Method for peeling nickel-cobalt-manganese ternary lithium battery positive current collector based on supercutical fluid and reactor

A nickel-cobalt-manganese ternary lithium and supercritical fluid technology, which is applied in the field of waste battery recycling, can solve the problems of being unfriendly to the environment, cumbersome stripping methods, etc., and achieve the effects of good stripping effect, low cost and environmental protection in the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

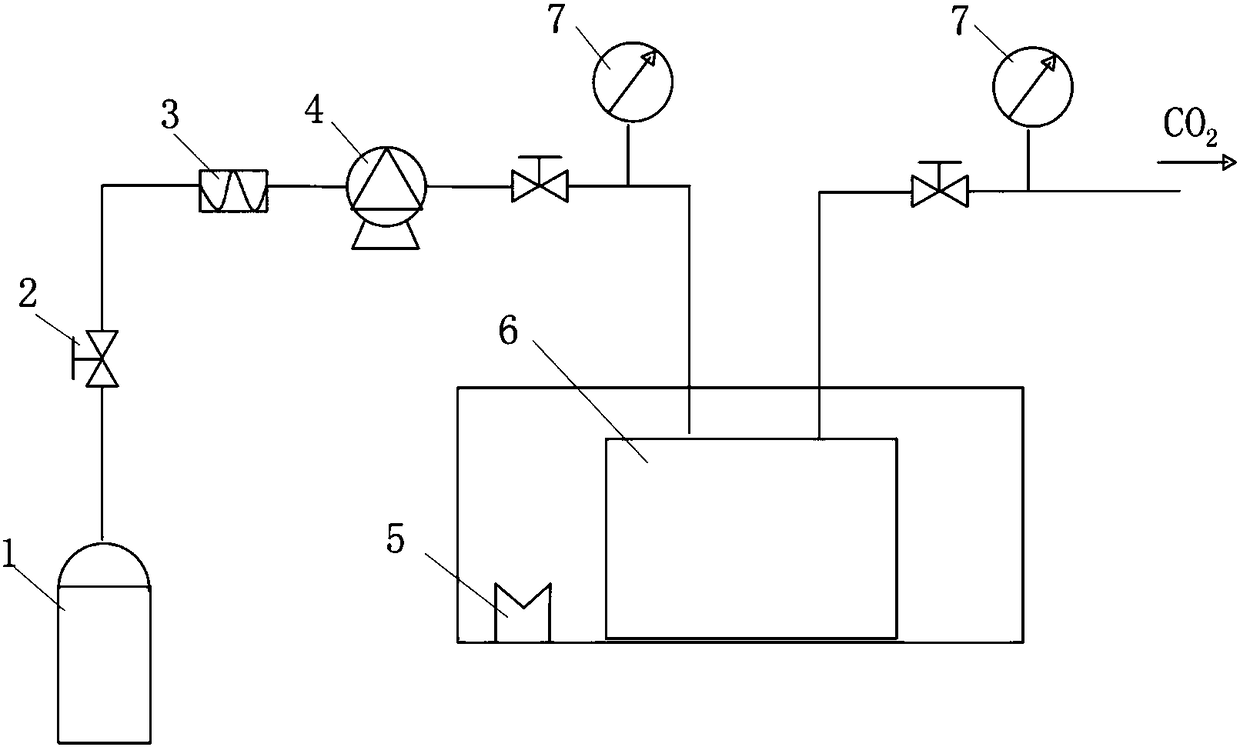

Method used

Image

Examples

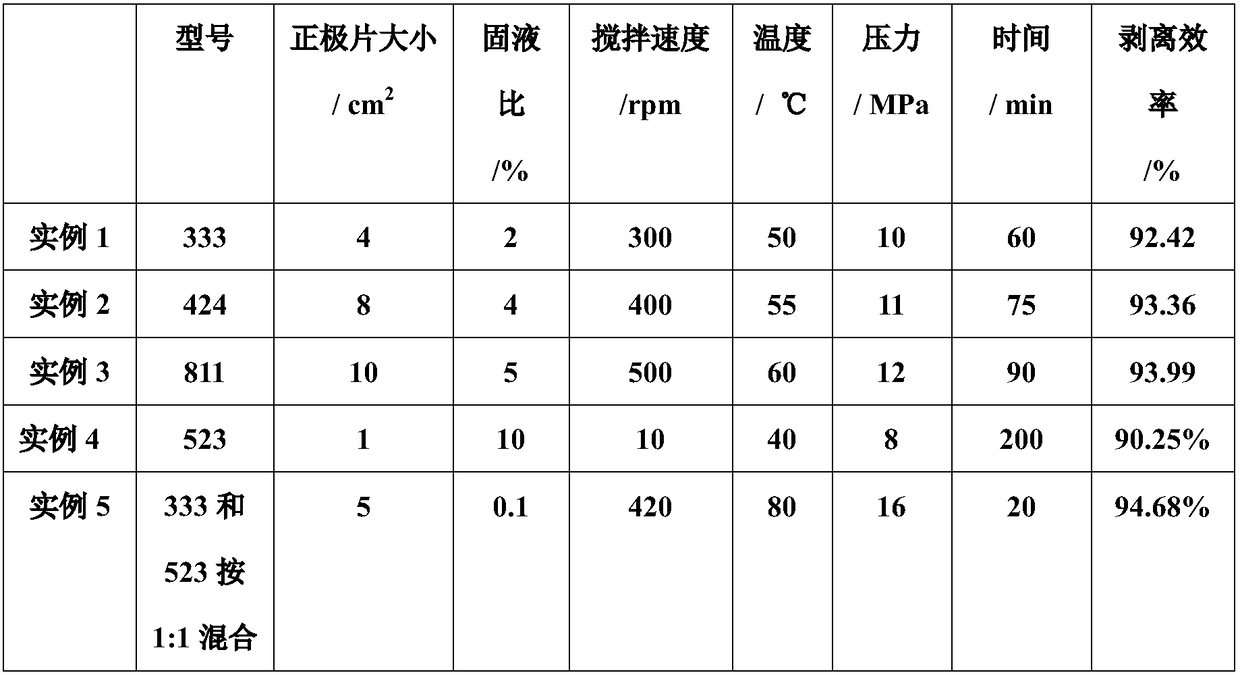

Embodiment 1

[0018] After fully discharging the 333-type nickel-cobalt-manganese ternary lithium battery, manually disassemble the battery, sort out the positive electrode material, and break it to 4cm 2 After the size, put it in the reaction kettle of the reactor, add an appropriate amount of water according to the solid-to-liquid ratio of 2%, and control the mechanical stirring speed to be 300rpm, then put the supercritical fluid into the reaction kettle through a high-pressure pump to control the speed of the stripping process. The temperature is 50°C, the stripping pressure is 10MPa, and the stripping time is 60min to dissolve the organic components in the positive electrode material of the nickel-cobalt-manganese ternary lithium-ion battery, and strip the positive electrode current collector. The mass fraction of the positive current collector in the positive electrode material was measured by the alkali dissolution method, and the stripping rate was calculated to be 92.42% according t...

Embodiment 2

