RELEASE OF ClO2 GAS FROM MEDICAL DEVICE PACKAGING FILM

A packaging film and oxygen barrier technology, applied in packaging, wrapping paper, household packaging, etc., can solve problems such as timing is difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Prepare 35% by weight sodium chlorite (technical grade; 80% NaClO 2 ; Sigma-Aldrich, St.Louis, MO) in water and compounded into ExxonMobil using a 50mm co-rotating twin-screw extruder 3040 resin particles (ethylene-hexene copolymer; density = 0.900g / cm 3 ; Melt Index = 17 dg / min; ExxonMobil Chemical Company, Baytown, TX). The sodium chlorite content of the resulting resin was 7.4% by weight.

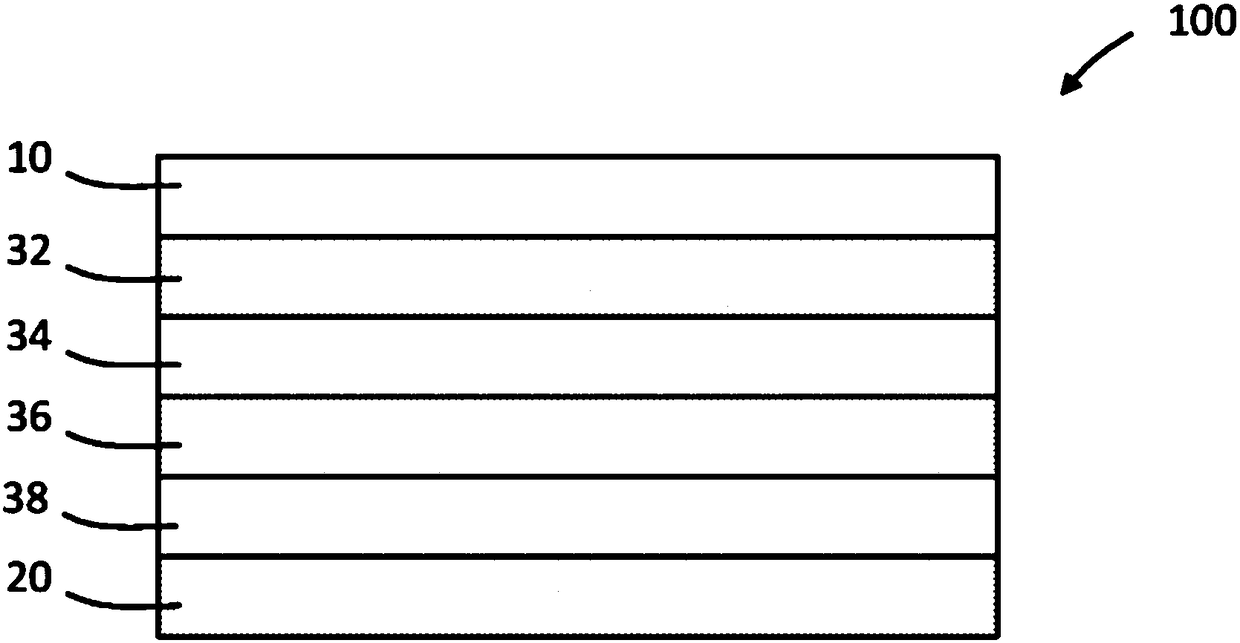

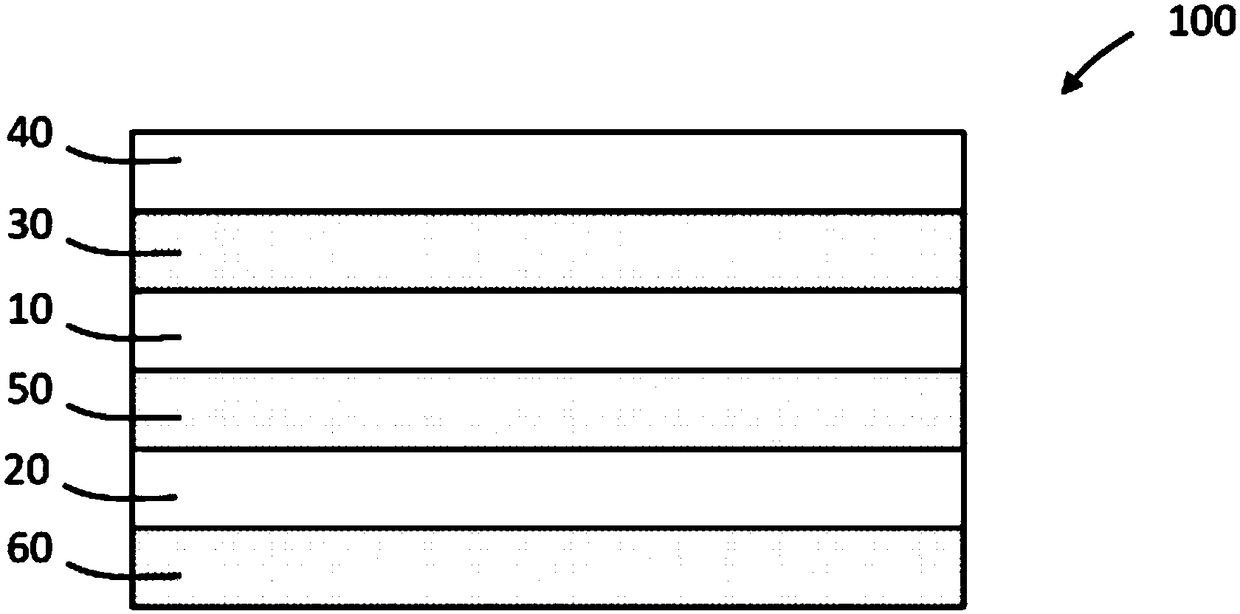

[0124] The sodium chlorite-containing resin was melt-cast into a film by using a three-layer flat-die extrusion system through a melt-extrusion process. The EVOH and LDPE layers were extruded simultaneously with the sodium chlorite-containing resin using a co-extrusion process to produce a 25 cm wide three-layer sheet such that the layers were arranged as follows: 1.5 mil LDPE / 1.5 mil EVOH / 1 mil LLDPE sodium chlorite. EVA (DuPont 3124EVA) monolayer film was also produced. These do not contain sodium chlorite.

