A microwave curing molding system for water-soluble cores

A microwave curing, water-soluble core technology, applied in the direction of core, mold components, casting and molding equipment, etc., can solve the problems of low core strength, short service life, long preparation cycle, etc., to avoid scratches and ensure strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

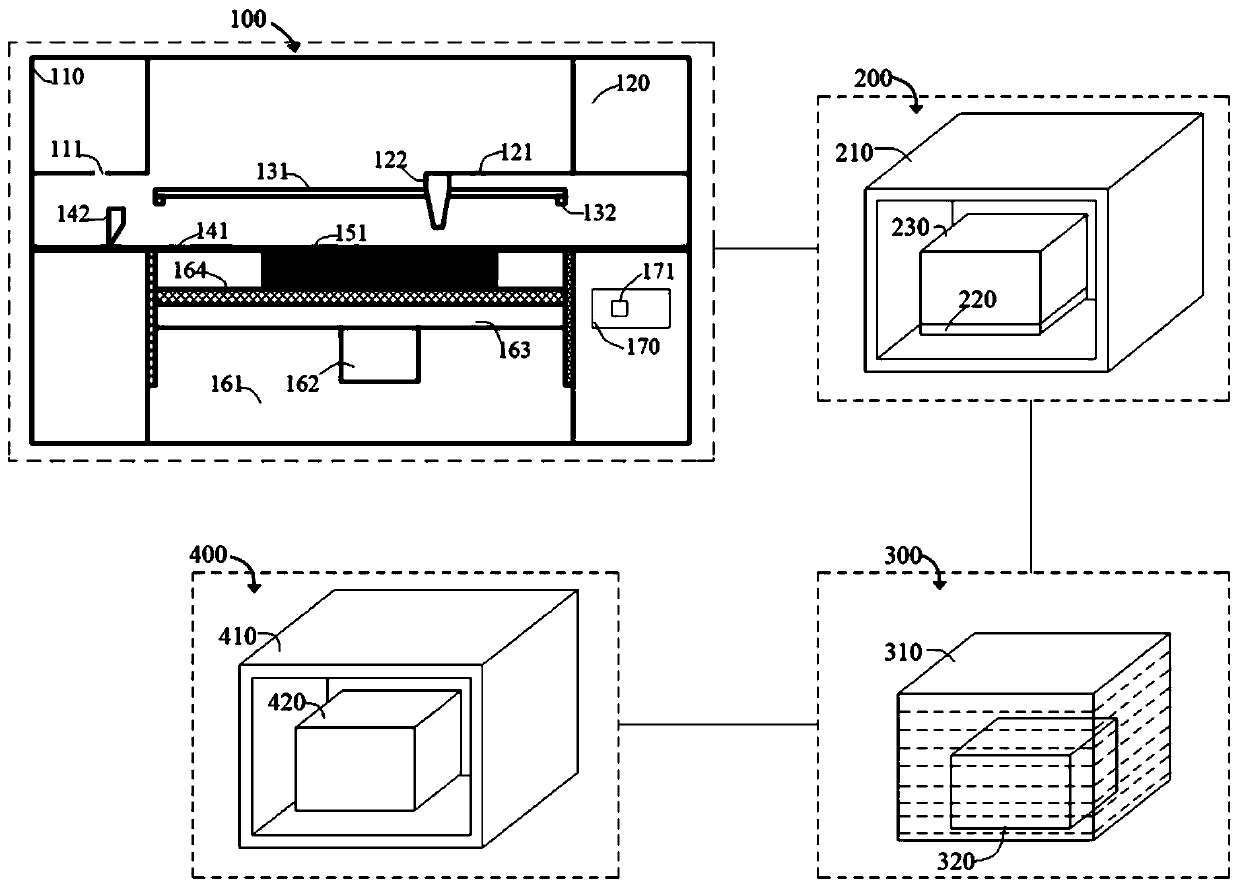

[0036] Refer to attached figure 1 with figure 2As shown, a microwave curing molding system for a water-soluble core in this embodiment includes a molding sand spraying unit 100, a core curing unit 200, a core soaking unit 300 and a core sintering unit 400, and the molding sand spraying unit 100 includes a matching Liquid tank 120, liquid spraying device 122 and material laying device 142, the liquid distribution tank 120 is used to store the configured spray liquid, the material spreading device 142 is used to lay the molding sand, and the liquid spraying device 122 is laid layer by layer according to the layer thickness of 0.01 ~ 1mm The good molding sand is sprayed with spray liquid, and the spray liquid makes the molding sand gather and condense to form the core 230 to be cured; the core curing unit 200 is used to perform two intermittent microwave heating and curing on the solidified core 230 to become the solidified core 320; the core soaking unit 300 is used to soak th...