[0020] After fully discharging the 424-type nickel-cobalt-manganese ternary lithium battery, manually disassemble the battery, sort out the positive electrode material, and crush it to 8cm 2 After the size, put it into the reactor of the reactor, add an appropriate amount of ethanol according to the solid-to-liquid ratio of 4%, and control the mechanical stirring speed to be 400rpm, then put the supercritical fluid into the reactor by a high-pressure pump to control the speed of the stripping process. The temperature is 55°C, the peeling pressure is 11MPa, and the peeling time is 75min, to dissolve the organic components in the positive electrode material of the nickel-cobalt-manganese ternary lithium-ion battery, and peel off the positive electrode current collector. The mass fraction of the positive current collector in the positive electrode material was measured by the alkali solution method, and the stripping rate was calculated to be 93.36% according to the mass change of...

Embodiment 3

[0022] After fully discharging the 811-type nickel-cobalt-manganese ternary lithium battery, manually disassemble the battery, sort out the positive electrode material, and crush it to 10cm 2 After the size, put it in the reaction kettle of the reactor, add an appropriate amount of acetone according to the solid-to-liquid ratio of 5%, and control the mechanical stirring speed to 500rpm, then put the supercritical fluid into the reaction kettle through a high-pressure pump to control the speed of the stripping process. The temperature is 60°C, the peeling pressure is 12MPa, and the peeling time is 90min, to dissolve the organic components in the positive electrode material of the nickel-cobalt-manganese ternary lithium-ion battery, and peel off the positive electrode current collector. The mass fraction of the positive current collector in the positive electrode material was measured by the alkali dissolution method, and the stripping rate was calculated to be 93.99% according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com