Preparation method for ultrafine-grained beryllium-aluminum alloy and product thereof

A technology of beryllium aluminum alloy and ultra-fine grain, which is applied in the field of preparation of ultra-fine grain beryllium aluminum alloy, can solve the problems that it is difficult to obtain uniform, fine and coarse beryllium aluminum alloy grains, and achieve the improvement of mechanical properties, elimination of segregation, and mechanical properties and tissue homogeneity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

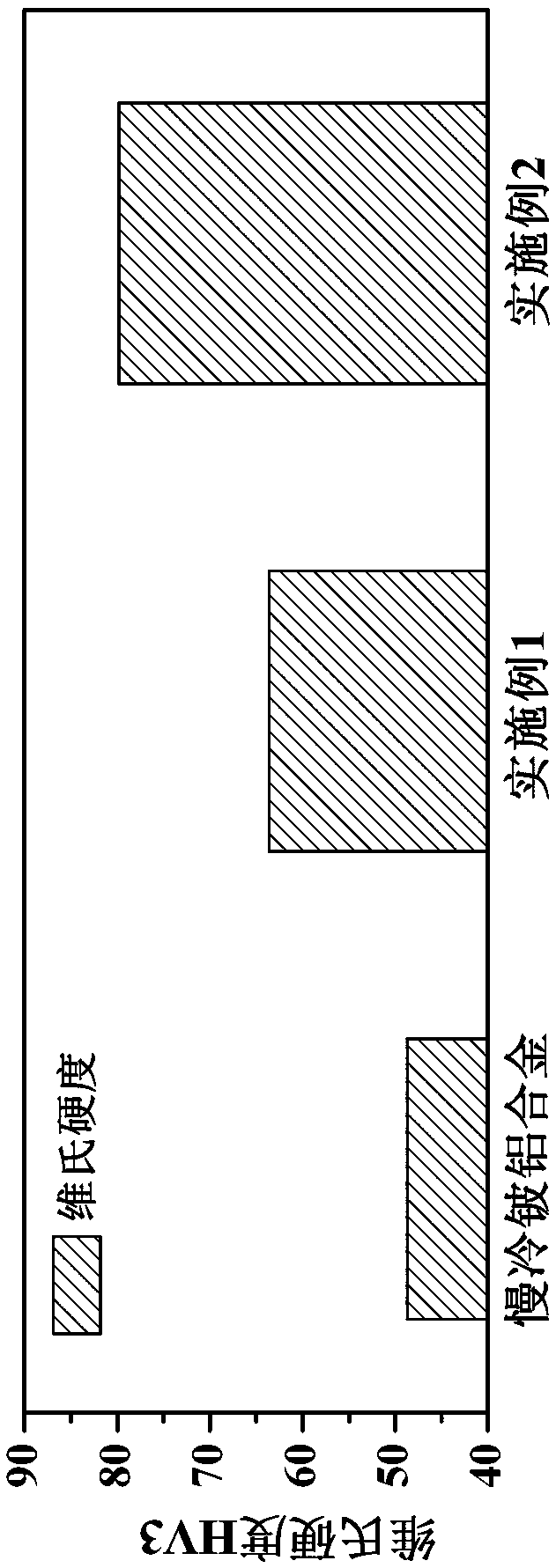

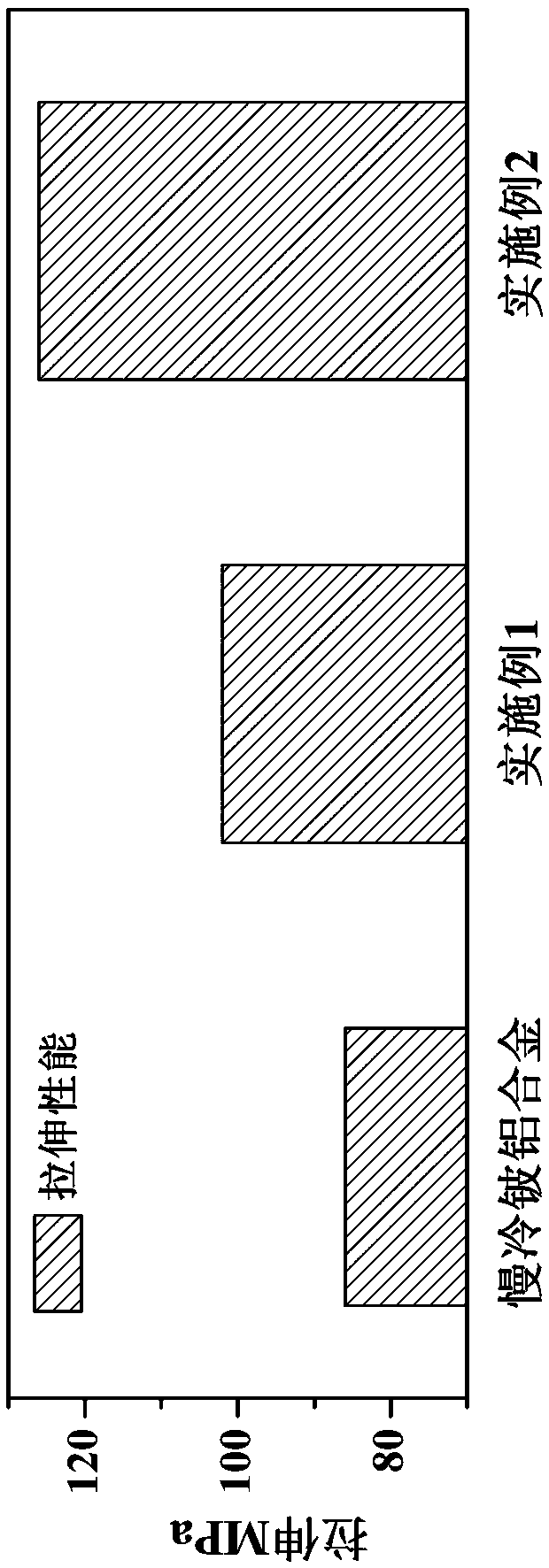

Embodiment 1

[0035] Each component was weighed according to the following mass percentages: 60wt% beryllium, 40wt% metal aluminum, set aside.

[0036] The ultra-fine-grained beryllium-aluminum alloy is prepared according to the following steps, specifically as follows.

[0037] (1) Pre-alloying of beryllium aluminum alloy

[0038] Put the weighed metal beryllium and aluminum raw materials into the hemispherical water-cooled copper mold crucible of the vacuum arc melting furnace, wherein the aluminum material is placed in the lower part of the crucible, and the beryllium material is placed in the upper part of the crucible. The casting process is as follows: First, the furnace body is evacuated to 5×10 -3 ~3×10 -3 Pa, keep it for 30 minutes, fill it with high-purity argon to 0.3~0.4 MPa, smelting current 410±10 amps, smelting time 5±0.5 minutes, repeat smelting 6~8 times, after cooling, obtain pre-alloyed beryllium aluminum alloy ingot.

[0039] (2) After the pre-alloyed beryllium alumi...

Embodiment 2

[0042] Each component was weighed according to the following mass percentages: 62wt% beryllium, 38wt% metal aluminum, set aside.

[0043] The ultra-fine-grained beryllium-aluminum alloy is prepared according to the following steps, specifically as follows.

