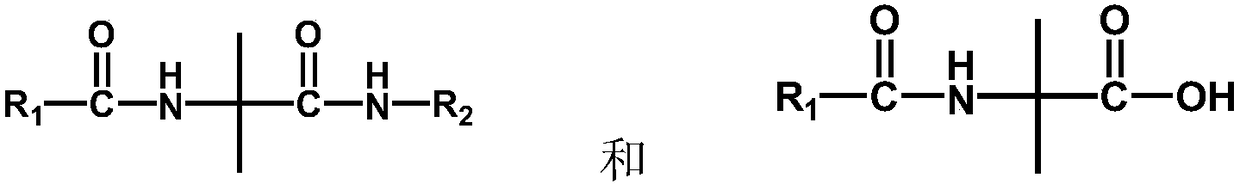

Azlactone-based polyamide membrane and preparation method thereof

A technology of ester-based polyamide membrane and based polyamide membrane, which is applied in the field of nanofiltration membranes and can solve the problems of low metal cation rejection rate, large membrane surface roughness, and poor pollution resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

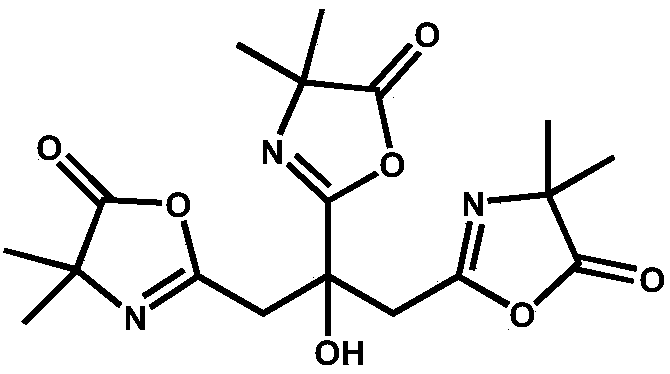

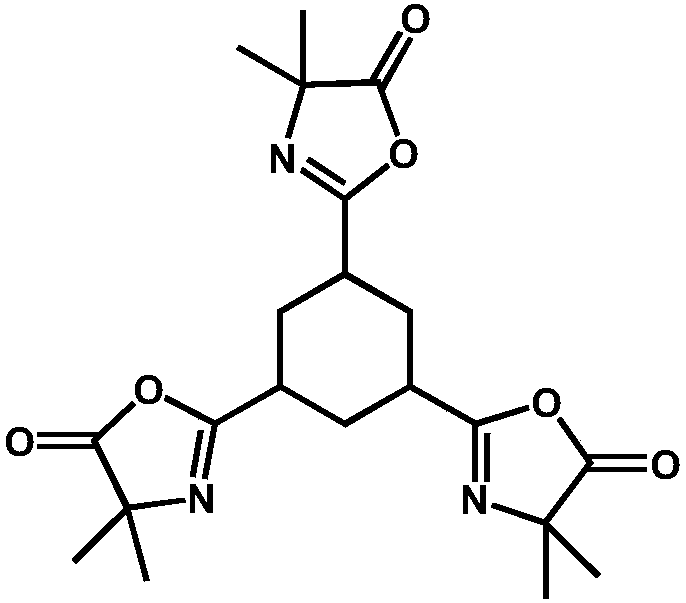

[0067] The preparation method of the azlactone-based polyamide film of the present embodiment comprises the following steps:

[0068] (1) Soak the polyethersulfone ultrafiltration bottom membrane in polyethyleneimine (Mw=70,000) containing 2wt% for 4 minutes, and then purge the gas for 3 minutes to remove excess aqueous amine solution;

[0069] (2) Soak the polyethersulfone ultrafiltration membrane with polyethyleneimine solution prepared in step (1) in 1,3,5-tris-4,4-dimethylacridine containing 0.1 wt% Esterbenzene / cyclohexane solution, the interfacial polymerization time is 120s, and then the prepared polyamide nanofiltration membrane is treated at 60°C for 15min to obtain an azlactone-based polyamide membrane.

[0070] Table 1 shows the salt rejection performance of the azlactone-based polyamide membrane prepared by interfacial polymerization of 1,3,5-tris-4,4-dimethylazlactone and polyethyleneimine in the embodiment of the present invention; Test conditions: cross-flow te...

Embodiment 2

[0074] The preparation method of the azlactone-based polyamide film of the present embodiment comprises the following steps:

[0075] (1) Soak the polyethersulfone ultrafiltration bottom membrane in an aqueous solution containing 1.5wt% tris(2-aminoethyl)amine for 4 minutes, and then purging the gas for 3 minutes to remove excess aqueous phase solution;

[0076] (2) Soak the polyethersulfone ultrafiltration membrane with tris(2-aminoethyl)amine solution prepared in step (1) in 1,3,5-tris-4,4-bis Methylazlactone benzene / cyclohexane solution, the interfacial polymerization time is 60s, and then the prepared polyamide nanofiltration membrane is treated at 60°C for 15min to obtain an azlactone-based polyamide membrane.

[0077] Table 2 shows the salt rejection performance of the polyamide nanofiltration membrane prepared by interfacial polymerization of 1,3,5-tris-4,4-dimethylazlactone and tris(2-aminoethyl)amine; test conditions : Cross-flow test, the single salt solution is 200...

Embodiment 3

[0081] The preparation method of the azlactone-based polyamide film of this example is different from that of Examples 1 and 2. In this example, the monomer containing an azlactone structure is mixed with an acid chloride monomer oil phase solution, and then reacted with an amine to obtain An azlactone-based polyamide membrane, comprising the steps of:

[0082] (1) Soak the polysulfone ultrafiltration bottom membrane in an aqueous solution containing 1wt% piperazine for 2 minutes, after which, gas purge for 2 minutes to remove excess aqueous phase solution;

[0083] (2) Soak the polysulfone ultrafiltration membrane of the piperazine aqueous solution prepared in step (1) in a solution containing 0.025wt% 1,3,5-trimesine-4,4-dimethylazlactone and 0.15wt% 1,3,5-trimesoyl chloride benzene / cyclohexane solution, wherein the mass fraction of 1,3,5-tris-4,4-dimethylazlactone is 0.025wt%, 1, The mass fraction of 3,5-trimesoyl chloride is 0.15wt%, the mass fraction of solvent benzene i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com