A kind of graphene oxide-fluorine-containing piezoelectric plastic composite film and preparation method thereof

A technology of fluorine-containing piezoelectric and composite thin films, which is applied in the field of modification of fluorine-containing piezoelectric plastics, and can solve the problems that cannot be prepared on a large scale and require specific spin-coating equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a graphene oxide-fluorine-containing piezoelectric plastic composite film, which includes the following steps:

[0025] Mixing graphene oxide, water, coupling agent and amino polyethylene glycol monomethyl ether to modify the graphene oxide to obtain polyethylene glycol modified graphene oxide;

[0026] The polyethylene glycol modified graphene oxide is mixed with an organic solvent and a fluorine-containing piezoelectric plastic to obtain a mixed solution, and the mixed solution is dried to obtain a polyethylene glycol modified graphene oxide and a fluorine-containing piezoelectric plastic Mixed materials of plastics;

[0027] Under the condition of 200-220°C, the mixed material is pressed into a film to obtain a graphene oxide-fluorine-containing piezoelectric plastic composite film.

[0028] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those sk...

Embodiment 1

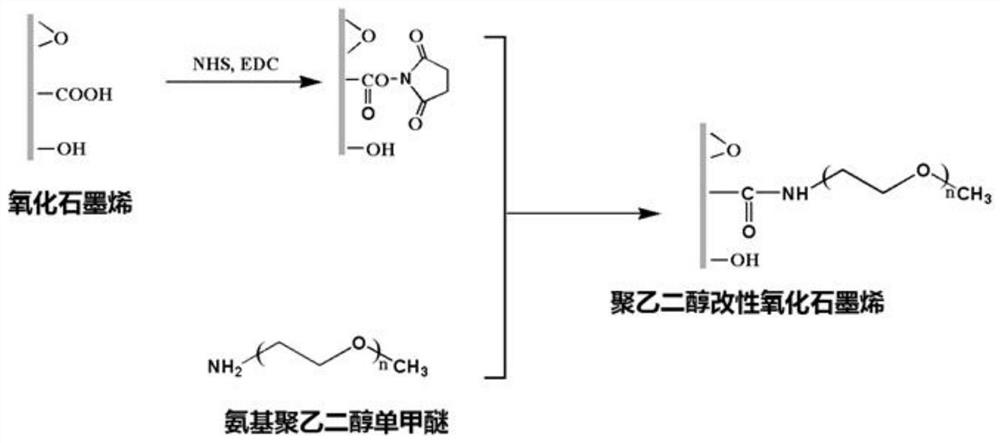

[0050] The preparation route of polyethylene glycol modified graphene oxide is as follows figure 1 Shown.

[0051] Pour 2 g of graphene oxide into 400 mL of distilled water, and ultrasonically disperse to obtain a graphene oxide dispersion;

[0052] Pour 6g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and 3g N-hydroxysuccinimide (NHS) into the graphene oxide dispersion and stir until After it is fully dissolved, pour 8g of amino polyethylene glycol monomethyl ether into it. After ultrasonic dispersion, stir at a stirring rate of 200 rpm and a temperature of 30°C for 72 hours. After the stirring is completed, use distilled water as a detergent at 10000 rpm. At the centrifugal speed, carry out centrifugal washing, centrifugal washing 8 times, each centrifugal washing time is 10min, suction filter, and dry the filtered material at 60℃ for 72 hours to obtain polyethylene glycol modified graphene oxide ;

