LED light source for spectrophotometer and preparation method of LED light source

A technology of LED light source and spectrophotometer, which is applied in the field of analytical instruments, can solve problems such as short service life, poor test results, and troublesome instrument design, and achieve the effects of simplifying instrument design, improving stability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The chemical formula of the near-infrared phosphor used is Ca 1.96 Mg 0.999 WO 6 :0.02Bi 3+ ,0.001Cr 3+ . The preparation method of the fluorescent powder comprises the following steps:

[0052] (1) Press Ca 1.96 Mg 0.999 WO 6 :0.02Bi 3+ ,0.001Cr 3+ stoichiometric ratio, accurately weigh the raw material CaCO 3 、WO 3 , MgO, Bi 2 o 3 and Cr(NO 3 ) 3 , placed in an agate mortar and thoroughly ground and mixed to obtain a raw material mixture;

[0053] (2) The raw material mixture obtained in step (1) is placed in a corundum crucible and moved into a muffle furnace. Raise the muffle furnace to 600°C and keep it at a constant temperature for 2h;

[0054] (3) After cooling the sample obtained in step (2), take out the sample and grind it again, then sinter at 1300°C for 5h, cool down to room temperature with the furnace, and grind the obtained sintered body into powder.

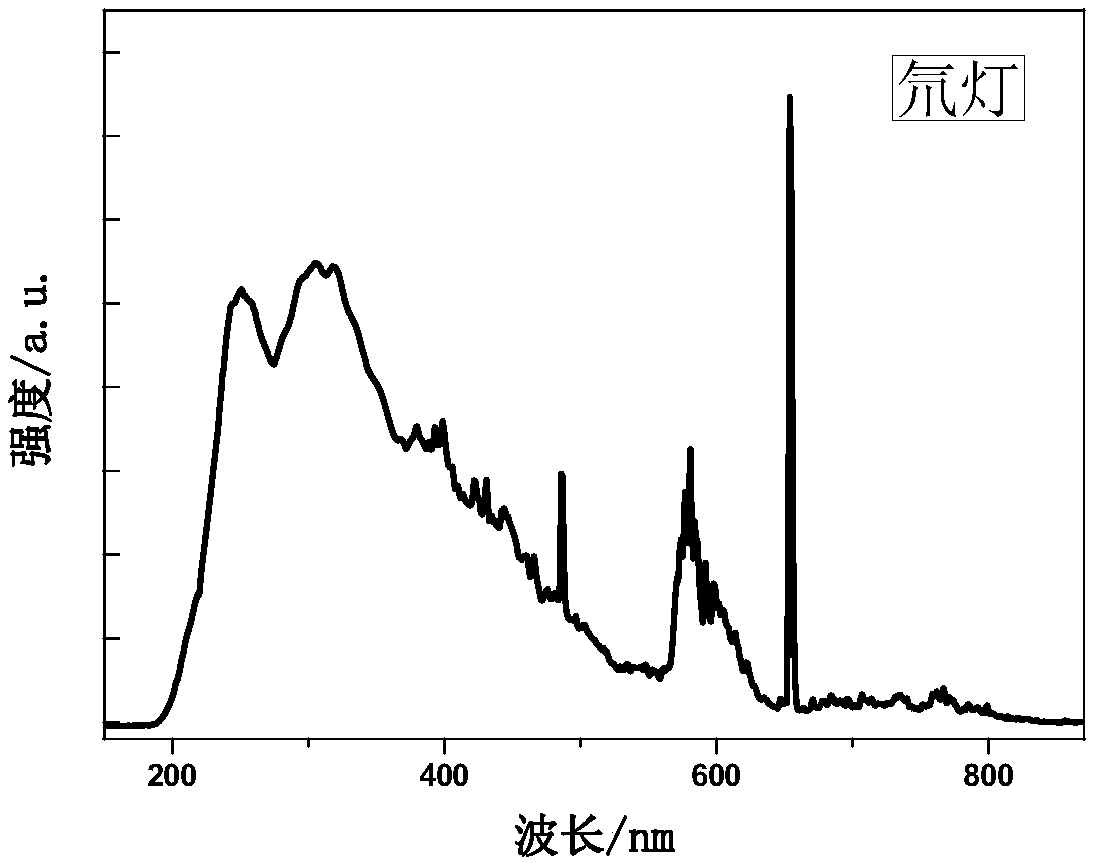

[0055] Its emission spectrum is as Figure 7 shown.

[0056] The emission wavelength...

