Preparation method of fluorinated graphene nanobelt

A fluorinated graphene and nanoribbon technology, applied in the field of graphene, can solve the problems of difficult industrialization promotion, complex process, high energy consumption, and achieve the effects of good application prospect, simple operation and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of fluorinated graphene nanobelt, comprises the following steps:

[0024] The anhydrous carbon nanotubes are fluorinated in a fluorine gas atmosphere under the conditions of -0.07-0 MPa and 280-450° C. to obtain fluorinated graphene nanobelts.

[0025] The present invention can use single-wall carbon nanotubes, double-wall carbon nanotubes or multi-wall carbon nanotubes as carbon nanotube raw materials.

[0026] In order to ensure the smooth progress of the fluorination process, the carbon nanotubes must be anhydrous. The water removal mode of the anhydrous carbon nanotubes is preferably:

[0027] Put the carbon nanotubes and desiccant into a vacuum drying oven, and dry them under vacuum at 80-120°C.

[0028] The drying time is preferably 4-8 hours.

[0029] The desiccant is preferably one or more of anhydrous phosphorus pentoxide, molecular sieve and activated carbon.

[0030] Preferably in the present invention, ...

Embodiment 1

[0043] (1) Put 10 mg of single-walled carbon nanotubes into a tube furnace and pass H 2 , purified at 500°C for 5h;

[0044] (2) Put the purified 10 mg single-walled carbon nanotubes into a vacuum drying oven at 100°C, and put anhydrous phosphorus pentoxide in the bottom of the vacuum drying oven, take it out and seal it after 4 hours, and set aside;

[0045] (3) Put 10 mg of dry single-walled carbon nanotubes obtained in (2) into the reactor to evacuate to a vacuum. After the reactor is heated up to a reaction temperature of 300° C., keep it warm for 240 minutes, and then evacuate to a vacuum and feed 20% fluorine gas Mixed gas with nitrogen to -0.07Mpa, react for 4h;

[0046] (4) The product obtained in (3) was placed in a vacuum oven and dried for 10 h to obtain 8.3 mg of fluorinated graphene nanoribbons with a fluorocarbon ratio of 0.97.

