Composite probiotic feed additive for pigs and preparation method of composite probiotic feed additive

A feed additive and compound probiotic technology, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve the problems of affecting pig carcass quality, low operation efficiency, and high cost, and improve active food intake, Improves absorption capacity and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

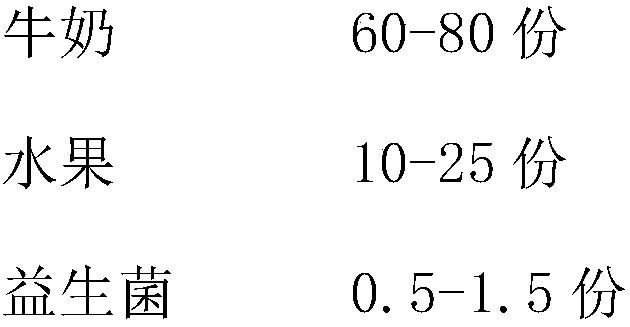

[0052] The raw material of the feed additive provided in this embodiment is made up of the composition of following mass parts:

[0053]

[0054] Wherein, the fresh fruit is composed of cherries, kiwi fruit and grapes, and the mass-to-number ratio of the three is 3:2:1.

[0055] Wherein, the probiotics include Bifidobacterium, Lactobacillus acidophilus and Lactobacillus casei. Preferably, the ratio of the three probiotics is 1:1:1.

[0056]The present embodiment also provides the preparation method of feed additive as above:

[0057] A. Pasteurization is carried out after mixing the fresh milk and the fruit juice after squeezing the juice in the above-mentioned parts by mass to obtain a culture medium stock solution;

[0058] B. Adding the above-mentioned probiotics in parts by mass to the stock solution of the medium for fermentation, the fermentation temperature is 37° C., and the fermentation time is 30 hours, to obtain fermented milk;

[0059] C. The above-mentioned ...

Embodiment 2

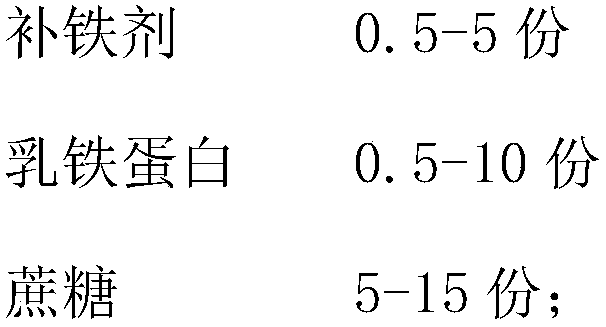

[0062] The raw material of the feed additive provided in this embodiment is made up of the composition of following mass parts:

[0063]

[0064] Wherein, the fresh fruit is composed of cherries, kiwi fruit and grapes, and the mass-to-number ratio of the three is 1:1:1.

[0065] Wherein, the probiotics include Bifidobacterium, Lactobacillus acidophilus and Lactobacillus casei. Preferably, the ratio of the three probiotics is 1:1:1.

[0066] The present embodiment also provides the preparation method of feed additive as above:

[0067] A. Pasteurization is carried out after mixing the fresh milk and the fruit juice after squeezing the juice in the above-mentioned parts by mass to obtain a culture medium stock solution;

[0068] B. adding the above-mentioned probiotics in parts by mass to the stock solution of the medium for fermentation, the fermentation temperature is 35° C., and the fermentation time is 48 hours to obtain fermented milk;

[0069] C. The above-mentioned ...

Embodiment 3

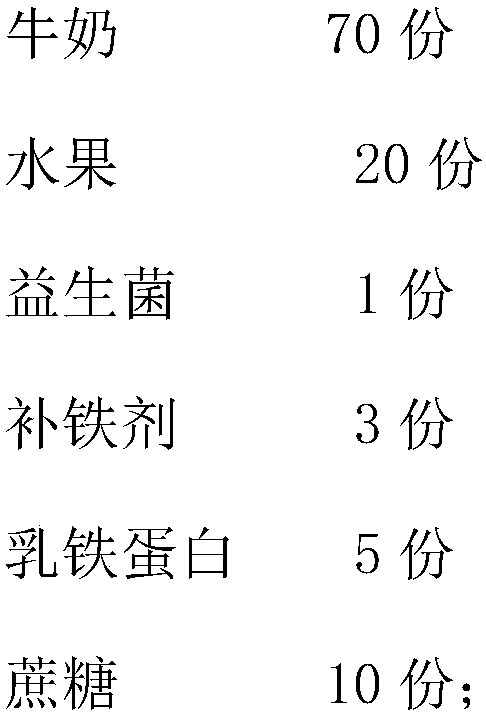

[0072] The raw material of the feed additive provided in this embodiment is made up of the composition of following mass parts:

[0073]

[0074] Wherein, the fresh fruit is composed of cherries, kiwi fruit and grapes, and the mass-to-number ratio of the three is 2:1:1.

[0075] Wherein, the probiotics include Bifidobacterium, Lactobacillus acidophilus and Lactobacillus casei. Preferably, the ratio of the three probiotics is 1:1:1.

[0076] The present embodiment also provides the preparation method of feed additive as above:

[0077] A. Pasteurization is carried out after mixing the fresh milk and the fruit juice after squeezing the juice in the above-mentioned parts by mass to obtain a culture medium stock solution;

[0078] B. Adding the above-mentioned probiotics in parts by mass to the stock solution of the medium for fermentation, the fermentation temperature is 40° C., and the fermentation time is 24 hours, to obtain fermented milk;

[0079] C. The above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com