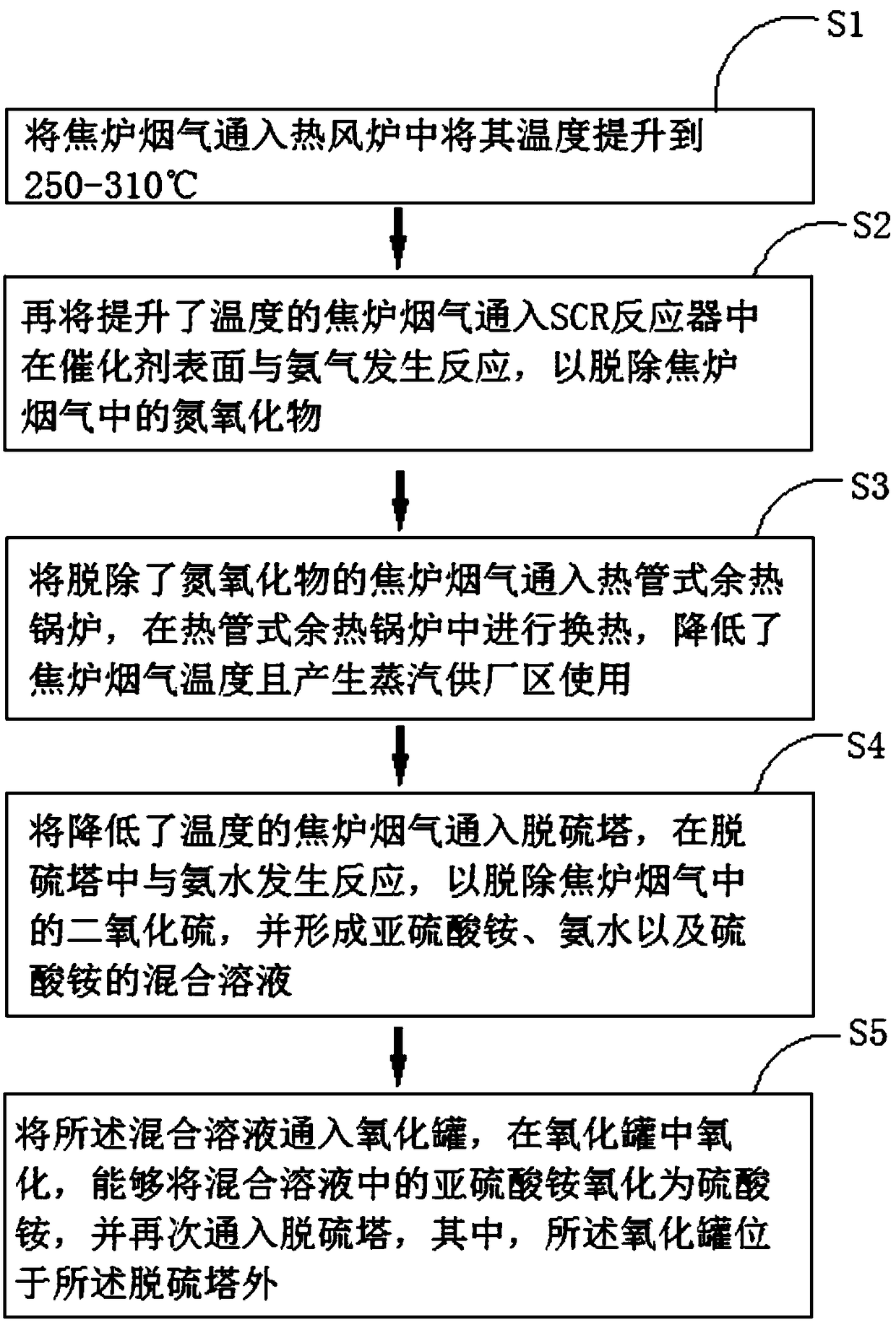

Coke oven flue gas desulphurization denitration method

A desulfurization, denitrification and coke oven technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of secondary environmental pollution, escape, difficult load changes, etc., to save operating costs and control ammonia escape rate. , the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

