Modified bismaleimide resin applicable to resin transfer molding process and preparation method of modified bismaleimide resin

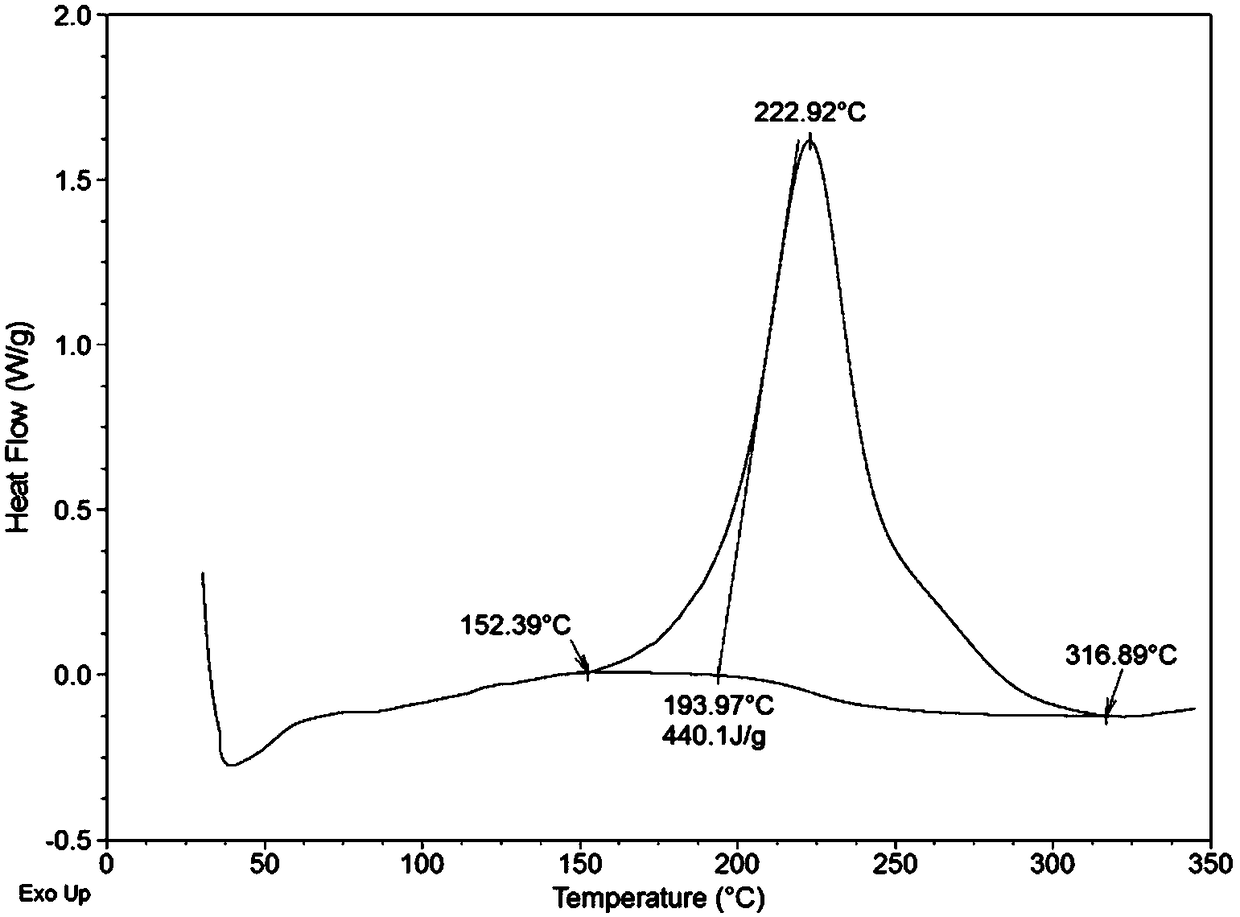

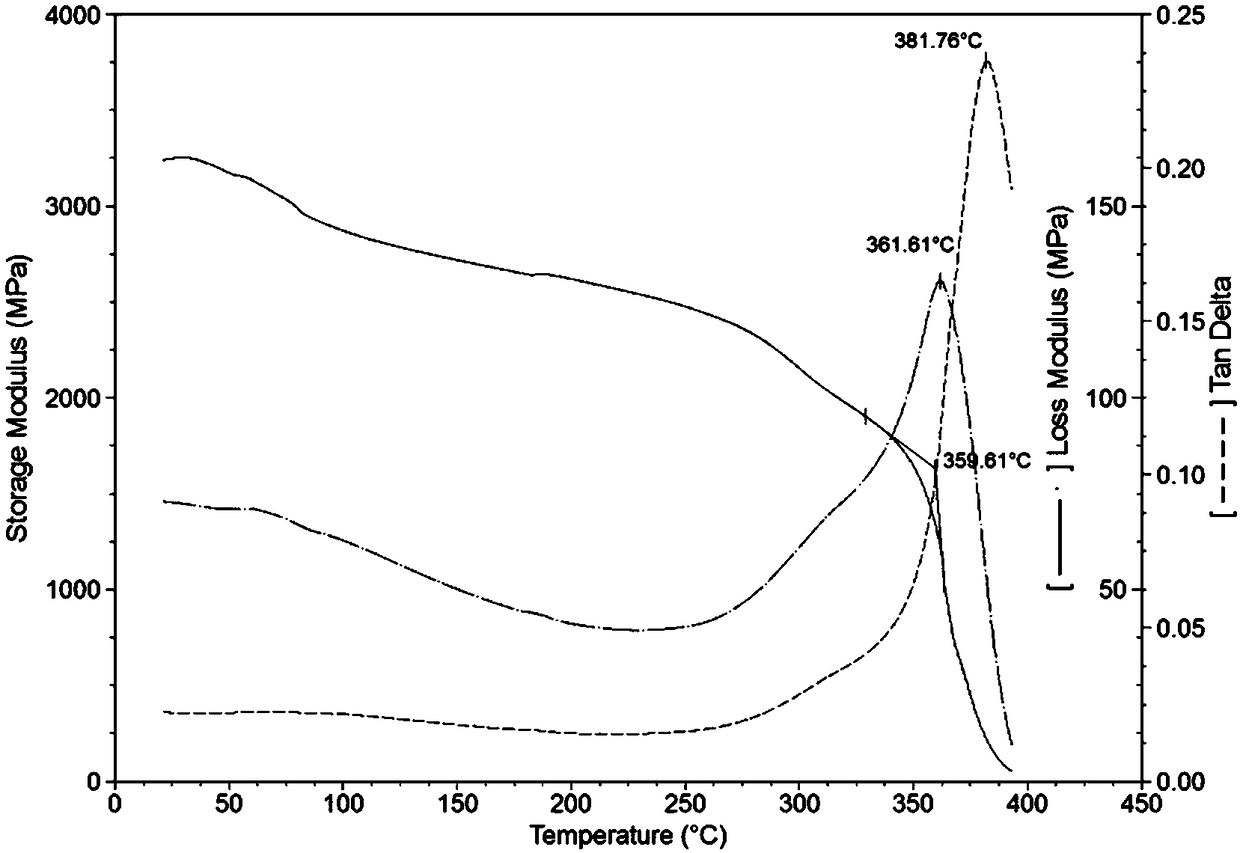

A technology of bismaleimide resin and bismaleimide, which is applied in the field of modified bismaleimide resin and its preparation, can solve the problem of the dielectric properties of bismaleimide resin. There is less research work on improvement and evaluation, and it is difficult to take into account the improvement of heat resistance, processing technology, and heat resistance weakening, so as to achieve the effects of excellent processing technology, improved dielectric properties, and excellent heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

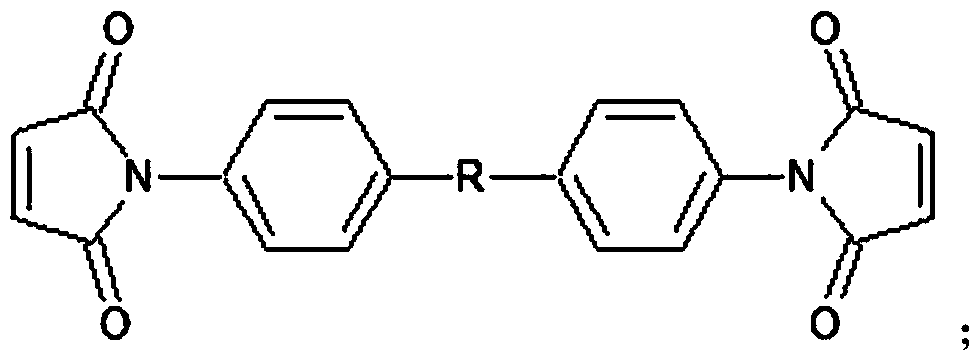

[0054] In a 500ml glass bottle equipped with a thermometer, an addition funnel and a mechanical stirring device, add 50g of 1-allyl-2-cyanatobenzene, raise the temperature to 140°C, and add 100g of 4,4' within 1 hour - bismaleimide diphenylmethane, and continue to keep warm at 140° C. for 1 hour, and the system is in a homogeneous and transparent state at this time. Cool the system down to 120°C, add 50g of 3-aminobenzocyclobutene, readjust the system temperature to 120°C, add 100g of 4,4′-bismaleimide diphenylmethane within 1 hour, and continue The reaction was incubated at 120° C. for 1 hour. Cool down to obtain a reddish-brown homogeneous and transparent modified bismaleimide resin.

