Rare-earth waste recovering and machining and treatment device system and rare-earth waste recovering and machining and treatment method

A rare earth waste and processing device technology, which is applied in the direction of improving process efficiency, can solve the problems of high purity of rare earth oxides, reduce the recovery rate of rare earth, increase the consumption of acid treatment, etc., so as to reduce the cost of recycling and processing, shorten the roasting time, Effect of reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

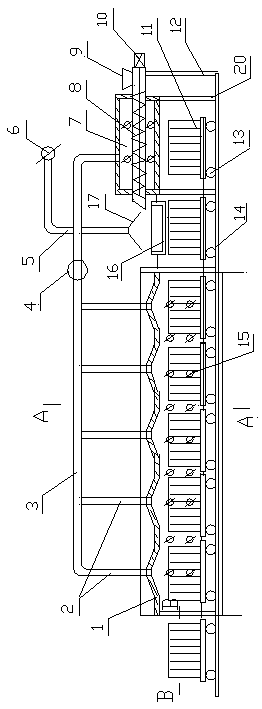

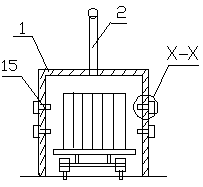

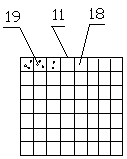

[0023] exist Figure 2 to Figure 6 Among them, the rare earth waste recycling processing device system described in the present invention includes a roaster for converting rare earth waste into rare earth oxides and converting iron-containing materials into iron oxide materials, a reactor for hydrochloric acid, water and materials, and extracting device, storage tank, centrifugal mixer, filtration sedimentation device and burning furnace, each component of above system is except roasting furnace and filtration sedimentation device, and all the other parts are prior art, and the roasting furnace in the system of the present invention The following structure is adopted: the roasting furnace includes a tunnel-type heat preservation furnace body 1, a plurality of trolleys 13 that can be driven at intervals by an external force on the guide rail 14 in the furnace body, and a carrier 11 arranged on the trolley, the carrier is High-temperature-resistant ceramic honeycomb body, the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com