Treatment method and device for sulfate and chromate compound polluted wastewater

A technology of sulfate chromate and compound pollution, which is applied in the fields of special compound water treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Thorough, trivalent chromium is difficult to fix and other problems, to achieve the effect of good removal effect, cheap raw materials, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

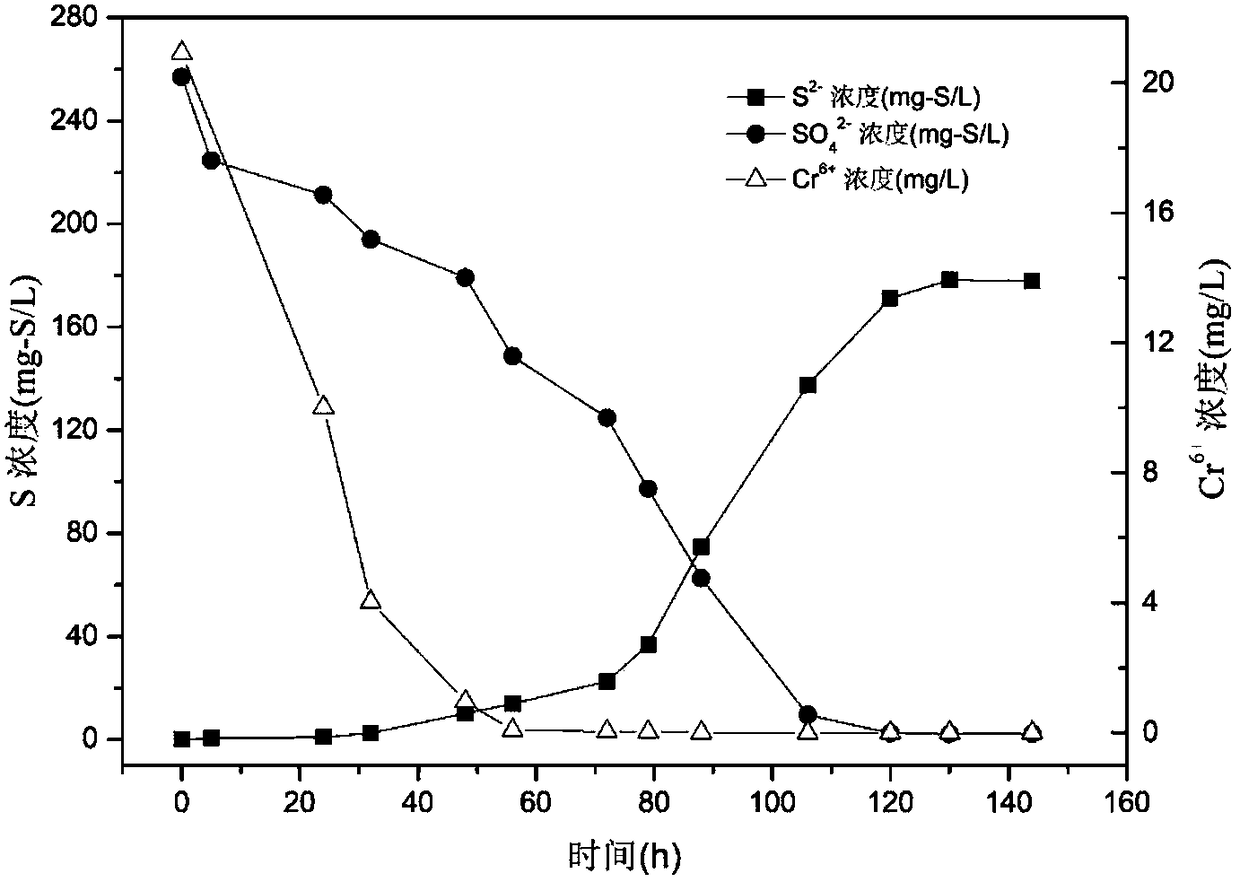

[0021] In the sludge domestication stage, the sludge from the secondary settling tank and 180mL of simulated wastewater containing Cr(VI) (20mg / L) were added to a 200mL stoppered Erlenmeyer flask, and 5g of degradable biological lunch boxes were added to expose to N 2 For 20 minutes, the anaerobic environment was maintained, and the acclimatization of the sludge and the filming of the biodegradable lunch box were carried out at 35°C and 150 rpm. Change the water every 5-6 days and detect the sulfate and chromium content in the supernatant. After 40 days of domestication, the sludge is black and has a strong smell of rotten eggs, and a layer of biofilm hangs on the surface of the biodegradable lunch box And sulfate and chromium achieve stable removal. At this time, it is considered that the domestication of the sludge is completed, and the film-forming of the bio-reduced lunch box is successful.