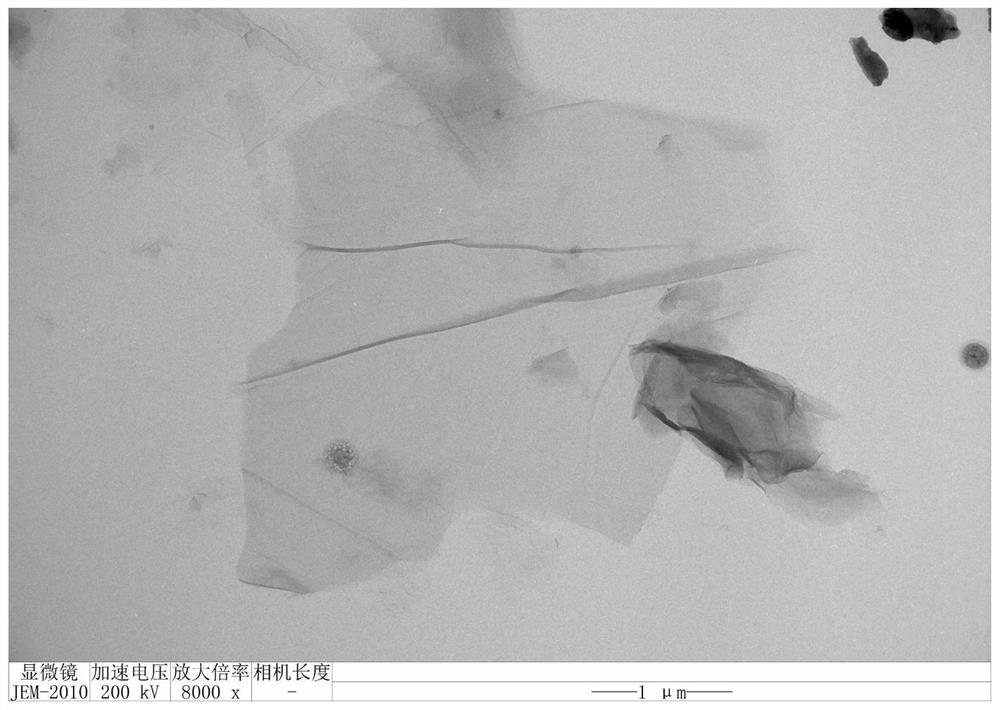

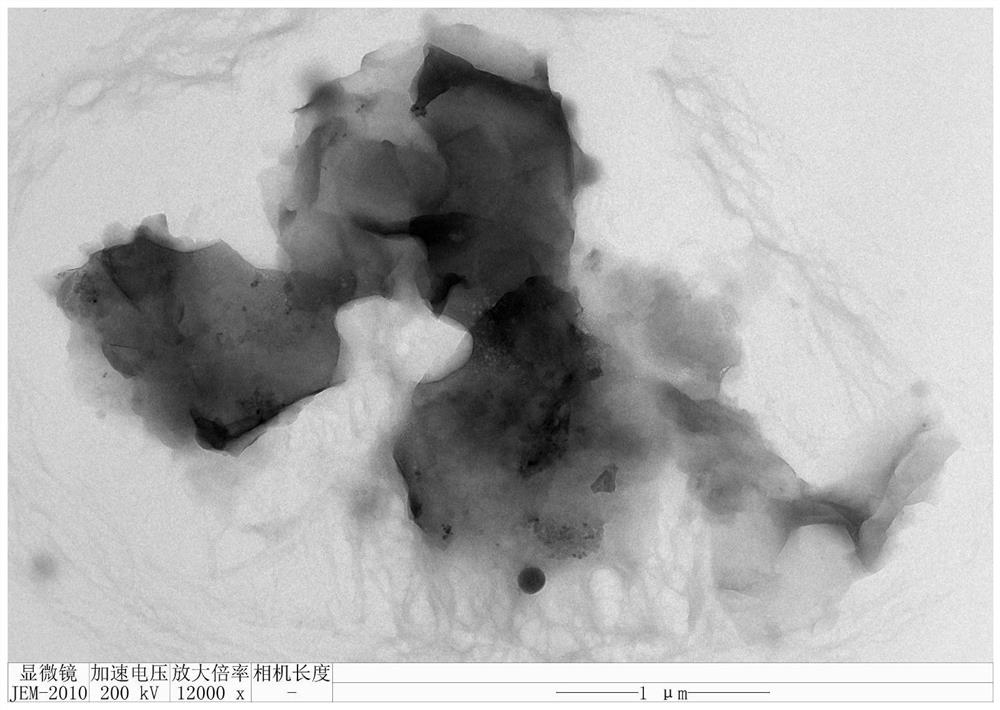

[0053] The obtained polyethylene glycol modified graphene ox...

Embodiment 2

[0061] The preparation of polyethylene glycol modified graphene oxide is as in Example 1.

[0062] Add 0.1g polyethylene glycol modified graphene oxide to 10g DMAc (dimethylacetamide) solvent, ultrasonically disperse, then add 0.9g polyvinylidene fluoride-hexafluoroisopropylene, and stir for 1.5 hours at 75℃ to form Homogeneous solution, and pour the homogeneous solution into a clean petri dish, put it in a blast oven at 75℃, dry for 72 hours, obtain polyethylene glycol modified graphene oxide and polyvinylidene fluoride-hexafluoroiso Mixed materials of propylene;

[0063] The obtained mixed material was put into two iron plates of a tablet press, and the two iron plates were clamped and put into the tablet press to be pressed into a film under the conditions of 210°C and 9 MPa to obtain a graphene oxide-fluorine-containing press Electric plastic composite film.

[0064] The graphene oxide-fluorine-containing piezoelectric plastic composite film obtained is subjected to FTIR test, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com