Polyether polyol, preparation method thereof, preparation method of polyether amine and prepared polyether amine

A technology of polyether polyol and polyether amine, which is applied in the field of preparation of polyether amine and anti-yellowing polyether polyol, can solve the problems of harsh carrier pore size distribution, reduced catalyst activity, uneven metal dispersion, etc. Polymerization and polymerization reaction, improve activity and selectivity, improve the effect of raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

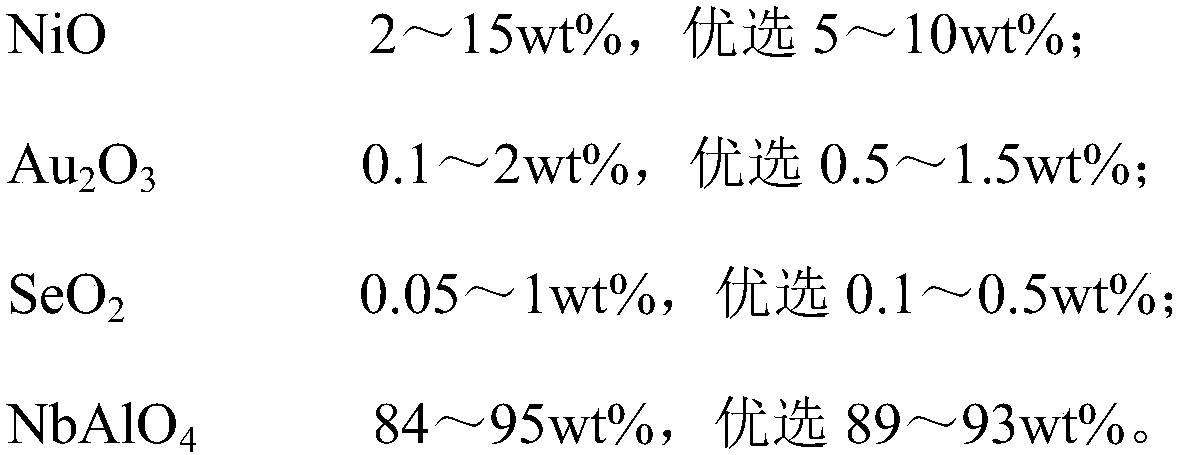

[0079] (1) 7wt% NiO-1wt% Au 2 o 3 -0.2wt%SeO 2 / NbAlO 4 Catalyst preparation

[0080] 99.1g Nb(OH) 5 and 28.5g Al 2 o 3 Add it into a mortar and mix evenly, grind and sieve to obtain a mixture of 100-200 meshes, then transfer the mixture to a crucible, dry at 110°C for 14h, and then bake in air at 1050°C for 20h (heating rate : 3°C / min; the heating rate refers to the temperature rising from room temperature to the final temperature at a determined rate per minute). Productive rate: 100g white powder (X-ray diffraction analysis shows that purity is higher than 98% NbAlO 4 ). A columnar carrier of 3*3mm is obtained through tablet molding.

[0081] According to the content and composition of the catalyst, the above carrier was impregnated with 29.7gNi(NO 3 ) 3 ·6H 2 O, 1.68gAu(NO 3 ) 3 and 0.25gH 2 SeO 3 In the aqueous solution, after the adsorption equilibrium, it was dried at 110°C for 6h, and then calcined in the air at 450°C for 11h to obtain the catalyst prec...

Embodiment 2

[0103] (1) 10wt% NiO-0.7wt% Au 2 o 3 -0.3wt%SeO 2 / NbAlO 4 Catalyst preparation

[0104] 136.0g Nb 2 (CO 3 ) 5 and 28.5g Al 2 o 3 Add it into a mortar and mix evenly, grind and sieve to obtain a mixture of 100-200 meshes, then transfer the mixture to a crucible, dry at 150°C for 8h, and then bake in air at 900°C for 24h (heating rate : 5°C / min. The heating rate refers to the temperature rising from room temperature to the final temperature at a certain rate per minute). Productive rate: 100g white powder (X-ray diffraction analysis shows that purity is higher than 98% NbAlO 4 ). A columnar carrier of 3*3mm is obtained through tablet molding.

[0105] According to the content and composition of the catalyst, the above carrier was impregnated with 43.7g Ni(NO 3 ) 3 ·6H 2 O, 1.21g Au(NO 3 )3 and 0.39g H 2 SeO 3 In the aqueous solution, after the adsorption equilibrium, it was dried at 130°C for 4h, and then calcined in the air at 300°C for 14h to obtain the catal...

Embodiment 3

[0116] (1) 5wt% NiO-0.8wt% Au 2 o 3 -0.5wt%SeO 2 / NbAlO 4 Catalyst preparation

[0117] 226.5g Nb(NO 3 ) 5 and 28.5g Al 2 o 3 Add it into a mortar and mix evenly, grind and sieve to obtain a mixture of 100-200 mesh, then transfer the mixture to a crucible, dry at 130°C for 10h, and then bake in air at 1100°C for 22h (heating rate : 4 ℃ / min. The rate of temperature rise refers to that the temperature is raised to the final temperature from room temperature at a certain rate per minute.) Productive rate: 100g white powder (X-ray diffraction analysis shows that it is NbAlO with a purity higher than 97%) 4 ). A 3*3mm strip carrier is obtained through extrusion molding.

[0118] According to the content and composition of the catalyst, the above carrier was impregnated with 20.8g Ni(NO 3 ) 3 ·6H 2 O, 1.32g Au(NO 3 ) 3 and 0.62g H 2 SeO 3 In the aqueous solution, after the adsorption equilibrium, it was dried at 100°C for 8h, and then calcined in the air at 400°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com