Multi-purpose glue used in decoration engineering and its preparation method and application

A multi-purpose glue, light calcium technology, applied in the direction of adhesive, epoxy resin glue, unsaturated alcohol copolymer adhesive, etc., can solve the problems of easy dusty construction site, poor flatness of putty, long construction period, etc. , to shorten the construction period, facilitate renovation and construction, save material costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

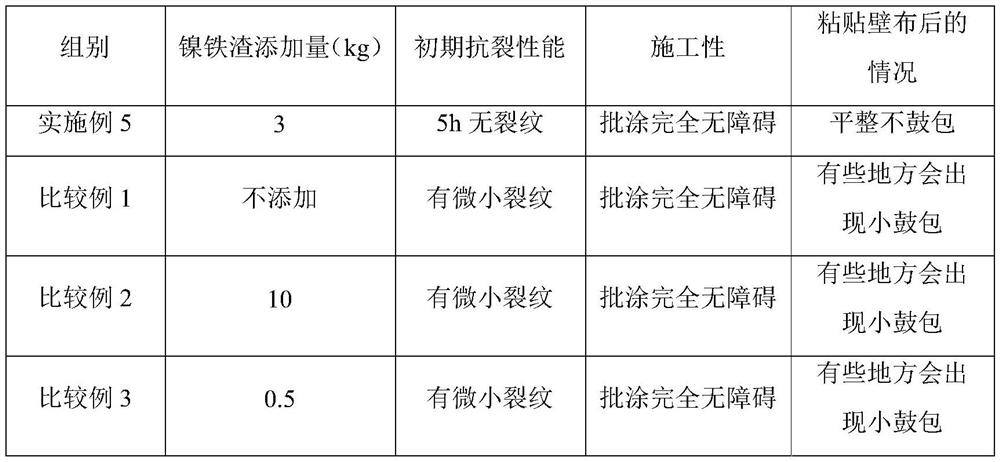

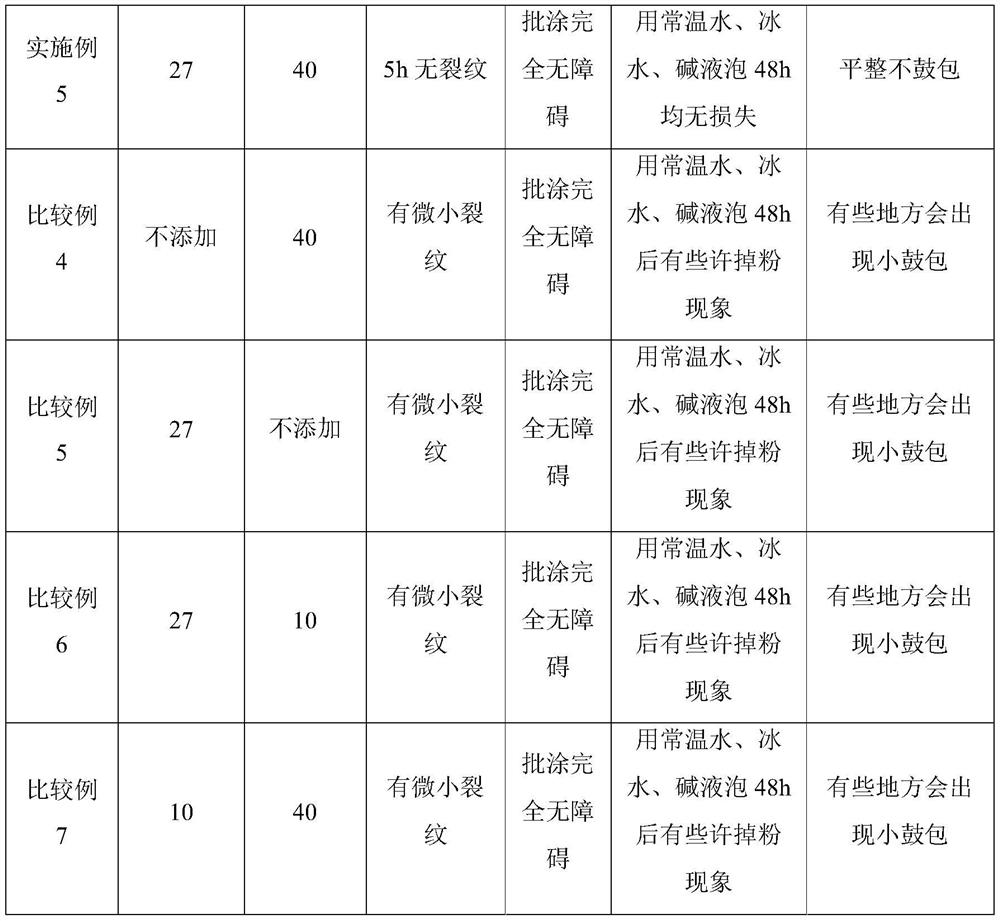

Examples

Embodiment 1

[0038] The raw materials of the multi-purpose glue are proportioned according to the following quality:

[0039] Light calcium 30kg, heavy calcium 40kg, talc powder 10kg, emulsion 20kg, slag 25kg, fly ash 45kg, polyvinyl alcohol 4kg, cellulose 3kg, ethylene glycol 1kg, nickel iron slag 4kg, diatom mud 7kg, lanthanum cerium metal 0.4kg, 4kg of epoxy resin, 5kg of magnetic filler (soft magnetic powder), 3kg of commonly used additives (film forming aids, defoamers, preservatives), and 10kg of purified water;

[0040] The preparation method is as follows:

[0041] 1) First add light calcium, heavy calcium, talcum powder, emulsion, slag, fly ash, polyvinyl alcohol, cellulose, ethylene glycol, nickel iron slag and 2 / 3 amount of pure water into the mixing tank, while stirring While keeping the temperature at room temperature;

[0042] 2) Add diatom mud, lanthanum cerium metal, epoxy resin, magnetic conductive fillers, and common additives (film forming aids, defoamers, preservatives) into t...

Embodiment 2

[0044] The raw materials of the multi-purpose glue are proportioned according to the following quality:

[0045] Light calcium 40kg, heavy calcium 30kg, talcum powder 20kg, emulsion 10kg, slag 30kg, fly ash 35kg, polyvinyl alcohol 7kg, cellulose 1kg, ethylene glycol 3kg, nickel iron slag 2kg, diatom mud 5kg, lanthanum cerium metal 0.7kg, epoxy resin 2kg, magnetic conductive filler (soft magnetic powder) 8kg, commonly used additives (dispersant, film-forming aid, pH regulator, defoamer, preservative and antioxidant) 5kg, pure water 30kg;

[0046] The preparation method is as follows:

[0047] 1) First add light calcium, heavy calcium, talcum powder, emulsion, slag, fly ash, polyvinyl alcohol, cellulose, ethylene glycol, nickel iron slag and all pure water into the mixing tank, and the temperature is stabilized while stirring At room temperature, the stirring time is 10h;

[0048] 2) Add diatom mud, lanthanum and cerium metal, epoxy resin, magnetic conductive filler, and commonly used ...

Embodiment 3

[0050] The raw materials of the multi-purpose glue are proportioned according to the following quality:

[0051] Light calcium 32kg, heavy calcium 38kg, talcum powder 12kg, emulsion 18kg, slag 26kg, fly ash 42kg, polyvinyl alcohol 5kg, cellulose 2.5kg, ethylene glycol 1.5kg, nickel iron slag 3.5kg, diatom mud 5.5kg , Lanthanum cerium metal 0.6kg, epoxy resin 2.5kg, magnetic conductive filler (soft magnetic powder) 6kg, commonly used additives (according to dispersant, film-forming additives, pH regulators, defoamers, preservatives, antioxidants Add sequentially) 3.5kg, 25kg of purified water;

[0052] The preparation method is as follows:

[0053] 1) First add light calcium, heavy calcium, talcum powder, emulsion, slag, fly ash, polyvinyl alcohol, cellulose, ethylene glycol, nickel iron slag and all pure water into the mixing tank, and the temperature is stabilized while stirring At room temperature, the stirring time at 500rpm is 18h;

[0054] 2) Add diatom mud, lanthanum and ceriu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com