Embodiment 2

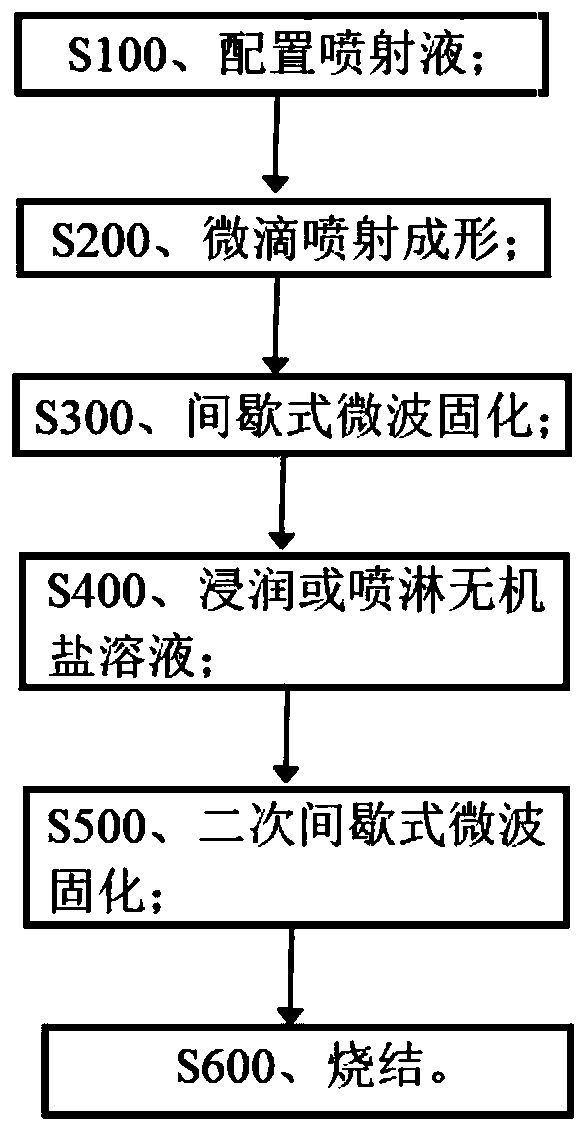

[0053] A microwave curing molding system for a water-soluble core in this implementation, its operation process is as follows:

[0054] S100, configure the spray liquid, dissolve polyethylene glycol, starch, potassium chloride, potassium hydroxide, and oxalic acid in water, and configure it into a solution with a viscosity of 3-5cps and a pH value of 7;

[0055] S200, micro-droplet injection forming, laying 100 / 140 mesh mullite sand on the lifting worktable 163, the head of the liquid spraying device 122 sprays the aqueous solution configured in S100 according to the drop path generated by the solid model of the core, and waits for the layer After the spraying of micro-droplets is completed, the lifting table 163 moves down by 0.05mm, and the subsequent dripping processes on discrete levels are completed in sequence until the dripping processes on all discrete levels are completed;

[0056] S300. Intermittent microwave curing. Take out the spray-molded core together with the c...

Embodiment 3

[0060] A microwave curing molding system for a water-soluble core in this implementation, its operation process is as follows:

[0061] S100, configure the spray liquid, dissolve polyacrylamide, polyethylene glycol solution, potassium carbonate, and potassium chloride citric acid in water, and configure it into a solution with a viscosity of 3-5 cps and a pH value of 7;

[0062] S200, micro-droplet injection forming of water-soluble core, mix 70 / 100 mesh silica sand and 100 / 140 mesh mullite sand evenly and spread them on the lifting worktable 163, the liquid spray device 122 generates the droplets according to the solid model of the core The liquid path sprays the aqueous solution configured in S100, and after the spraying of micro-droplets on this level is completed, the lifting table 163 moves down by 0.03mm, and the subsequent dripping processes on discrete levels are completed in sequence until the dripping processes on all discrete levels are completed;

[0063] S300. Int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com