Device and method for preparing hydrogen chloride gas through continuous method full hydrochloric acid analysis

A technology for the analysis of hydrogen chloride gas and hydrochloric acid, which is applied in the field of continuous hydrochloric acid full analysis to produce hydrogen chloride gas, can solve the problems of high hydrogen chloride content, insufficient heat and mass transfer, decreased heat transfer efficiency, etc., and achieves low impurity content requirements and saves money. The effect of heating steam consumption and low cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited thereto.

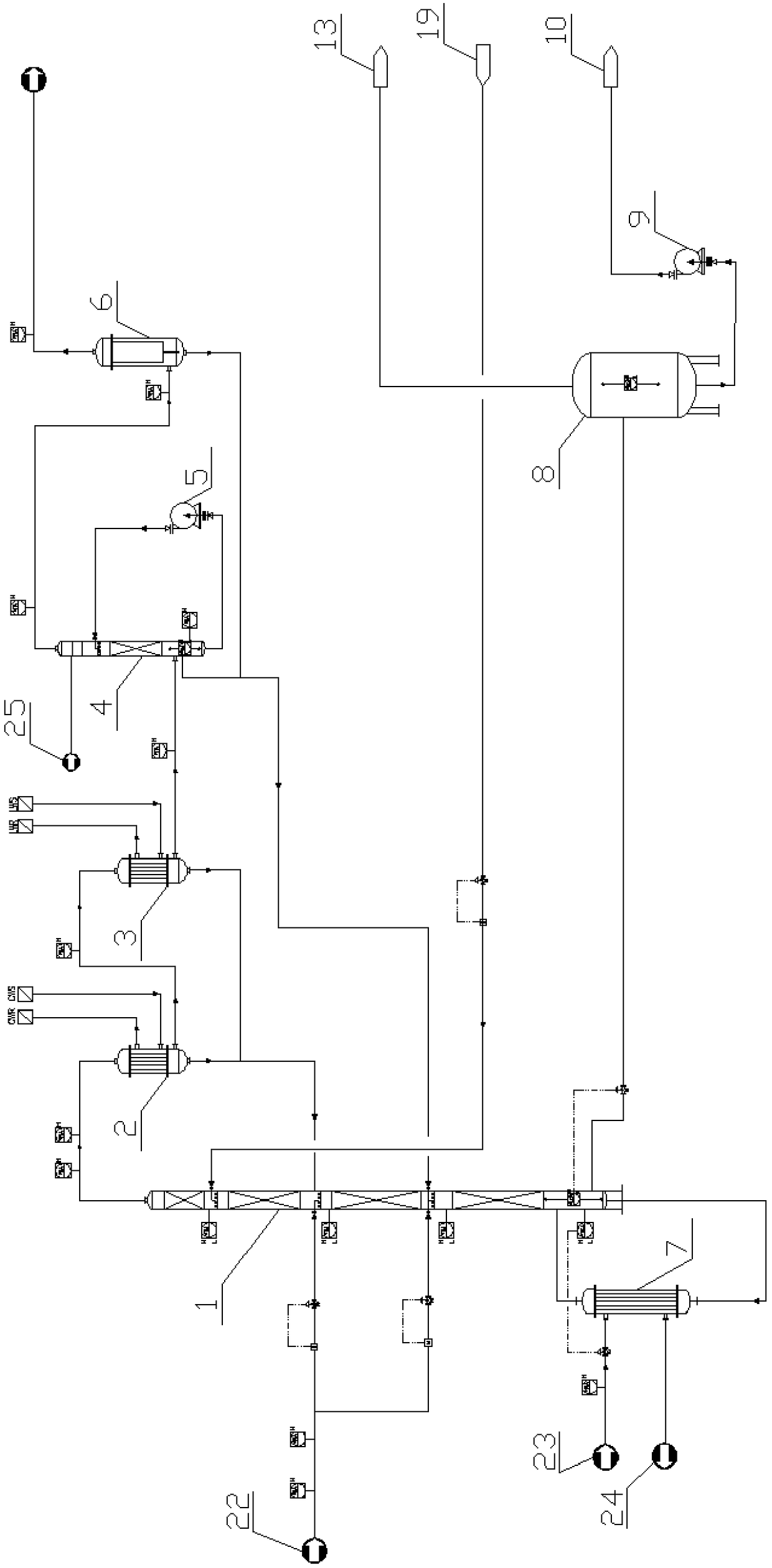

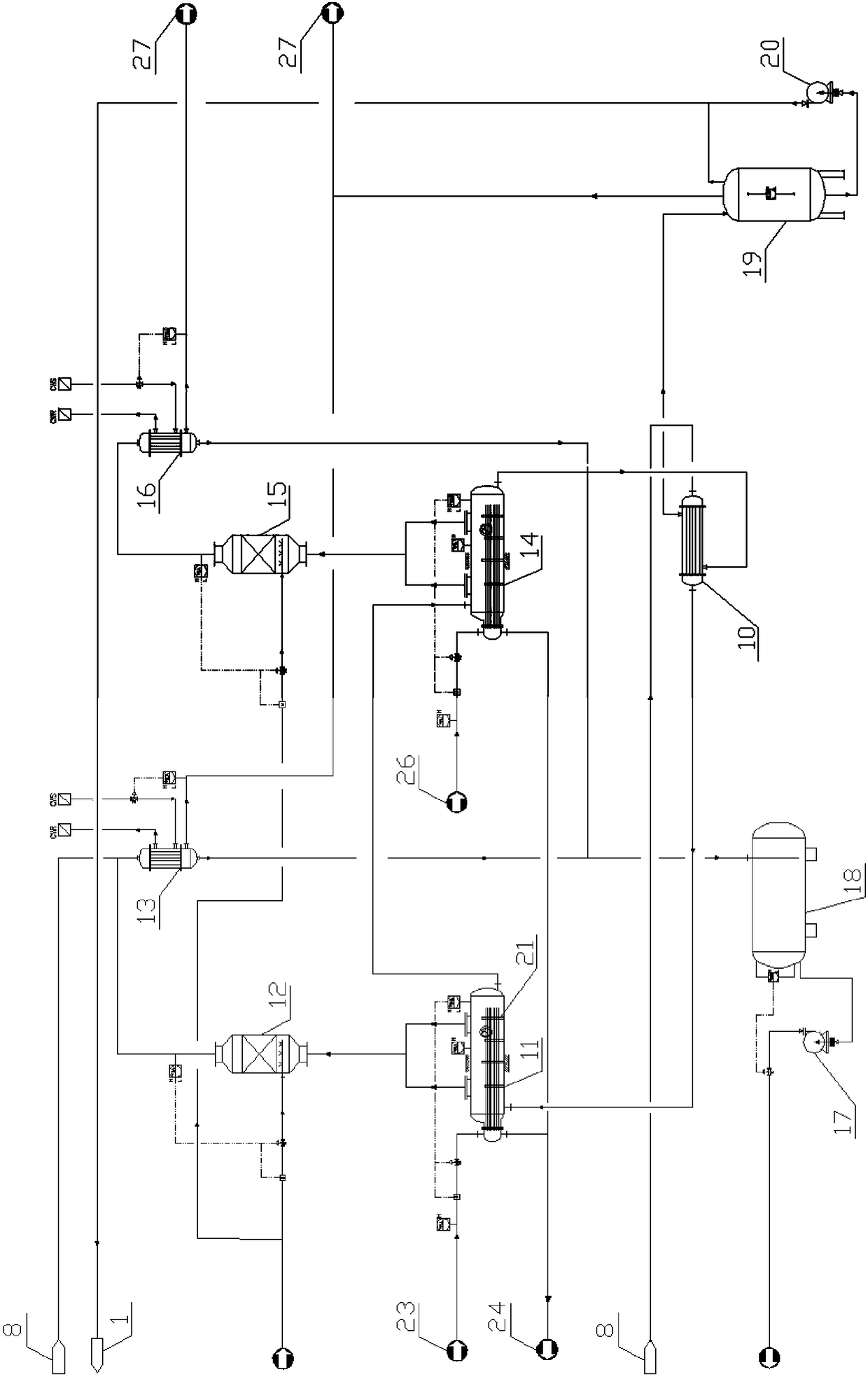

[0039] refer to figure 1 , figure 2 , a device for producing hydrogen chloride gas by continuous hydrochloric acid full analysis, the device includes an analysis system and a dilute sulfuric acid vacuum concentration system, and the analysis system includes a hydrochloric acid analysis tower 1, a primary hydrogen chloride cooler 2, and a secondary hydrogen chloride cooler 3, concentrated sulfuric acid drying tower 4, acid mist separator 6, dilute sulfuric acid reboiler 7, described dilute sulfuric acid vacuum concentration system includes dilute sulfuric acid flash tank 8, acid-acid heat exchanger 10, primary sulfuric acid concentration tank 11, Secondary sulfuric acid concentration tank 14, primary scrubber 12, primary steam condenser 13, secondary scrubber 15, seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com