Embodiment 1

[0058] A method for preparing an LED light source for a spectrophotometer, comprising the steps of:

[0059] (1) Mix 15 mg of blue phosphor, 40 mg of green phosphor, 1 mg of red phosphor and 600 mg of near-infrared phosphor, grind and mix them in an agate mortar to obtain a mixed phosphor;

[0060] (2) Take the container, add 1g of silica gel (Momentive, IVS4542) and stir with a glass rod for 5 minutes, then add the mixed fluorescent powder obtained in step (1), stir with a glass rod for 5 minutes, and vacuum defoam for 4 hours to obtain a mixed fluorescent colloid;

[0061] (3) Take 0.2 g of the mixed fluorescent colloid obtained in step (2) and apply it on the surface of the ultraviolet LED chip with a thickness of 0.1 cm;

[0062] (4) Curing: Bake the colloid-coated UV chip at 100°C for 1 hour, then raise the temperature to 150°C and bake for 3 hours to obtain the LED light source for the spectrophotometer. The resulting spectrophotometer uses an LED light source such as ...

Embodiment 2

[0064] A method for preparing an LED light source for a spectrophotometer, comprising the steps of:

[0065] (1) Mix 12 mg of blue phosphor, 35 mg of green phosphor, 0.8 mg of red phosphor and 500 mg of near-infrared phosphor, grind and mix them in an agate mortar to obtain a mixed phosphor;

[0066] (2) Take the container, add 1g of silica gel (Momentive, IVS4542), stir evenly with a glass rod for 5min, then add the mixed fluorescent powder obtained in step (1), stir evenly with a glass rod for 5min, and then vacuum defoam for 4h to obtain a mixed fluorescent colloid;

[0067] (3) Take 0.3 g of the mixed fluorescent colloid obtained in step (2) and apply it on the surface of the ultraviolet LED chip, with a thickness of 0.2 cm;

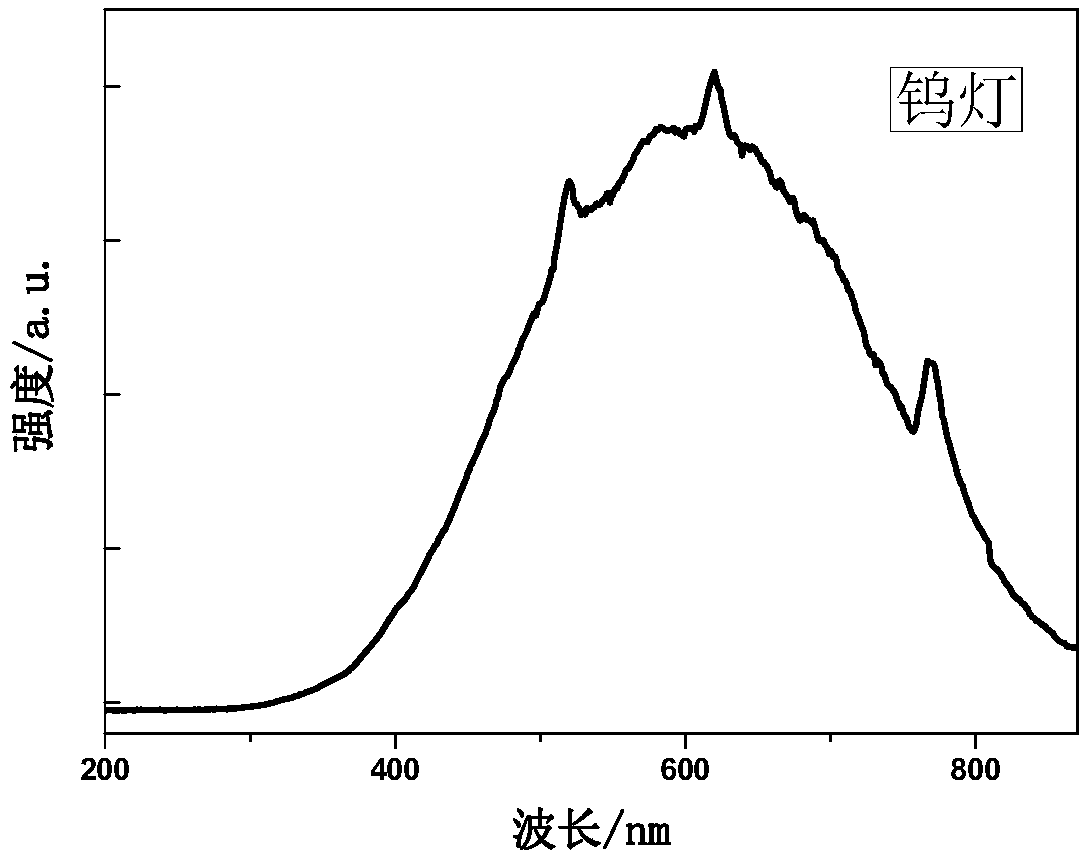

[0068] (4) Curing: Bake the colloid-coated UV chip at 100°C for 1 hour, then raise the temperature to 150°C and bake for 3 hours to obtain the LED light source for the spectrophotometer. Its emission spectrum is as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com