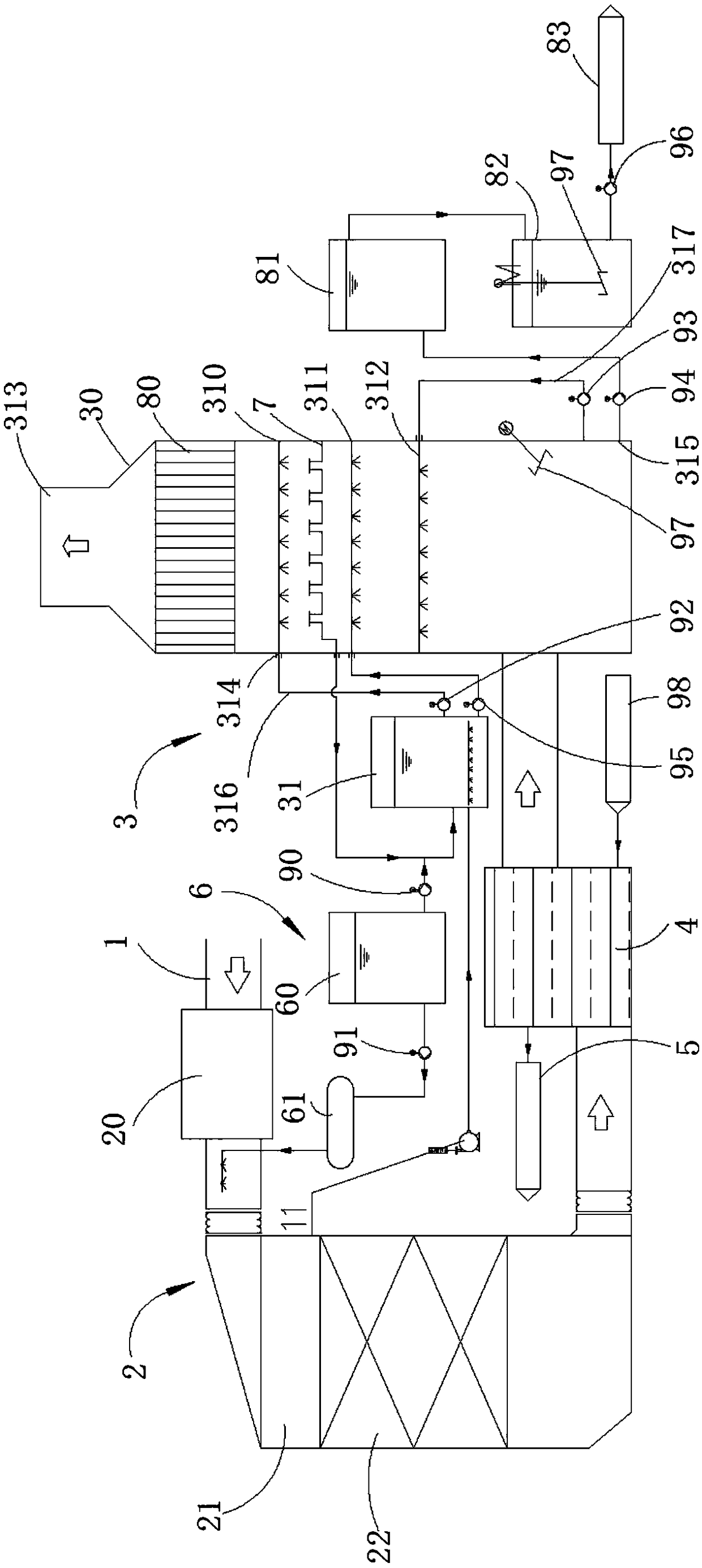

[0035] As an optimization scheme of the embodiment of the present invention, please refer to figure 2 , using an ammonia water tank to provide ammonia to the SCR reactor at the same time, and to provide ammonia to the desulfurization tower; wherein, when providing ammonia to the SCR reactor, the ammonia in the ammonia tank is first passed into the ammonia evaporator, The obtained ammonia gas is then fed into the SCR reactor. When ammonia water is provided to the desulfurization tower, the ammonia water in the ammonia water tank can be directly passed into the oxidation tank, and then into the desulfurization tower through the oxidation tank. In this way, ammonia water and ammonia gas can be simultaneously provided by the same ammonia water tank, which saves production cost.

[0036] To further optimize the above scheme, when the ammonia gas is passed into the SCR reactor, when the ammonia water is passed into the oxidation tank, and when the ammonia water is passed into the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com