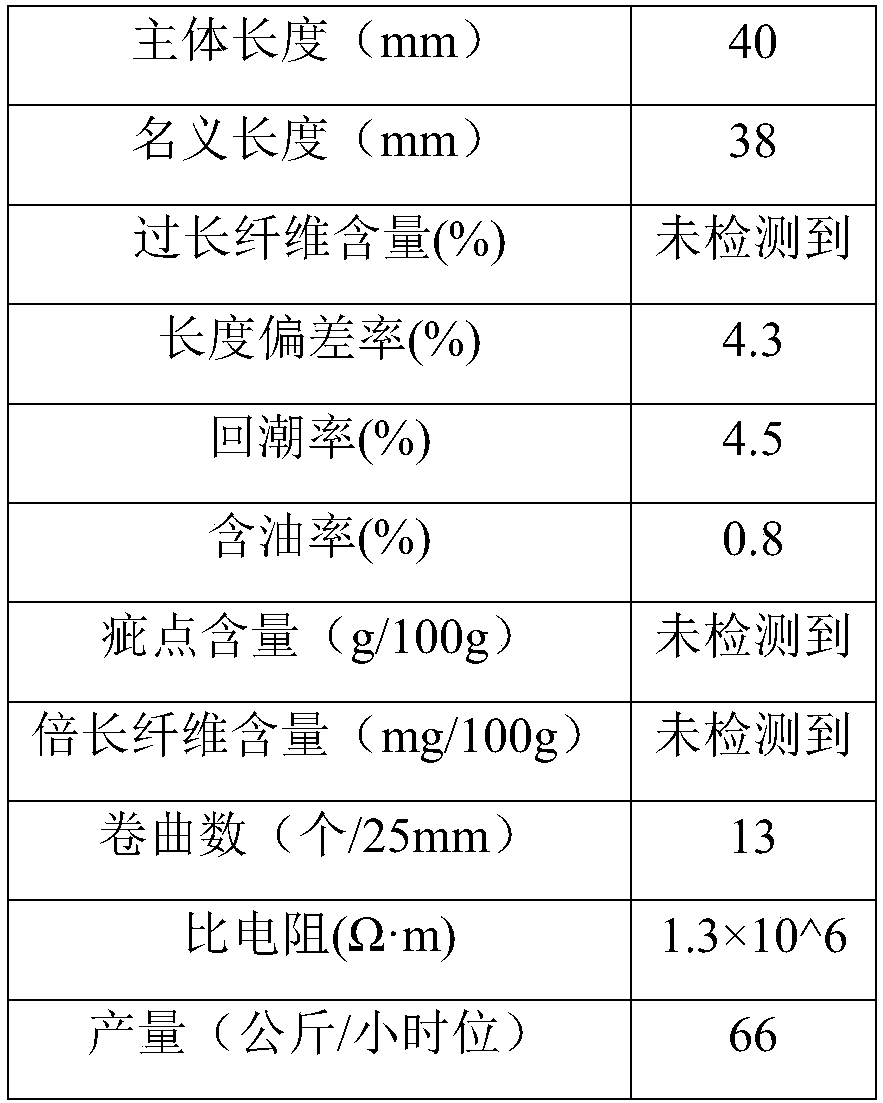

Embodiment 2

[0093] (1) Under nitrogen conditions, mix 1,5-pentanediamine, adipic acid and water uniformly, and mix them uniformly in a reactor to obtain a polyamide 56 salt solution; wherein 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05): 1, and the concentration of the salt solution of polyamide is 60% (the percentage is the mass percent of the salt solution of polyamide); take a small amount of salt solution of polyamide and dilute it to 10%, and measure its The pH value at 25°C is 7.5; the salt solution of polyamide 56 is concentrated to a concentration of 80% under the conditions of a pressure of 0.4MPa and a temperature of 155°C (the percentage is the mass percentage of the salt solution of polyamide), and then mixed with plasticizer Agent (phthalate plasticizer, 1.2%), antioxidant (antioxidant 1076, 80ppm), nucleating agent (talcum powder, 50ppm) mix homogeneously;

[0094] (2) Heating the system, gradually increasing the pressure to 1.7MPa, exhausting, and maintaini...

Embodiment 3

[0100] (1) Under nitrogen conditions, mix 1,5-pentanediamine, adipic acid and water uniformly, and mix them uniformly in a reactor to obtain a polyamide 56 salt solution; wherein 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05): 1, and the concentration of the salt solution of polyamide is 70% (the percentage is the mass percent of the salt solution of polyamide); take a small amount of salt solution of polyamide and dilute it to 10%, and measure its The pH value at 25°C is 8.0; the salt solution of polyamide 56 is concentrated to a concentration of 83% (the percentage is the mass percentage of the salt solution of polyamide) under the conditions of a pressure of 0.45MPa and a temperature of 160°C, and then mixed with plasticizer Agent (paraffin, 0.8%), antioxidant (antioxidant 164, 60ppm), nucleating agent (magnesium hydroxide, 60ppm) mix homogeneously;

[0101] (2) Heating the system, gradually increasing the pressure to 1.65MPa, exhausting, maintaining the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com