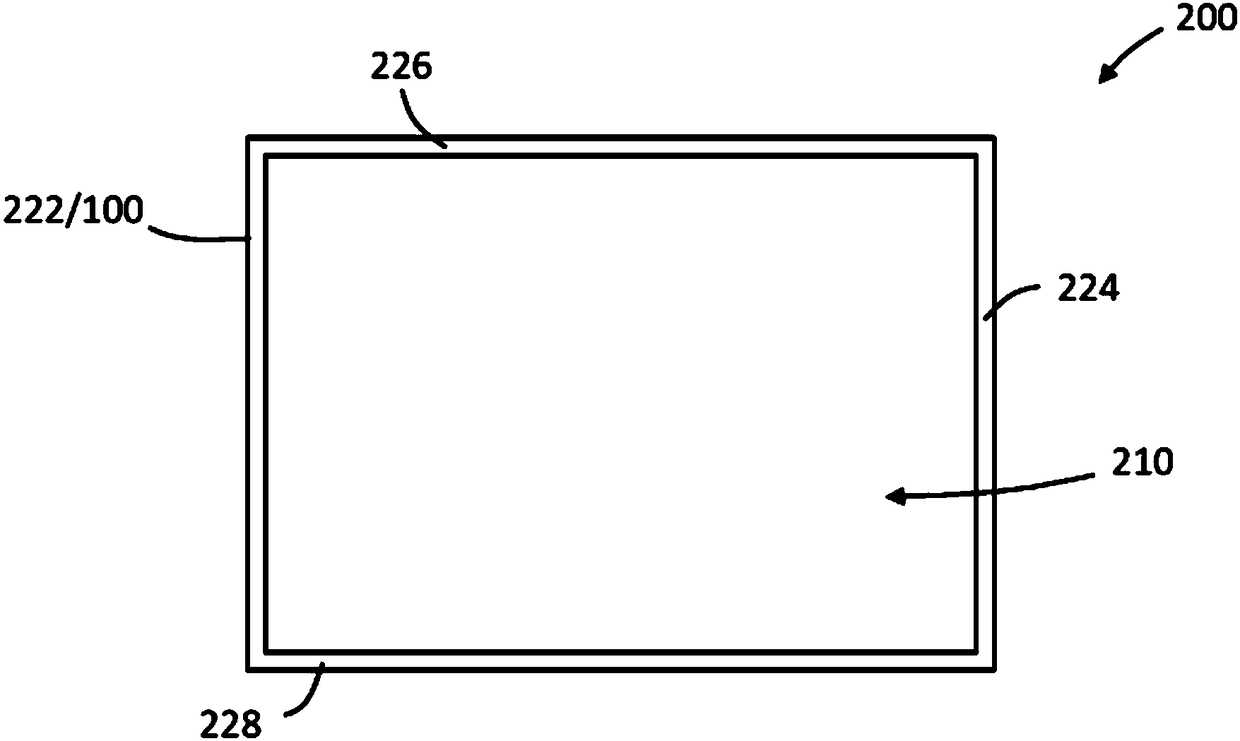

[0125] A self-sterilizing bag was made from the film by fold...

Embodiment 2

[0129]The sodium chlorite-containing resin and film were produced using the same procedure as described in Example 1 for self-sterilizing bags. The resulting film had a structure of 1.5 mil LDPE / 1.5 mil EVOH / 1.5 mil LLDPE containing sodium chlorite (16% by weight).

[0130] A self-sterilizing bag was made from the film by folding the two sides of the film sample (30 cm long, 15 cm wide) over itself and heat sealing, so that the chlorite-containing resin layer was inside. These bags were placed in a high humidity environment (35°C, 80% RH) for about 12 hours. A self-contained biological indicator (SCBI) is inserted into the pouch of interest along with a vacutainer (a small device made of rigid plastic used to take a fixed volume of blood from a patient) and heat sealed to complete the airtight package. The pouch was exposed to 254nm UV for 180 seconds. When the bag is opened, use ClO 2 Gas alarm detector to see if there is still ClO in the package 2 .

[0131] SCBI in pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com