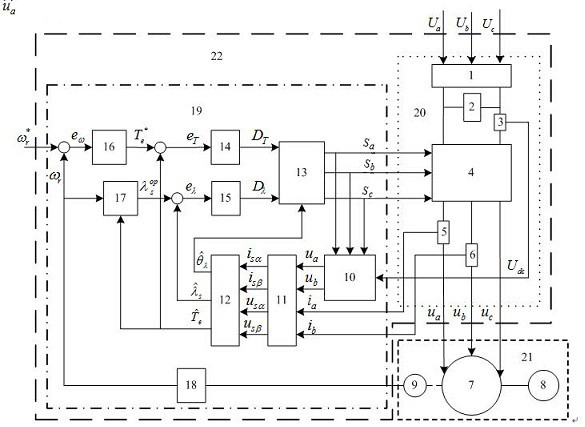

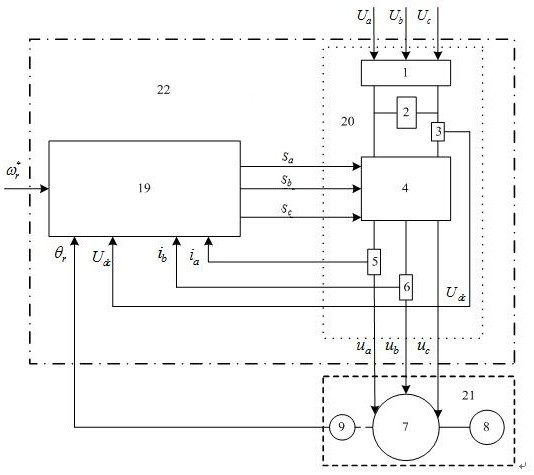

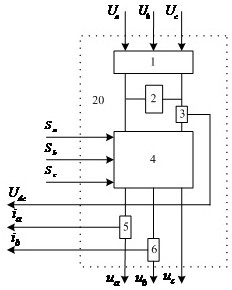

Built-in permanent magnet synchronous motor direct torque control energy-saving frequency converter and its construction method

A technology of permanent magnet synchronous motor and direct torque control, which is applied in motor control, motor generator control, AC motor control, etc., and can solve the problems that high performance and high efficiency cannot be taken into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Control attached Figure 7 , The energy-saving frequency conversion controller adopts the digital signal processor (DSP) to realize through software programming. The DSP controller adopts the motor control special chip TMS320F2812 of TI Company, the power inverter adopts the intelligent power module PS21865 of Mitsubishi Company, and the Hall sensor adopts two LM25-NP and one LV25-NP of Swiss LEM Company. The model of the AC permanent magnet synchronous motor is 130SFM_E050254, and its parameters are: P N =1.3kW, rated voltage U N =220V, rated speed n N =2500r / min, rated torque T N =5Nm, stator resistance R s =1.35Ω, core loss resistance R fe =305Ω, stator d-axis inductance L d =7.76mH, stator q-axis inductance L q =17mH, rotor inertia J=0.003kg·m 2 , Viscous friction coefficient b = 0.001Nm·s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com