[0022] Simulated wastewater (g / L): NaSO 4 (2.5±0.5), K 2 HPO 4 0.5, NH 4 C...

Embodiment 2

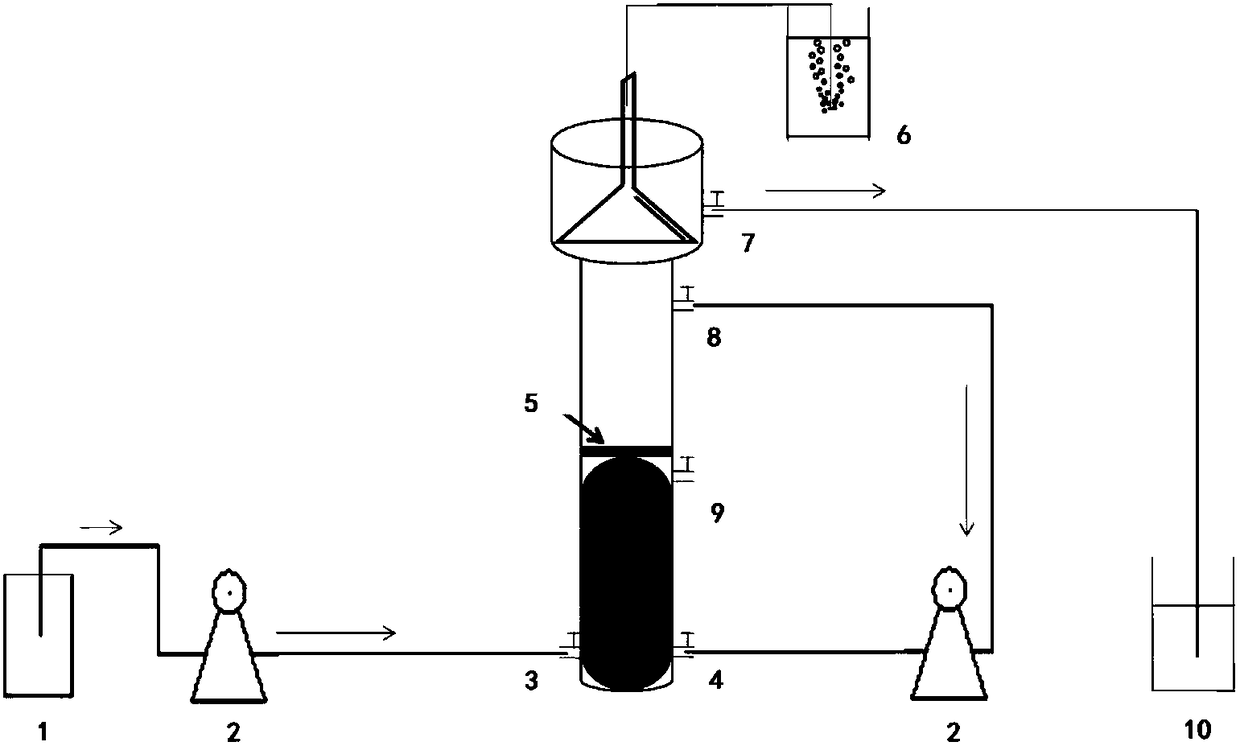

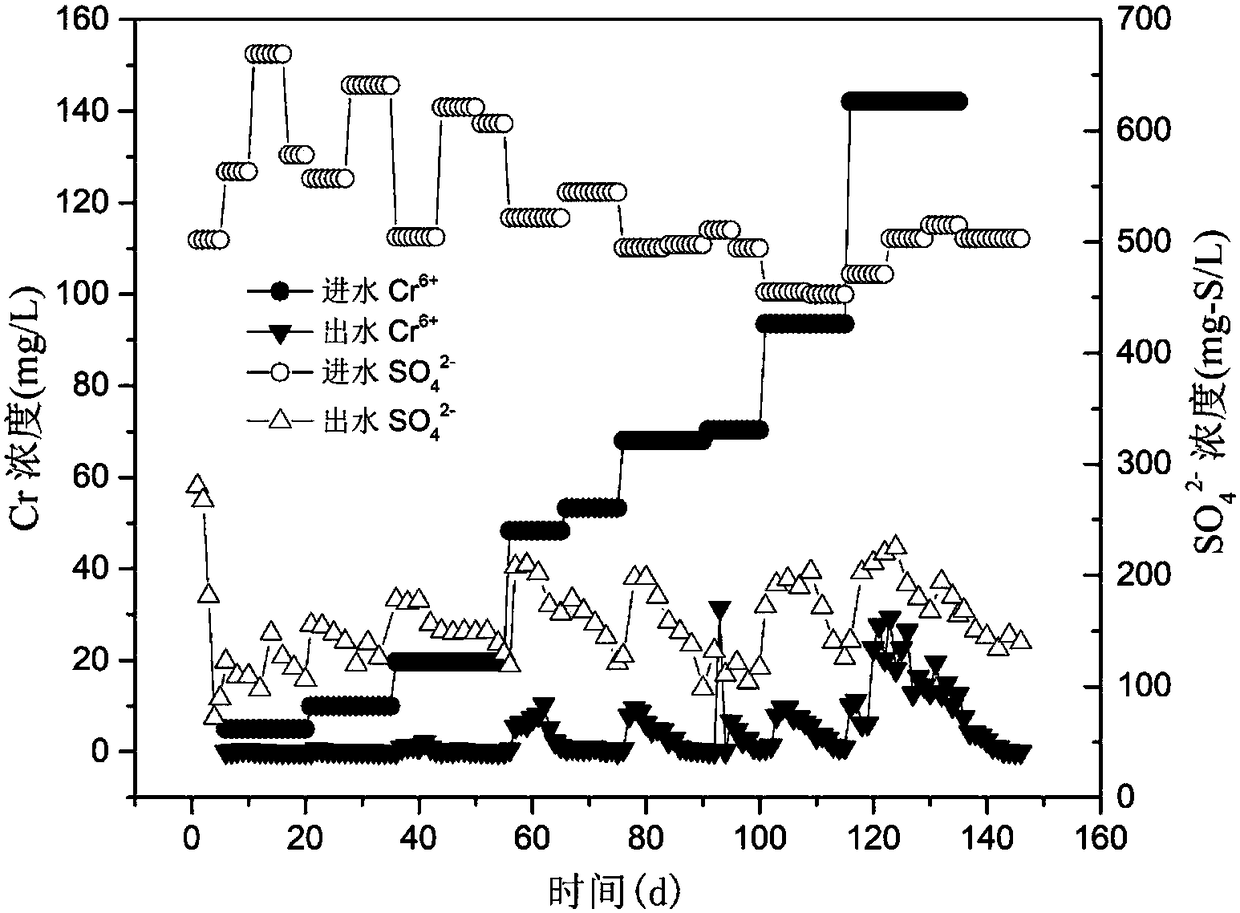

[0025] In an 80mm inner diameter, 900mm high, 50g biodegradable lunch box was added to the anaerobic packed bed device, the filling height of the biodegradable lunch box was 300mm, and the simulated wastewater containing Cr(VI) (2 After 20 minutes, it enters the reactor through the control of the peristaltic pump. The stable operating conditions are: the reaction temperature is 35°C, the pH of the reaction is adjusted to 7.0, the reflux ratio is 2:1, and the hydraulic retention time is 24h.

[0026] The effluent quality is as follows (unit: mg / L): SO 4 2- : 110±10.254, S 2- : not detected, COD: not detected, Cr(VI): 1.345±0.012, Cr(III): not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com