Green fluorescent carbon quantum dot, and preparation method and application thereof

A green fluorescence, carbon quantum dot technology, applied in fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve problems such as poor stability, achieve low cost, improve dispersion and uniformity, and reduce by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

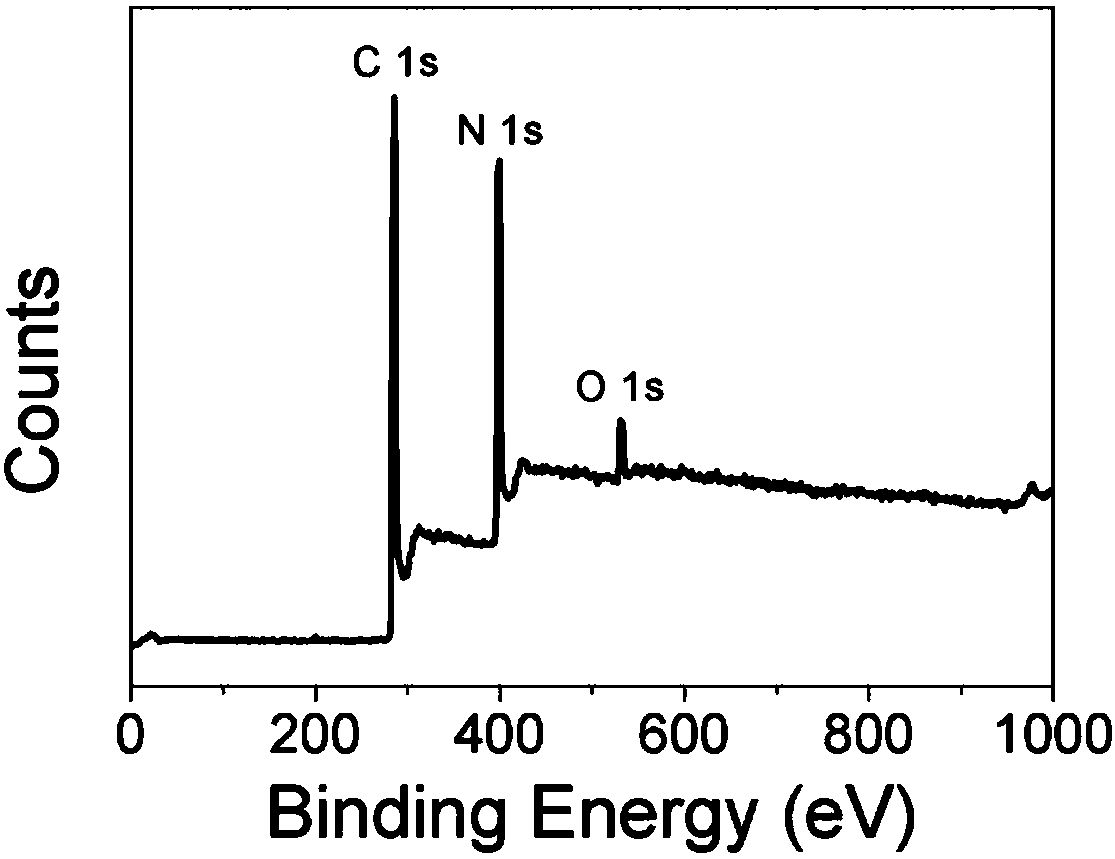

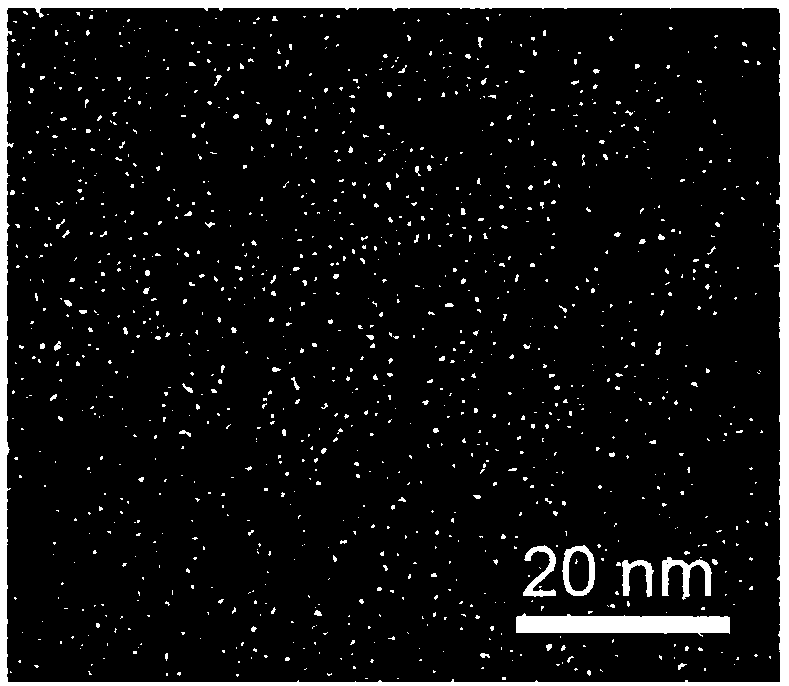

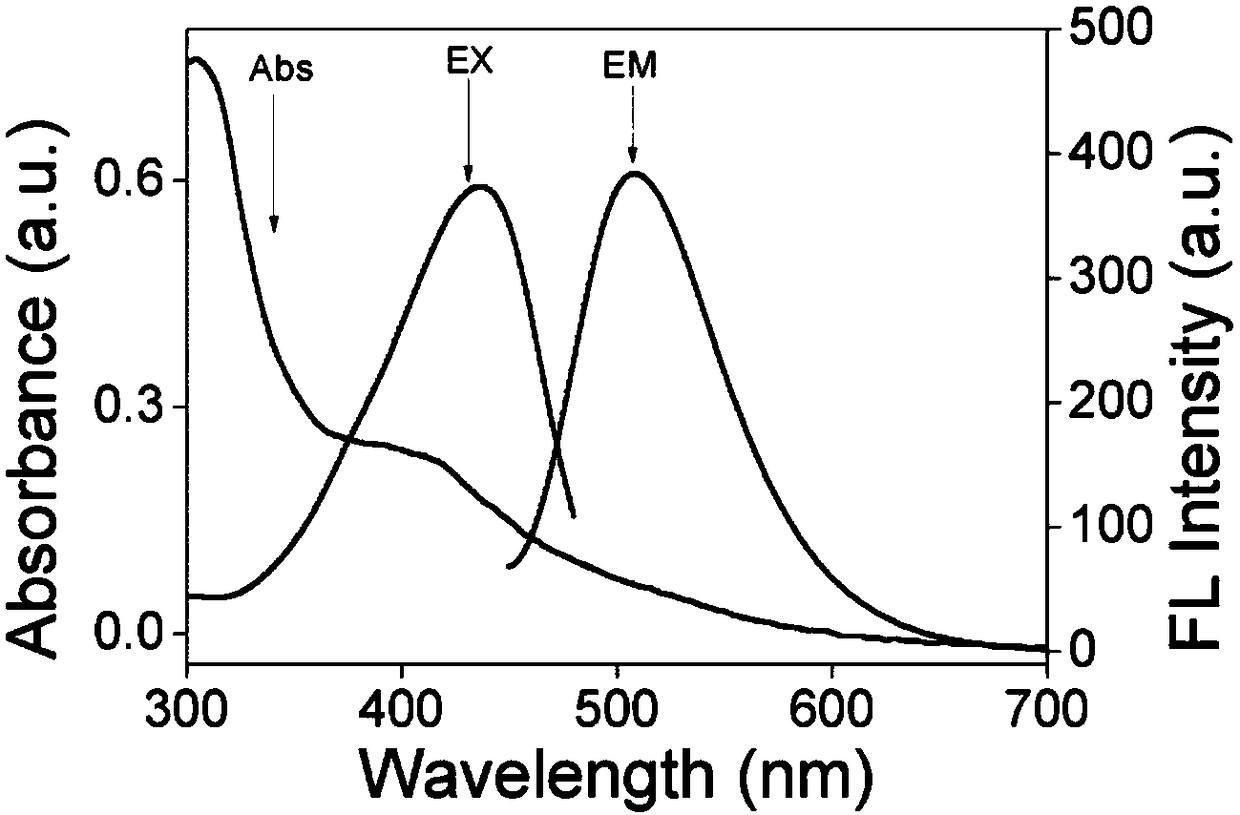

[0039] This embodiment provides a method for preparing green fluorescent carbon quantum dots, specifically:

[0040] Weigh 0.2g of 2,3-diaminopyridine and dissolve it in 20mL of N,N-dimethylformamide, then stir evenly, transfer the mixed solution into a 50mL stainless steel reaction kettle lined with polytetrafluoroethylene, and tighten the lid , and reacted at 180°C for 10 hours. The reactor was naturally cooled to room temperature to obtain an aqueous solution of green fluorescent carbon quantum dots. The solution was then centrifuged at 10,000 rpm for 15 minutes to remove large solid precipitates. The liquid was transferred into a 1000Da molecular weight dialysis bag for dialysis for 72 hours, and the liquid in the dialysis bag was collected. The collected inner liquid is freeze-dried repeatedly to obtain solid powder, which is the green fluorescent carbon quantum dot. With rhodamine 6G as reference material, based on the formula QYS=QYST (I S / I ST )(A ST / A S )(η ...

Embodiment 2

[0043] This embodiment provides a method for preparing green fluorescent carbon quantum dots, specifically:

