Preparation method of diethyltoluenediamine

A technology of diethyltoluenediamine and triethylaluminum, which is used in the preparation of amino compounds from amines, chemical instruments and methods, and purification/separation of amino compounds, etc. low rate and other problems, to achieve mild reaction conditions, lower production costs, and good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of diethyltoluenediamine, comprises the following steps:

[0020] Carrying out a complex reaction between m-toluenediamine and triethylaluminum to obtain a complex material containing an aluminum complex; the temperature of the complex reaction is 150-160° C., and the pressure is 0.4-0.6 MPa;

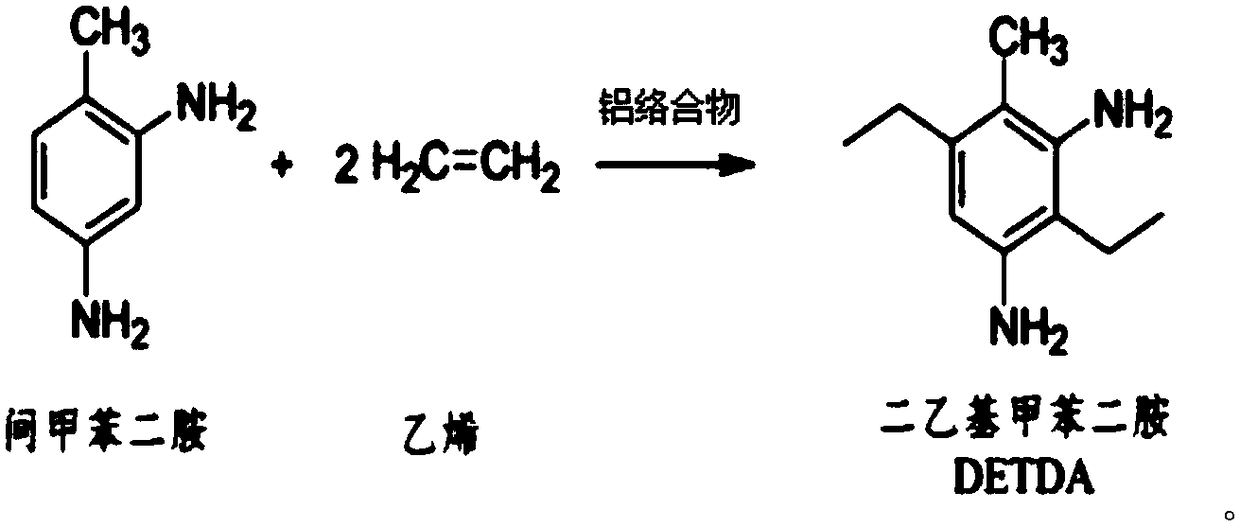

[0021] Alkylation reaction is carried out between the complex material containing aluminum complex and ethylene to obtain diethyltoluenediamine; the temperature of the alkylation reaction is 300-310° C., and the pressure is 4.6-5.0 MPa.

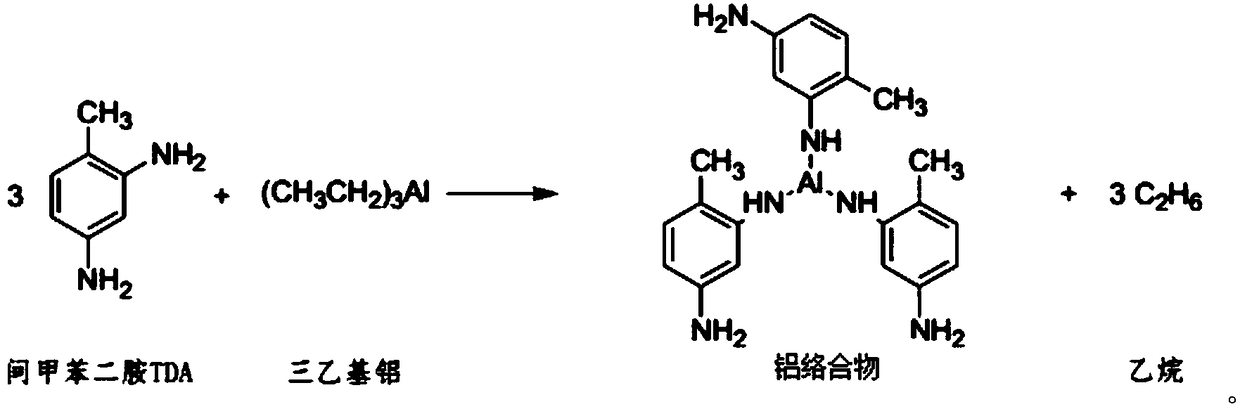

[0022] In the present invention, m-toluenediamine (TDA) and triethylaluminum are subjected to a complex reaction to obtain a complex material containing an aluminum complex; the temperature of the complex reaction is 150-160° C., and the pressure is 0.4-0.6 MPa . In the present invention, the reaction equation of described complexation reaction is specifically as follows:

[0023]

[0024]...

Embodiment 1

[0046] Put m-toluenediamine (2000kg) and triethylaluminum (35kg) in an evaporator, and under the protection of nitrogen, carry out complexation reaction at 160°C and 0.5MPa for 1.5h to obtain a complex materials;

[0047] Pump the complex material containing aluminum complex into the synthesis kettle, pass through ethylene (460kg), and carry out the alkylation reaction at 310°C and 4.6MPa for 6h under the protection of nitrogen;

[0048] Using the pressure of the synthesis tank, press the remaining ethylene in the synthesis tank after the alkylation reaction is completed into the ethylene recovery tank, and then turn on the membrane press to press the recovered ethylene into the synthesis tank for use; control the vacuum degree of the evaporation tank to ≤ -0.098MPa, the alkylation material obtained after the completion of the alkylation reaction is sucked into the evaporator, and the first vacuum distillation is carried out at 140°C. The distilled fraction is crude diethyltol...

Embodiment 2

[0053] Put m-toluenediamine (2t) and triethylaluminum (40kg) in an evaporator, and under the protection of nitrogen, carry out complexation reaction at 150°C and 0.6MPa for 2 hours to obtain complexed materials containing aluminum complexes ;

[0054] The complex material containing the aluminum complex is pumped into the synthesis kettle, and ethylene (480kg) is introduced, and under the protection of nitrogen, the alkylation reaction is carried out at 300°C and 5.0MPa for 7h, and then according to the method of Example 1 The step is post-treated to obtain the finished product of diethyltoluenediamine.

[0055] The yield of the final diethyltoluenediamine finished product is about 92%, and the purity is about 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com