Vanadium modified Cu2S self-supported electrode material, and synthesis method thereof

A technology of self-supporting electrode and synthesis method, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of harsh reaction conditions, complicated operation steps, complicated preparation process, etc., and achieve low synthesis temperature, cheap and easy-to-obtain raw materials , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

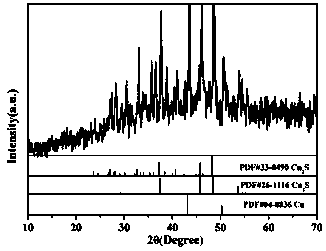

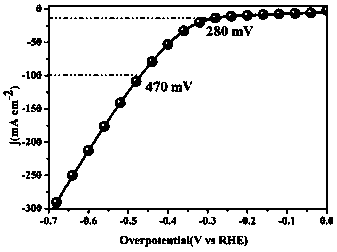

Image

Examples

Embodiment 1

[0025] (1) Soak the (2×5) cm foam copper in acetone for 5 minutes, then immerse it in 1 mol / L hydrochloric acid for 5 minutes, and finally wash it with ethanol and deionized water alternately for 3 times , after vacuum drying at 20 ℃ for 5 h, the treated copper foam was obtained;

[0026] (2) Choose sodium dodecahydrate vanadate and thioacetamide as raw materials, take sodium dodecahydrate vanadate as 0.2mmol, control the molar ratio of vanadium source and sulfur source to 1:1, and add it to 20 ml anhydrous In ethanol, stir magnetically at room temperature for 3 min to obtain suspension A;

[0027] (3) Put the stirred suspension A and the pretreated foamed copper in step (1) into a 50 mL polytetrafluoroethylene liner to seal, then put it in a homogeneous reactor for reaction, and react at 70°C The reaction time is 1 h;

[0028] (4) After the reaction was completed and cooled, the product was washed alternately with deionized water and ethanol three times, and then vacuum-dri...

Embodiment 2

[0030] (1) Soak the (2×5) cm foam copper in acetone for 5 minutes, then immerse it in 2 mol / L hydrochloric acid for 5 minutes, and finally wash it with ethanol and deionized water alternately for 3 times , after vacuum drying at 20 ℃ for 10 h, the treated copper foam was obtained;

[0031] (2) Choose sodium dodecahydrate vanadate and thioacetamide as raw materials, take sodium dodecahydrate vanadate as 0.4 mmol, control the molar ratio of vanadium source and sulfur source to 1:1, and add it to 25 ml anhydrous In the mixture of ethanol and water, stir magnetically at room temperature for 5 minutes to obtain suspension A;

[0032] (3) Put the stirred suspension A and the pretreated copper foam in step (1) into a 50 mL polytetrafluoroethylene liner to seal, then place it in a homogeneous reactor for reaction, and react at 100°C The time is to react under the condition of 5 h;

[0033] (4) After the reaction was completed and cooled, the product was washed alternately with deion...

Embodiment 3

[0035] (1) Soak the (2×5) cm foam copper in acetone for 5 minutes, then immerse it in 3mol / L hydrochloric acid for 10 minutes, and finally wash it with ethanol and deionized water alternately for 3 times. After vacuum drying at 30 °C for 5 h, the treated copper foam was obtained;

[0036] (2) Select sodium dodecahydrate vanadate and thioacetamide as raw materials, take 0.8 mmol of sodium dodecahydrate vanadate, control the molar ratio of vanadium source and sulfur source to 1:2, and add it to 30 ml of methanol at the same time , magnetically stirred at room temperature for 10 min to obtain suspension A;

[0037] (3) Put the stirred suspension A and the pretreated copper foam in step (1) into a 50 mL polytetrafluoroethylene liner to seal, then place it in a homogeneous reactor for reaction, and react at 120°C The time is to react under the condition of 10 h;

[0038] (4) After the reaction was completed and cooled, the product was washed alternately with deionized water and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com