Preparation method of nano composite MoS2/Ag/TiO2 NTs

A nanocomposite material, reduction method technology, applied in catalyst activation/preparation, nanotechnology, nanotechnology and other directions, can solve the problems of limiting the formation of photocatalytic reaction devices, low catalytic oxidation activity, unfavorable absorption and reflection, etc. The effect of recombination probability, improving photocatalytic efficiency and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

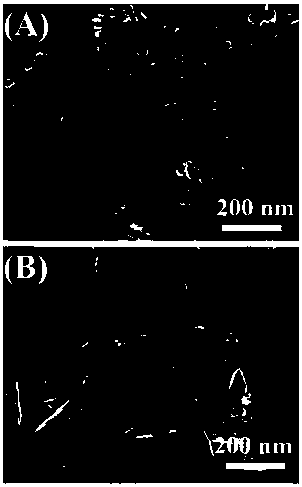

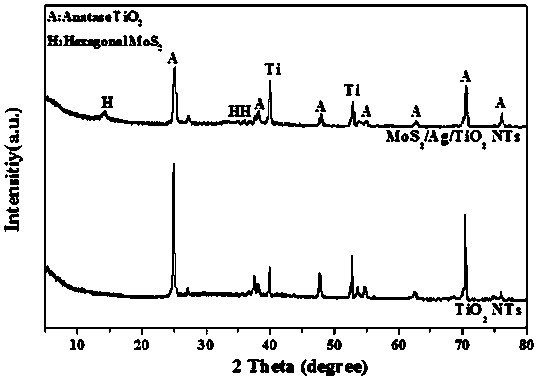

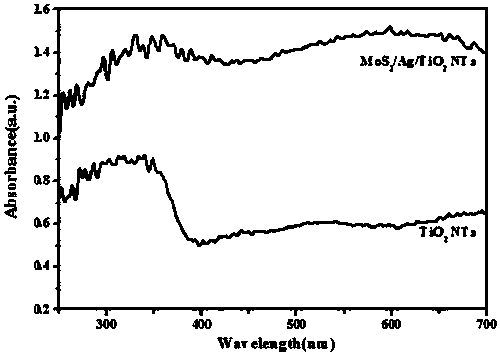

[0020] The nanocomposite material MoS of this embodiment 2 / Ag / TiO2 The preparation method of NTs is as follows:

[0021] (1) Titanium mesh pretreatment: ultrasonically clean the titanium mesh with acetone, ethanol, and deionized water in turn for later use; (2) Preparation of organic electrolyte: 40 mL of dimethyl sulfoxide solution containing 2wt% hydrofluoric acid; ( 3) Anodization of titanium mesh: under 40 V DC voltage, with platinum sheet (L×W=3×1 cm) as cathode and titanium mesh (L×W=3×2 cm) as anode, in the electrolyte Preparation of titanium oxide nanotubes by electrolysis for 8 hours; (4) Crystallization of titanium oxide nanotubes: calcining the titanium oxide nanotubes prepared in the above steps under aerobic conditions at 450~550°C for 2~4 hours to crystallize them into TiO 2 NTs. (5) Ag / TiO 2 Preparation of NTs mesh: the TiO 2 NTs / Ti mesh (effective area 2cm×2cm) was immersed in 0.06mol / L AgNO 3 solution, 40kHz ultrasonic treatment for 30 minutes, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com