Preparation method of reduced graphene oxide/bioglass nanofiber scaffold

A technology of biological glass and nanofibers, applied in tissue regeneration, pharmaceutical formulation, drug delivery, etc., can solve the problem of low chemical activity of hydroxyl groups, achieve high biological activity, high porosity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

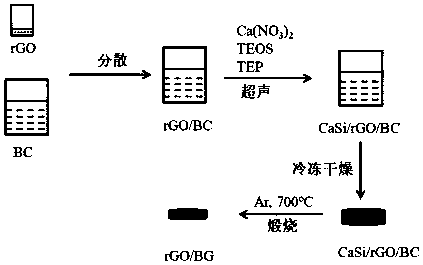

Method used

Image

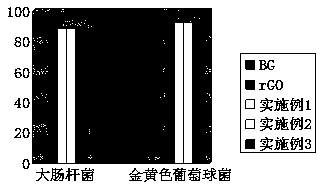

Examples

Embodiment 1

[0023] A preparation method for a highly bioactive nano glass fiber support, comprising the following steps:

[0024] (1) Weigh the granular bacterial cellulose (BC) block, put it in a cell wall breaking machine, add water and beat it into a slurry, and make a bacterial cellulose slurry solution with a mass concentration of 20%;

[0025] (2) Add graphene oxide with a mass ratio of 1%, put it in an ultrasonic machine for 1 h, and obtain a uniform dispersion solution of graphene oxide, raise the temperature to 100 °C, and add hydrazine hydrate solution dropwise to it for 1 h, and then carry out Centrifuge to obtain a reduced graphene oxide solution (rGO), wherein the mass ratio of graphene oxide to hydrazine hydrate solution is 1:1000;

[0026] (3) The bacterial cellulose solution in (1) and the reduced graphene oxide solution in (2) are mixed with ultrasound in a volume ratio of 10:1 to obtain a reduced graphene oxide / bacterial cellulose mixed solution (rGO / BC);

[0027] (3)...

Embodiment 2

[0030] A preparation method for a highly bioactive nano glass fiber support, comprising the following steps:

[0031] (1) Weigh the granular bacterial cellulose (BC) block, put it in a cell wall breaking machine, add water and beat it into a slurry, and make a bacterial cellulose slurry solution with a mass concentration of 20%;

[0032] (2) Add graphene oxide with a mass ratio of 1%, put it in an ultrasonic machine for 1 h, and obtain a uniform dispersion solution of graphene oxide, raise the temperature to 100 °C, and add hydrazine hydrate solution dropwise to it for 1 h, and then carry out Centrifuge to obtain a reduced graphene oxide solution (rGO), wherein the mass ratio of graphene oxide to hydrazine hydrate solution is 1:1000;

[0033] (3) The bacterial cellulose solution in (1) and the reduced graphene oxide solution in (2) are mixed with ultrasound in a volume ratio of 10:1 to obtain a reduced graphene oxide / bacterial cellulose mixed solution (rGO / BC);

[0034] (3)...

Embodiment 3

[0037] A preparation method for a highly bioactive nano glass fiber support, comprising the following steps:

[0038] (1) Weigh the granular bacterial cellulose (BC) block, put it in a cell wall breaking machine, add water and beat it into a slurry, and make a bacterial cellulose slurry solution with a mass concentration of 20%;

[0039] (2) Add graphene oxide with a mass ratio of 1%, put it in an ultrasonic machine for 1 h, and obtain a uniform dispersion solution of graphene oxide, raise the temperature to 100 °C, and add hydrazine hydrate solution dropwise to it for 1 h, and then carry out Centrifuge to obtain a reduced graphene oxide solution (rGO), wherein the mass ratio of graphene oxide to hydrazine hydrate solution is 1:1000;

[0040] (3) The bacterial cellulose solution in (1) and the reduced graphene oxide solution in (2) are mixed with ultrasound in a volume ratio of 10:1 to obtain a reduced graphene oxide / bacterial cellulose mixed solution (rGO / BC);

[0041] (3) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com