Method for modifying electrode of lithium ion battery

A lithium-ion battery and modification technology, which is applied in the field of modification of lithium-ion battery electrodes, can solve the problems of easy falling off and inertization of microspheres, achieve stable charge and discharge capacity, and solve the problems of partial inertization and easy falloff of microspheres Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

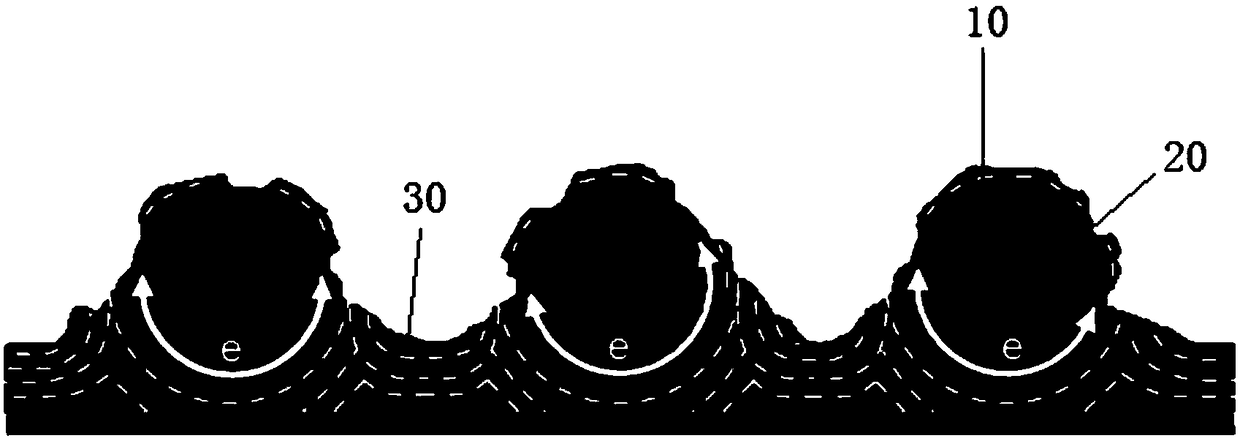

[0022] Based on [70 (cobalt carbonate): 20 (acetylene black): 10 (PVDF), parts by weight] cobalt carbonate negative electrode sheet S0 (attached figure 1 ), the modification scheme provided by the present embodiment is: replace PVDF with PEDOT:PSS as binder, and the realization method is: after mixing cobalt carbonate microspheres and acetylene black with D50 of 5 μm, press the ratio of predetermined binder Add a PEDOT:PSS aqueous solution with a solid content of 5wt%, stir well and heat at 40°C to achieve a coatable viscosity, then coat a film on a copper foil and dry to obtain a modified electrode S1[70 (cobalt carbonate): 20 (acetylene black): 10 (PEDOT:PSS)] (see figure 2 , which includes microspheres 1, acetylene black 3 and adhesive 2).

Embodiment 2

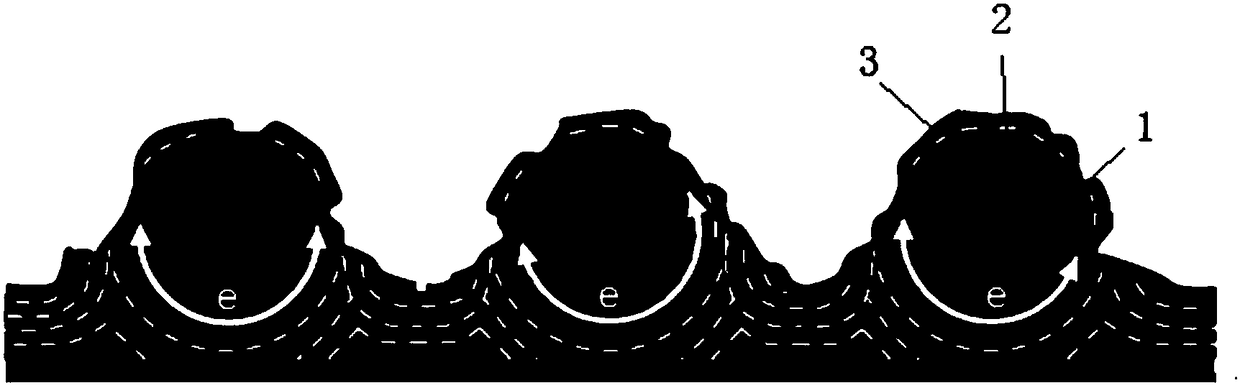

[0024] Based on [70 (cobalt carbonate): 20 (acetylene black): 10 (PVDF), parts by weight] cobalt carbonate negative electrode sheet S0 (attached figure 1 ), the modification scheme provided in this embodiment is: coating a layer of PEDOT:PSS coating on the surface of the S0 pole piece. The implementation method is: on the surface of the coated and dried S0 pole piece, apply a thin layer (thickness of 50nm) of PEDOT:PSS aqueous solution with a solid content of 1.5wt% by scraping, and obtain PEDOT:PSS conductive Coated modified electrode S2 (see image 3 , which includes microspheres 1, adhesive 2 and conductive coating 3), wherein the thickness of the PEDOT:PSS conductive coating is in the range of 20-100nm.

Embodiment 3

[0026] Based on [70 (cobalt carbonate): 20 (acetylene black): 10 (PVDF), parts by weight] cobalt carbonate negative electrode sheet S0 (attached figure 1 ), the modified scheme provided in this embodiment is:

[0027] The first step is to use PEDOT:PSS instead of PVDF as the binder. The specific implementation method is: after mixing cobalt carbonate microspheres with a D50 of 5 μm and acetylene black, add a solid content of 5wt% according to the predetermined binder ratio PEDOT: PSS aqueous solution, fully stirred and heated at 40 °C to achieve a coating viscosity, then coated on copper foil, dried, and obtained modified electrode S1 [70 (cobalt carbonate): 20 (acetylene black): 10 ( PEDOT:PSS)].

[0028] The second step is to coat a layer of PEDOT:PSS conductive coating on the surface of the S0 pole piece. The specific implementation method is: on the surface of the S1 pole piece that has been coated and dried, apply a thin layer of solid content of 1.5wt% PEDOT:PSS aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com