High-fluorine wear-resistant self-lubricating material

A self-lubricating material and high fluorine technology, applied in the field of material manufacturing, can solve problems such as poor product stability, high impurity content, and material structural performance degradation, and achieve low production costs, low impurity content, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

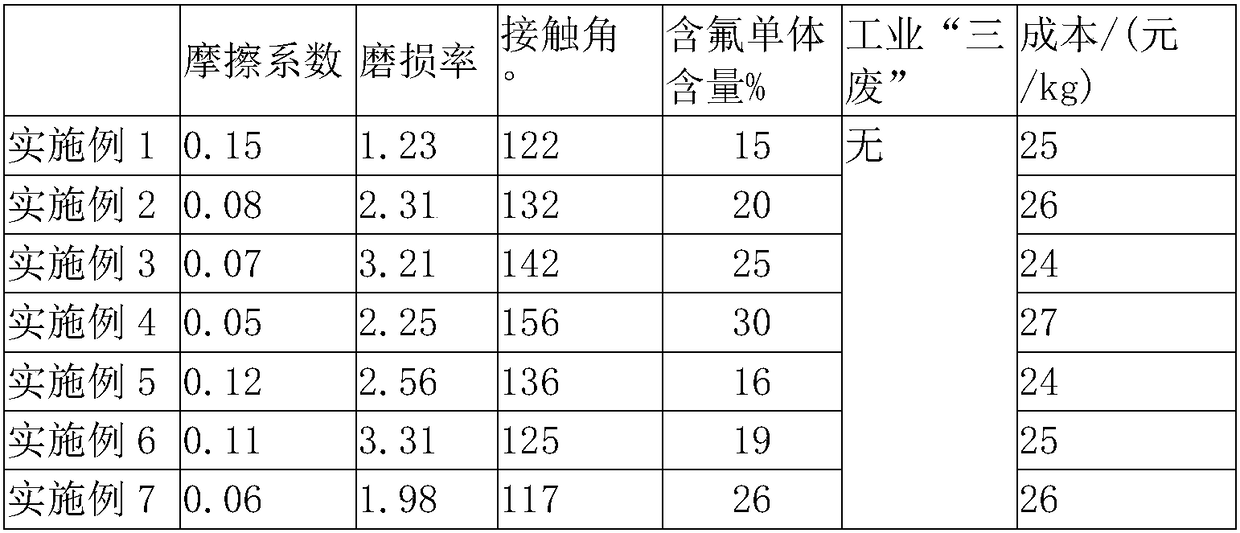

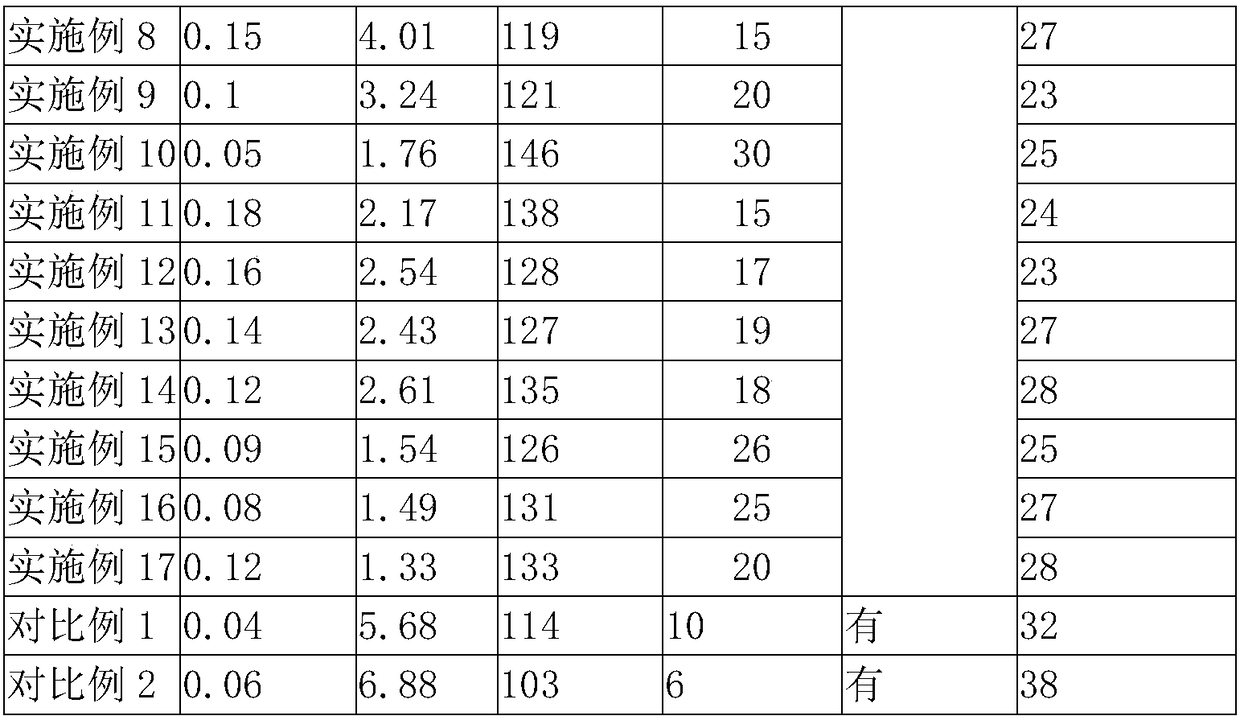

Examples

Embodiment 1

[0021] Add 900 g of polycaprolactone polyol, 6.2 g of ethylene glycol, and 199.1 g of allyl heptafluoroisopropyl ether into the container. Use a high-speed stirrer to stir at 1000 rpm for 10 minutes, and then add 222 g of isophorone The isocyanate was stirred at 500 rpm for 2 minutes and then put into the curing box for curing at 100 degrees Celsius for 10 hours to obtain material 1.

Embodiment 2

[0023] Add 900 g of polycaprolactone polyol, 9 g of 1,4-butanediol, and 276.4 g of allyl pentafluorobenzene into the container. Use a high-speed stirrer to stir for 8 minutes at 1100 rpm, and then add 196.5 g of dicyclohexyl methane The diisocyanate was stirred at 600 rpm for 5 minutes and then put into a curing box for curing at a temperature of 100 degrees Celsius for 10 hours to obtain material 2.

Embodiment 3

[0025] Add 900g of polycaprolactone polyol, 13.4g of dipropylene glycol, 357.7g of 1H,1H-heptafluorobutylmethacrylamide into the container, use a high-speed stirrer to stir at 1500rpm for 10min, and then add 159.8g of benzodiazepine Methyl diisocyanate was stirred at 700 rpm for 2 minutes and then put into a curing box for curing at a temperature of 100 degrees Celsius for 12 hours to obtain material 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com