A kind of preparation method of bovine wool protein sponge adsorption material for tannery dyeing waste liquid

A technology for adsorbing materials and dyeing waste liquid, applied in chemical instruments and methods, adsorption water/sewage treatment, animal processing waste water treatment, etc. Biodegradability, the effect of increasing active reactive sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

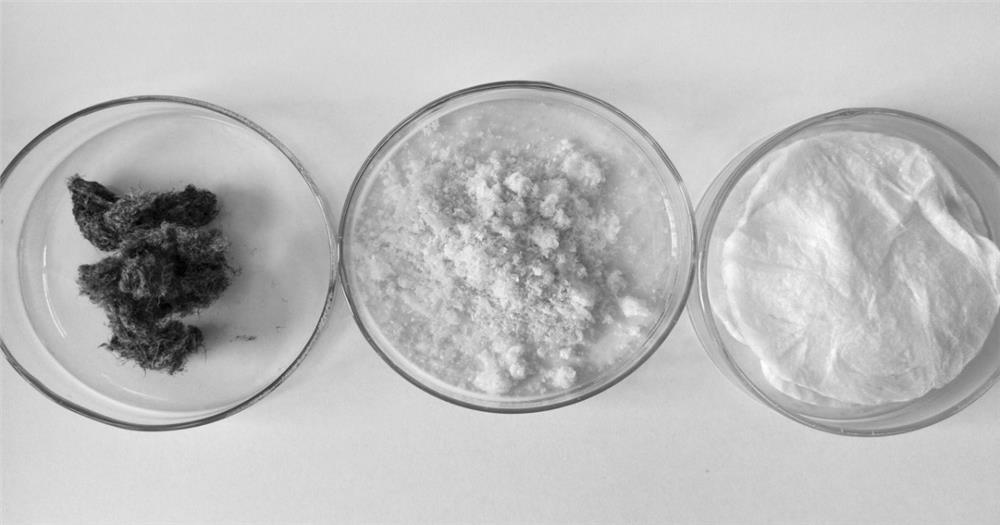

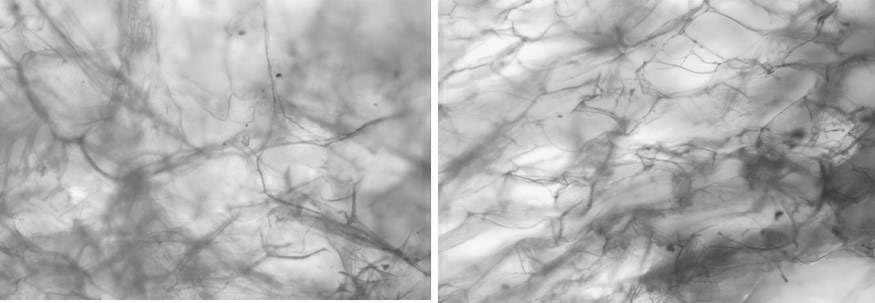

Image

Examples

Embodiment 1

[0032] (1) Sorting and removing impurities from cattle hair: Soak and wash cattle hair with 15 times of clean water for 6 hours, pick out the grass and sawdust floating on the surface and insoluble solid impurities such as gravel and meat pieces that sink to the bottom, and then drain the hair Dry. The cow hair that has been preliminarily removed is put into an ultrasonic cleaner, soaked and rinsed 3 times with 15 times the pretreatment solution containing 2% sodium bicarbonate and penetrant JFC, and at the same time supplemented by ultrasonic vibration, the ultrasonic frequency is 50KHz, The temperature is 25°C, 30 minutes each time, to remove soluble impurities such as grease and sulfide, the obtained wet cow hair is placed on a tray, spread evenly, and dried at 60°C for 8 hours.

[0033] (2) Ionic liquid pretreatment of cow hair: put the cow hair removed from step (1) into a three-necked flask, and blow nitrogen into it, then add 1-butyl-3-methylimidazole acetate 5 times th...

Embodiment 2

[0037] (1) Sorting and removing impurities from cattle hair: Soak and wash cattle hair with 17 times of clean water for 5.5 hours, pick out the grass and sawdust floating on the surface and insoluble solid impurities such as gravel and meat pieces at the bottom, and then drain the hair Dry. Put the cow hair that has been preliminarily removed into an ultrasonic cleaner, soak it with 20 times the pretreatment solution containing 1.5% sodium dodecylbenzenesulfonate, and rinse it for 3 times, and at the same time, it is supplemented by ultrasonic vibration, and the frequency of the ultrasonic wave is 40KHz , the temperature is 30°C, 30 minutes each time, to remove soluble impurities such as grease and sulfide, the obtained wet cow hair is placed in a tray, spread evenly, and dried at 70°C for 7 hours.

[0038] (2) Ionic liquid pretreatment of cow hair: put the cow hair removed from impurities in step (1) into a three-necked bottle, and blow nitrogen into it, then add 1-butyl-3-me...

Embodiment 3

[0042] (1) Sorting and removing impurities from cattle hair: Soak and wash cattle hair with 19 times of clean water for 5 hours, pick out the grass and sawdust floating on the surface and insoluble solid impurities such as gravel and meat pieces that sink to the bottom, and then drain the hair Dry. Put the cow hair that has been preliminarily removed into an ultrasonic cleaner, soak and rinse twice with 17 times the pretreatment solution containing 2.5% sodium oleate, and at the same time supplement it with ultrasonic vibration. The frequency of the ultrasonic wave is 30KHz and the temperature is 35°C. , 30 minutes each time, to remove soluble impurities such as grease and sulfide, place the obtained wet cow hair on a tray, spread it evenly, and dry it at 80°C for 5 hours.

[0043] (2) Ionic liquid pretreatment of cow hair: put the cow hair removed from impurities in step (1) into a three-necked bottle, and pass nitrogen gas, and then add 1-ethyl-3-methylimidazole acetic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com