[0044] (1) Pre-alloying of beryllium aluminum alloy

[0045] Put the weighed metal beryllium and aluminum raw materials into the alumina ceramic crucible of the vacuum induction melting furnace, wherein the aluminum material is placed on the upper part of the crucible, and the beryllium material is placed on the lower part of the crucible. The casting process is: the vacuum degree is controlled at 5×10 -2 ~1×10 -2 Pa, the melting temperature is 1365±15 degrees Celsius, the melting time is 44±2 minutes, the holding temperature is 1340±15 degrees Celsius, the holding time is 2.5±0.5 minutes, and the pouring temperature is 1310±10 degrees Celsius. The smelted melt is poured into a mold to obtain a pre-alloyed beryllium alu...

Embodiment 3

[0049] Each component was weighed according to the following mass percentages: 78wt% beryllium, 22wt% metal aluminum, set aside.

[0050] The ultra-fine-grained beryllium-aluminum alloy is prepared according to the following steps, specifically as follows.

[0051] (1) Pre-alloying of beryllium aluminum alloy

[0052] Put the weighed metal beryllium and aluminum raw materials into the zirconia ceramic crucible of the vacuum induction melting furnace, wherein the aluminum material is placed in the lower part of the crucible, and the beryllium material is placed in the upper part of the crucible. The casting process is: the vacuum degree is controlled at 2.1×10 -2 ~8.5×10 -3 Pa, the melting temperature is 1375±15 degrees Celsius, the melting time is 45±3 minutes, the holding temperature is 1365±10 degrees Celsius, the holding time is 3.5±0.5 minutes, and the pouring temperature is 1300±5 degrees Celsius. The smelted melt is poured into a mold to obtain a pre-alloyed beryllium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com