Preparation technology of lysine fermentation medium

A lysine fermentation and culture medium technology, which is applied in the field of amino acid fermentation, can solve the problems of low lysine yield and high cost of fermentation medium, and achieve the effect of easy enzymolysis, low cost and reduced enterprise cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

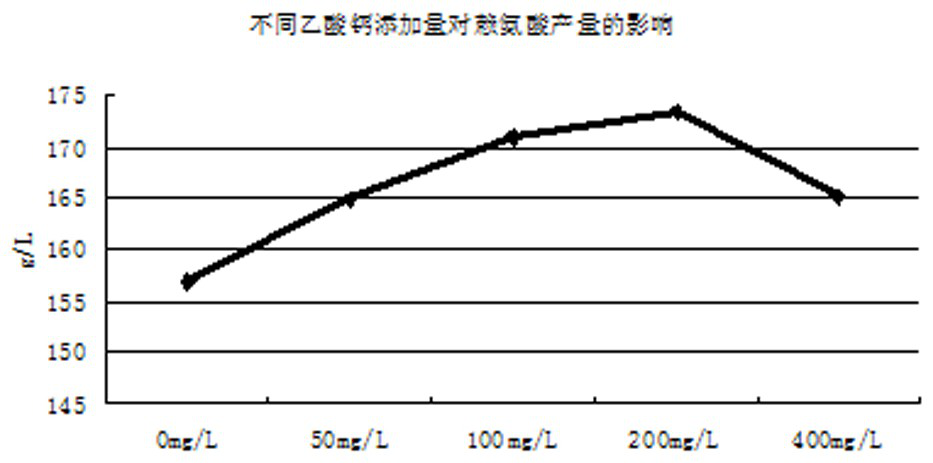

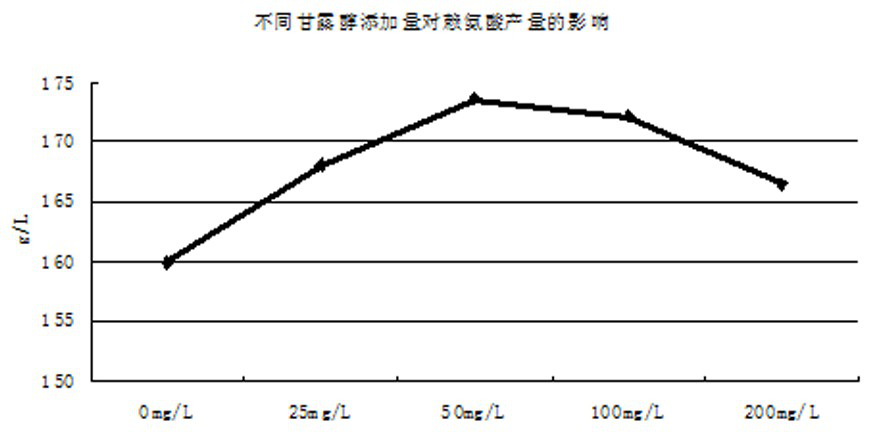

Examples

Embodiment 1

[0027] A lysine fermentation medium, which comprises the following components:

[0028] Corn husk treatment 300g / L, corn steep liquor 10g / L, potassium dihydrogen phosphate 2g / L, dipotassium hydrogen phosphate 2g / L, ferrous sulfate heptahydrate 0.2g / L, magnesium sulfate heptahydrate 0.2g / L, acetic acid Calcium 200mg / L, Mannitol 50mg / L, Biotin 10mg / L, Vitamin B 1 2mg / L, the solvent is water;

[0029] The preparation process is as follows: adding various raw materials into water, adjusting the pH to 6.8, sterilizing at 121° C. for 20 minutes, and cooling to 32° C. to obtain the product.

[0030] The fermentation process using the above-mentioned fermentation medium includes the following steps: placing the fermentation medium in a fermenter, then inserting the strain seed liquid according to the inoculation amount of 12%, controlling the temperature at 32°C, the tank pressure at 0.05MPa, and the air volume at 600L / h, the rotation speed is 350rpm, the pH is controlled at 6.8, t...

Embodiment 2

[0036]A lysine fermentation medium, which comprises the following components:

[0037] Corn husk treatment 200g / L, corn steep liquor 20g / L, potassium dihydrogen phosphate 1g / L, dipotassium hydrogen phosphate 1g / L, ferrous sulfate heptahydrate 0.1g / L, magnesium sulfate heptahydrate 0.1g / L, acetic acid Calcium 100mg / L, Mannitol 100mg / L, Biotin 5mg / L, Vitamin B 1 1mg / L, the solvent is water;

[0038] The preparation process is as follows: adding various raw materials into water, adjusting the pH to 6.8, sterilizing at 121° C. for 20 minutes, and cooling to 32° C. to obtain the product.

[0039] The fermentation process using the above-mentioned fermentation medium includes the following steps: placing the fermentation medium in a fermenter, then inserting the strain seed liquid according to the inoculum amount of 10%, controlling the temperature at 32°C, the tank pressure at 0.05MPa, and the air volume at 600L / h, the rotation speed is 350rpm, the pH is controlled at 6.8, the d...

Embodiment 3

[0054] Using Corynebacterium glutamicum ATCC14997 as the fermentation strain, the amount of lysine produced by fermentation in Example 1 and Comparative Examples 1-3 was studied. The fermentation process was referred to in Example 1. The specific acid production by fermentation is shown in Table 1:

[0055] Table 1

[0056] group Example 1 Comparative example 1 Comparative example 2 Comparative example 3 Lysine production g / L 173.5 147.8 162.9 151.7

[0057] As shown in Table 1, the amount of acid production in Example 1 is the highest, which is 17.4% higher than that of Comparative Example 1, 6.5% higher than that of Comparative Example 2, and 14.3% higher than that of Comparative Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com