Series of halogen element-doped covalent triazine organic polymer visible light photocatalysts and preparation and application thereof

A halogen element and covalent triazine technology is applied in the field of halogen element doped covalent triazine organic polymer visible light photocatalyst and its preparation, which can solve the problem of high photogenerated carrier recombination rate, restricted application and quantum efficiency. low problems, to achieve the effect of simple and convenient preparation method, high practical value and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

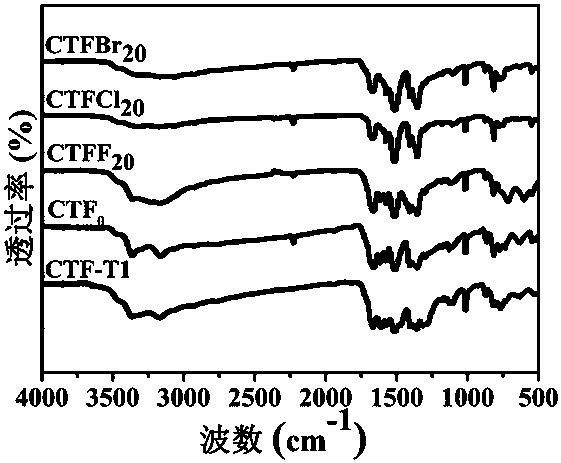

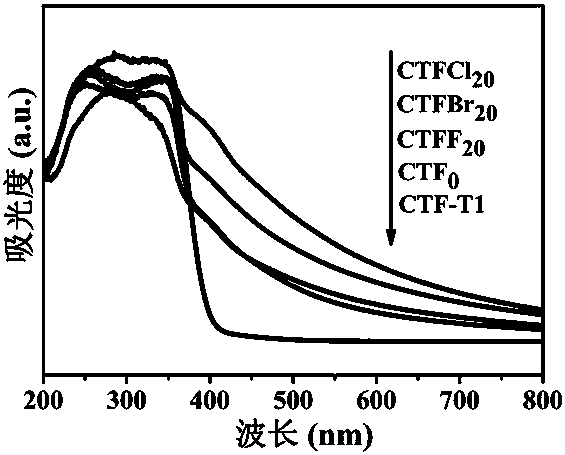

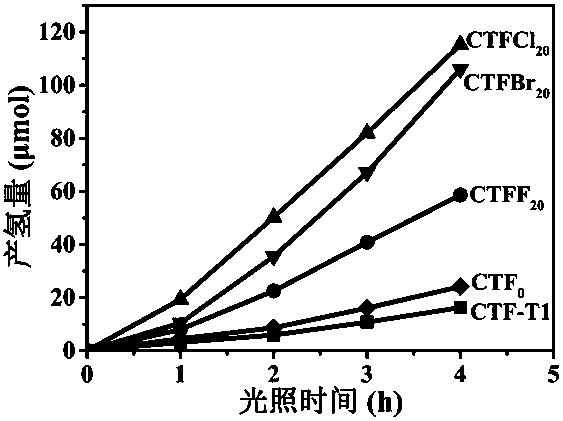

[0024] Example 1: Preparation of halogen element doped covalent triazine organic polymer visible light photocatalyst

[0025] Weigh 4 g of ammonium fluoride and 0.2 g of covalent triazine organic polymer and mix them in 30 mL of distilled water, ultrasonically disperse for 0.5 h, and then heat to remove water in an oil bath at 90 °C; the obtained solid is heated in a muffle furnace at 250 °C Calcined under the same conditions for 2 h; after naturally cooling to room temperature, the sintered solid was ground into powder, and refluxed with methanol at 90 °C for 12 h; the refluxed sample was washed and centrifuged until the ion concentration was less than 10 ppm, and dried at 60 °C for 12 h. After h, 20% fluorine-doped covalent triazine organic polymer visible light photocatalyst was obtained, denoted as CTFF 20 .

Embodiment 2

[0026] Example 2: Preparation of halogen element doped covalent triazine organic polymer visible light photocatalyst

[0027] Weigh 4 g of ammonium chloride and 0.2 g of covalent triazine organic polymer and mix them in 30 mL of distilled water, ultrasonically disperse for 0.5 h, then heat to remove water in an oil bath at 90 °C; Calcined under the same conditions for 2 h; after naturally cooling to room temperature, the sintered solid was ground into powder, and refluxed with methanol at 90 °C for 12 h; the refluxed sample was washed and centrifuged until the ion concentration was less than 10 ppm, and dried at 60 °C for 12 h. After h, 20% chlorine-doped covalent triazine organic polymer visible light photocatalyst was obtained, denoted as CTFCl 20

Embodiment 3

[0028] Example 3: Preparation of halogen element doped covalent triazine organic polymer visible light photocatalyst

[0029] Weigh 4 g of ammonium bromide and 0.2 g of covalent triazine organic polymer and mix them in 30 mL of distilled water, ultrasonically disperse for 0.5 h, and then heat to remove moisture in an oil bath at 90 °C; the obtained solid is heated in a muffle furnace at 250 °C Calcined under the same conditions for 2 h; after naturally cooling to room temperature, the sintered solid was ground into powder, and refluxed with methanol at 90 °C for 12 h; the refluxed sample was washed and centrifuged until the ion concentration was less than 10 ppm, and dried at 60 °C for 12 h. After h, 20% bromine-doped covalent triazine organic polymer visible light photocatalyst was obtained, denoted as CTFBr 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com