[0044] Weigh 0.2g of 2,3-diaminopyridine and dissolve it in 20mL of acetone, then stir evenly, transfer the mixed solution into a 50mL stainless steel reaction kettle with a polytetrafluoroethylene liner, tighten the lid of the kettle, and react at 190°C for 7 Hour. The reactor was naturally cooled to room temperature to obtain an aqueous solution of green fluorescent carbon quantum dots. The solution was then centrifuged at 10,000 rpm for 15 minutes to remove large solid precipitates. The liquid was transferred into a dialysis bag with a molecular weight of 800Da for dialysis for 96 hours, and the liquid in the dialysis bag was collected. The collected inner liquid is freeze-dried repeatedly to obtain solid powder, which is the green fluorescent carbon quantum dot. Taking rhodamine 6G as a reference substance, the fluorescence quantum yield of the carbon quantum do...

Embodiment 3

[0046] This embodiment provides a method for preparing green fluorescent carbon quantum dots, specifically:

[0047] Weigh 0.2g of 2,3-diaminopyridine and dissolve it in 20mL of ethyl acetate, then stir evenly, transfer the mixed solution into a 50mL stainless steel reaction kettle lined with polytetrafluoroethylene, tighten the lid of the kettle, at 170°C React for 11 hours. The reactor was naturally cooled to room temperature to obtain an aqueous solution of green fluorescent carbon quantum dots. The solution was then centrifuged at 10,000 rpm for 15 minutes to remove large solid precipitates. The liquid was transferred into a 1200Da molecular weight dialysis bag for dialysis for 72 hours, and the liquid in the dialysis bag was collected. The collected inner liquid is freeze-dried repeatedly to obtain solid powder, which is the green fluorescent carbon quantum dot. Taking rhodamine 6G as a reference substance, the fluorescence quantum yield of the carbon quantum dot is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com