Method for treating wastewater

A technology for treating wastewater and wastewater, applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as foul smell, environmental impact, health impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

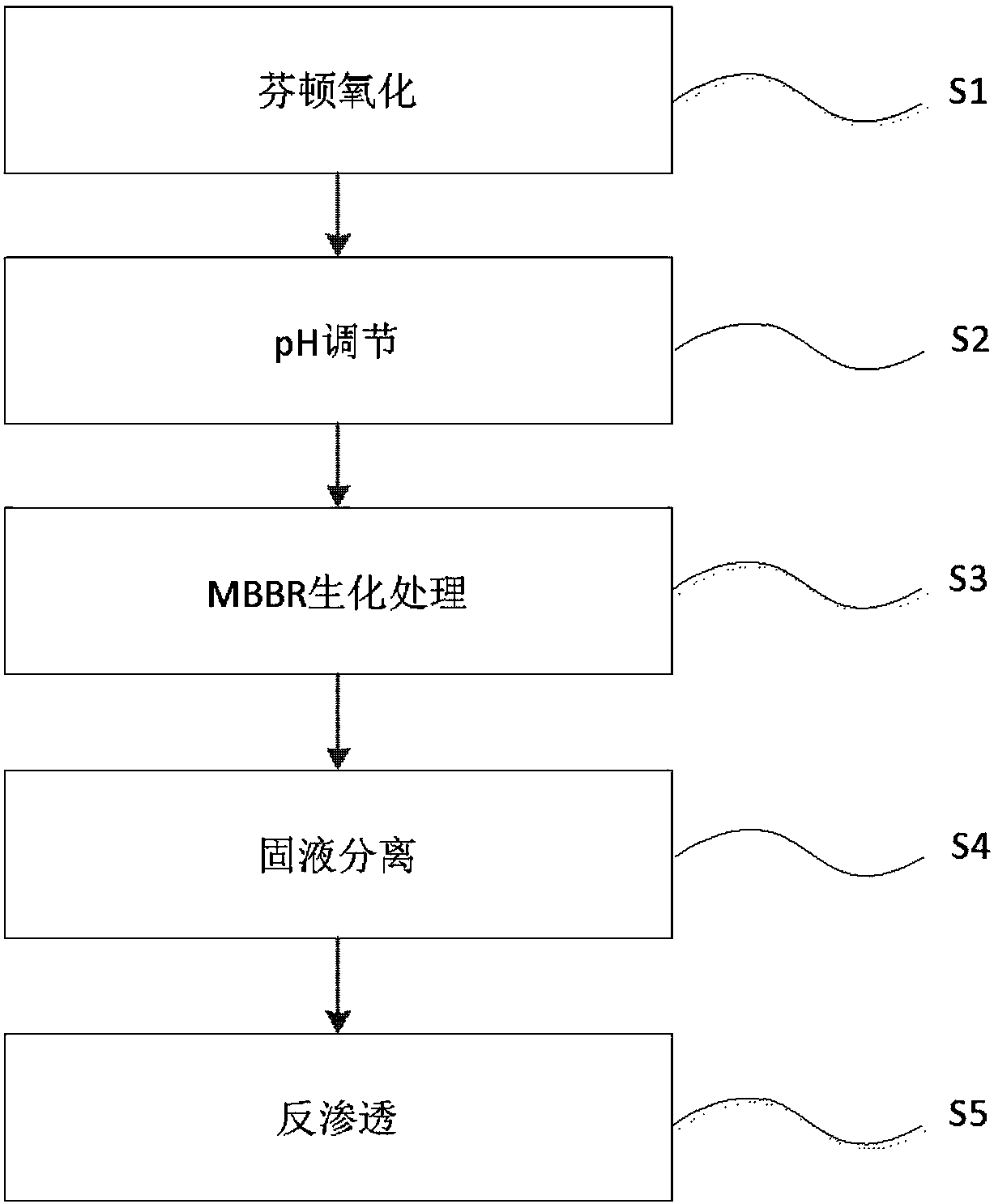

Method used

Image

Examples

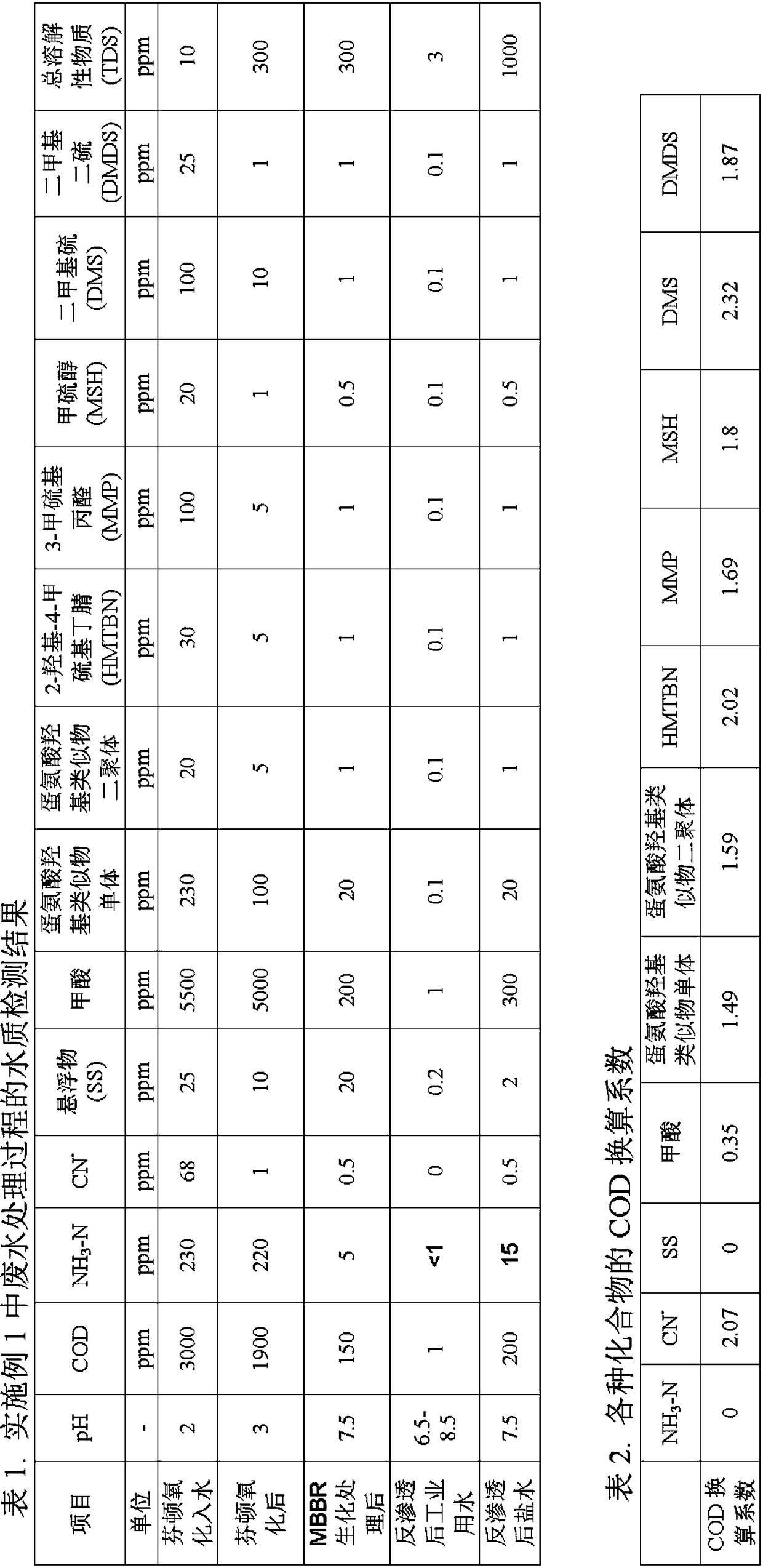

Embodiment 1

[0087] The waste water produced in the production process of methionine hydroxy analogues is transported to a crystallization tank for evaporative crystallization at 57-60° C. to obtain 30-50% by weight of ammonium sulfate crystals, and the crystallized waste water is transported to a storage tank for storage and stirring.

[0088] The wastewater was transported to the Fenton heterogeneous catalytic reactor, and ferrous sulfate (FeSO 4 ·7H 2 O, 20% solution) and hydrogen peroxide (H 2 o 2 , 27.5% solution) mixed solution, Fe 2+ The molar ratio of hydrogen peroxide and hydrogen peroxide is about 1:7, and the molar ratio of hydrogen peroxide and COD in waste water is about 2:1, and the Fenton oxidation reaction is carried out at about 35-40°C for 100 minutes to remove about 35% of COD.

[0089] Send the waste water after Fenton oxidation to the neutralization tank, add alkali (30% sodium hydroxide solution) and adjust the pH to 6-8.

[0090] The neutralized wastewater is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com