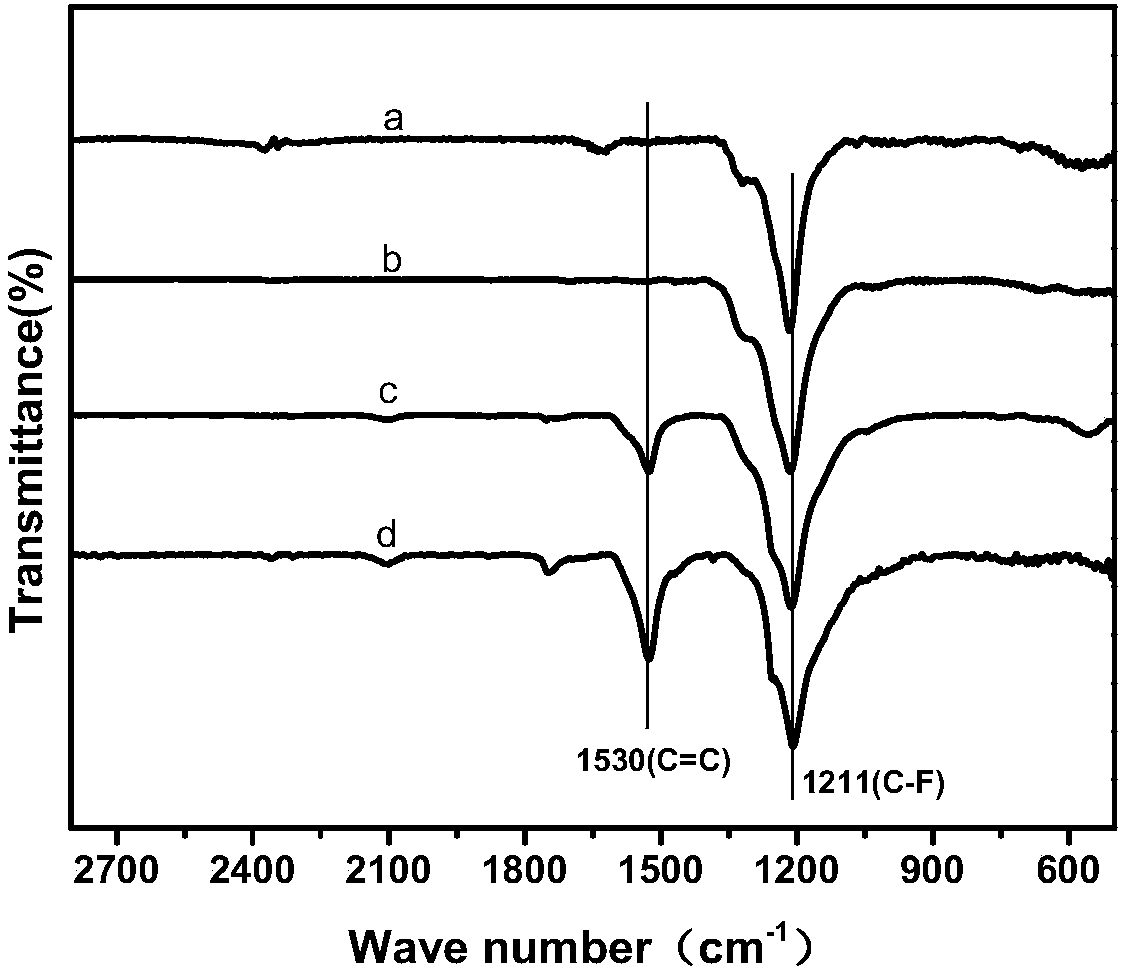

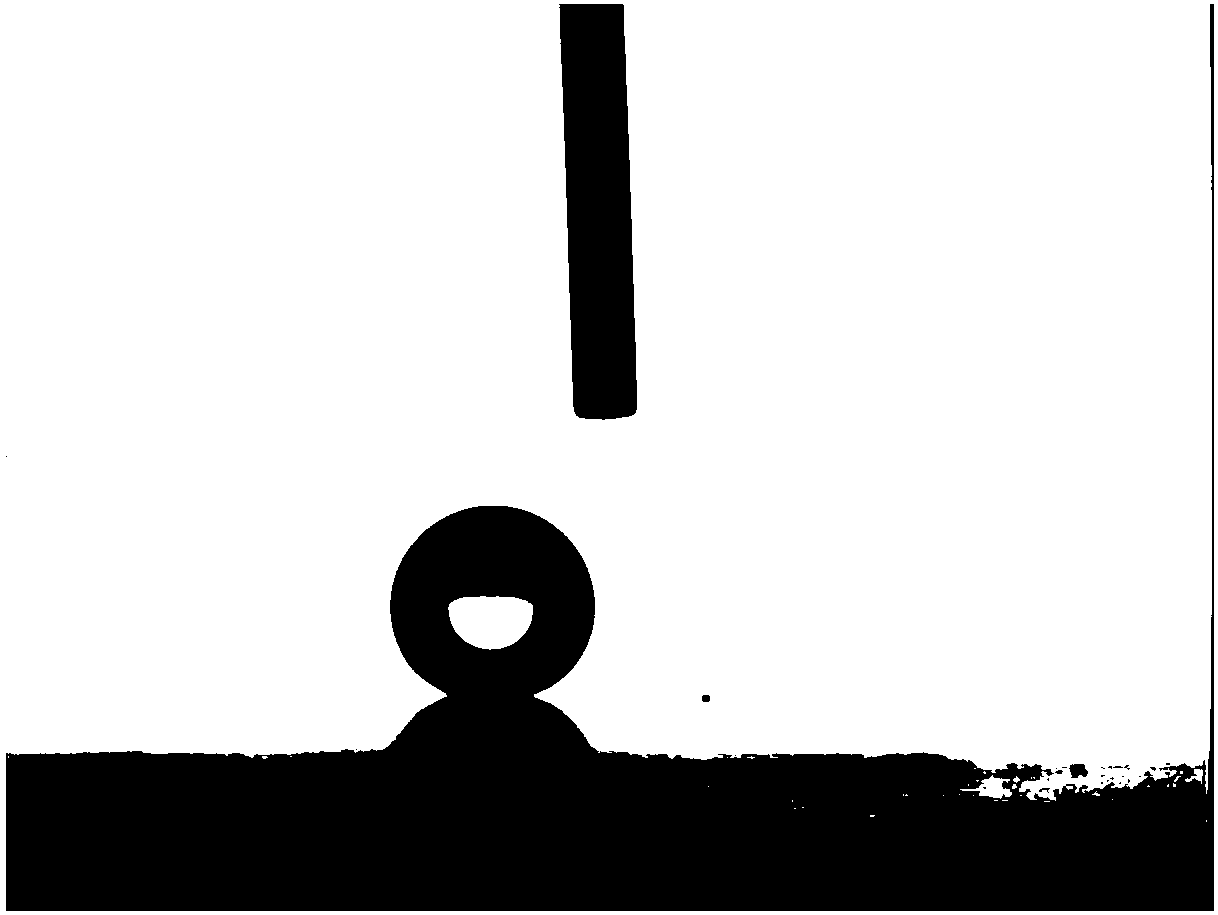

[0047] The microstructure of the prepared fluorinated graphene nanoribbons was characterized by transmission electron microscopy, fi...

Embodiment 2

[0052] (1) Put 50 mg of single-walled carbon nanotubes into a tube furnace and pass H 2 , and purify at 500° C. for 5 hours.

[0053] (2) Put 50 mg of purified single-walled carbon nanotubes into a vacuum drying oven at 90°C, and put anhydrous phosphorus pentoxide in the bottom of the vacuum drying oven, take it out and seal it after 6 hours, and set aside;

[0054] (3) Put 50 mg of dry single-walled carbon nanotubes obtained in (2) into the reactor to evacuate to a vacuum. After the reactor is heated up to a reaction temperature of 320° C., keep it warm for 240 minutes, and then evacuate to a vacuum and feed 20% fluorine gas Mixed gas with nitrogen to 0Mpa, react for 4h;

[0055](4) The product obtained in (3) was placed in a vacuum oven and dried for 10 h to obtain 42.6 mg of fluorinated graphene nanobelts with a fluorocarbon ratio of 1.08.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com