Adsorption resin for blood perfusion and preparation method thereof, and perfusion device

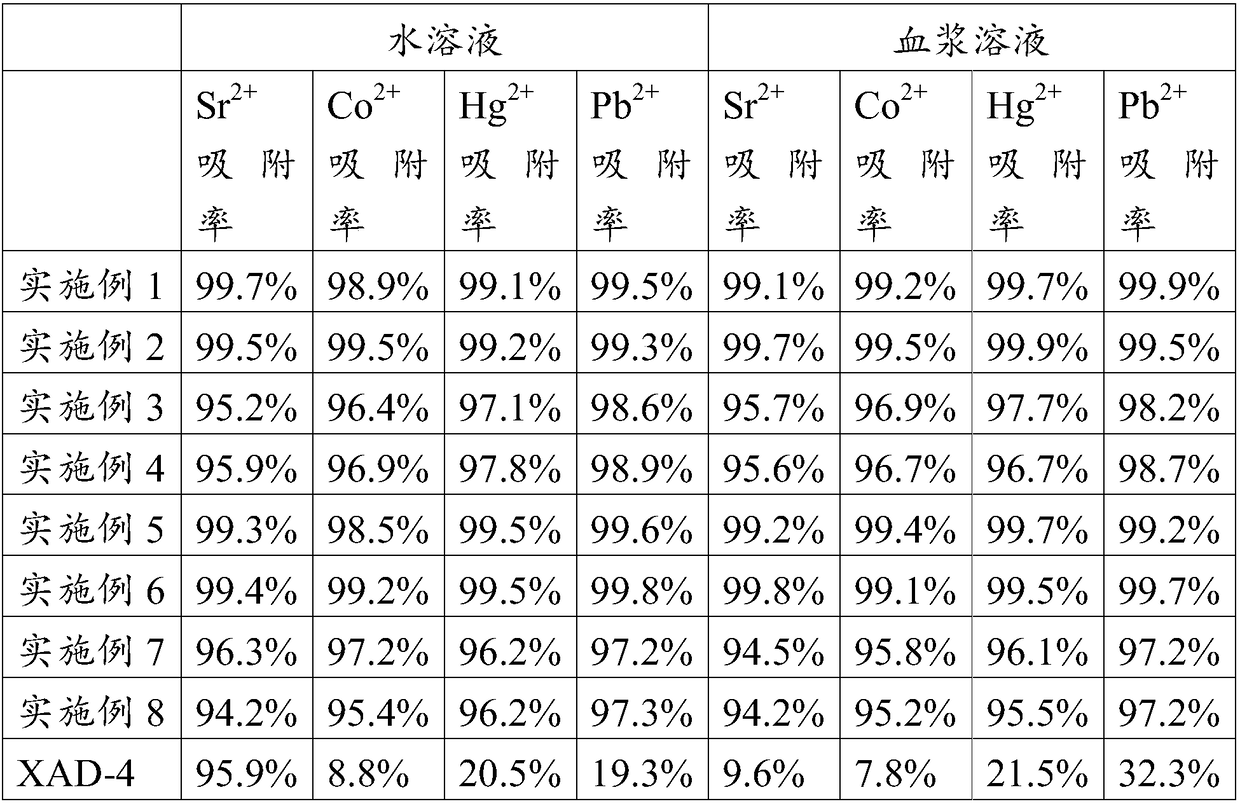

A hemoperfusion and adsorption resin technology, applied in the field of perfusion devices, can solve the problems of toxic side effects, acute kidney poisoning, etc., and achieve the effects of high selectivity, high adsorption rate, and good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The adsorbent resin for hemoperfusion of this embodiment is prepared by the following method:

[0040] (1) Chlorine ball amination

[0041] Mix 500g of cross-linked polystyrene chlorine balls (10% chlorine content), 3000g of dichloroethane and 200g of polyethyleneimine, react at 40°C for 20h, and purify to obtain an aminated polystyrene resin.

[0042] (2) Ligand activation

[0043] Dissolve 500g polycarboxyl chelating agent sodium diethyltriaminepentaacetate in 3000g tetramethylethylenediamine-hydrochloric acid buffer solution, stir evenly at room temperature, regulate and control the solution pH to 4.5, obtain polycarboxylate chelating agent solution; In the mixture solution, add 200g of N-hydroxysulfosuccinimide and 100g of condensing agent 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide, and stir in the dark at 30°C After 24 hours, an activated polycarboxylate chelating agent solution was obtained.

[0044] (3) Grafting

[0045] Stir and mix 100g of aminated polys...

Embodiment 2

[0048] The adsorbent resin for hemoperfusion of this embodiment is prepared by the following method:

[0049] (1) Chlorine ball amination

[0050] Mix 500g of chlorine balls (15% chlorine content), 1000g of dimethyl sulfoxide and 500g of triethylenetetramine, react at 80°C for 2h, and purify to obtain an aminated polystyrene resin.

[0051] (2) Ligand activation

[0052] Dissolve 500g of polycarboxyl chelating agent diethyltriaminepentaacetic acid in 2000g of acetic acid-sodium acetate buffer solution, stir evenly at room temperature, and adjust the pH of the solution to 3.8 to obtain a polycarboxyl chelating agent solution; in the polycarboxyl chelating agent solution, add 800 g of N-hydroxysulfosuccinimide and 1000 g of condensing agent dicyclohexylcarbodiimide were stirred and reacted at 50°C for 2 hours in the dark to obtain an activated polycarboxylate chelating agent solution.

[0053] (3) Grafting

[0054] Stir and mix 100g of aminated polystyrene resin obtained in s...

Embodiment 3

[0056] The adsorbent resin for hemoperfusion of this embodiment is prepared by the following method:

[0057] (1) Chlorine ball amination

[0058] Mix 500g of chlorine balls (chlorine content is 0.5%), 500g of N,N-dimethylformamide and 5g of N-hydroxyethylethylenediamine, react at 20°C for 40h, and purify to obtain aminated polyphenylene Vinyl.

[0059] (2) Ligand activation

[0060] 500g polycarboxyl chelating agent sodium ethylenediaminetetraacetate is dissolved in 5000g tetramethylethylenediamine / hydrochloric acid buffer solution, stir at room temperature, control solution pH to 3, obtain polycarboxyl chelating agent solution; 50 g of N-hydroxysulfosuccinimide and 5000 g of condensing agent N,N-diisopropylcarbodiimide were added, and stirred and reacted at 35° C. in the dark for 12 hours to obtain an activated polycarboxylate chelating agent solution.

[0061] (3) Grafting

[0062] Stir and mix 100g of aminated polystyrene resin obtained in step (1) with 1000g of water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com