Embodiment 2

[0056] In a 500ml glass bottle equipped with a thermometer, an addition funnel and a mechanical stirring device, add 30g of 1-allyl-2-cyanatobenzene, raise the temperature to 140°C, and add 75g of 4,4' within 1 hour - bismaleimide diphenylmethane, and continue to keep warm at 140° C. for 1 hour, and the system is in a homogeneous and transparent state at this time. Cool the system down to 120°C, add 60g of 3-aminobenzocyclobutene, readjust the system temperature to 120°C, add 120g of 4,4'-bismaleimide diphenylmethane within 1 hour, and continue The reaction was incubated at 120° C. for 1 hour. Cool down to obtain a reddish-brown homogeneous and transparent modified bismaleimide resin.

Embodiment 3

[0058] In a 500ml glass bottle equipped with a thermometer, an addition funnel and a mechanical stirring device, add 60g of 1-allyl-2-cyanatobenzene, raise the temperature to 140°C, and add 120g of 4,4' within 1 hour - bismaleimide diphenylmethane, and continue to keep warm at 140° C. for 1 hour, and the system is in a homogeneous and transparent state at this time. Cool the system down to 120°C, add 30g of 3-aminobenzocyclobutene, readjust the system temperature to 120°C, add 45g of 4,4'-bismaleimide diphenylmethane within 1 hour, and continue The reaction was incubated at 120° C. for 1 hour. Cool down to obtain a reddish-brown homogeneous and transparent modified bismaleimide resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com