System for removing refractory COD (Chemical Oxygen Demands) and removal method thereof

A refractory and biodegradable technology, applied in the removal of refractory COD system and its removal field, can solve the problems of water pollution, increase the difficulty of system treatment, investment and operation costs, increase the content of salt and iron ion content, and achieve COD treatment High load, high COD removal effect, and stable removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

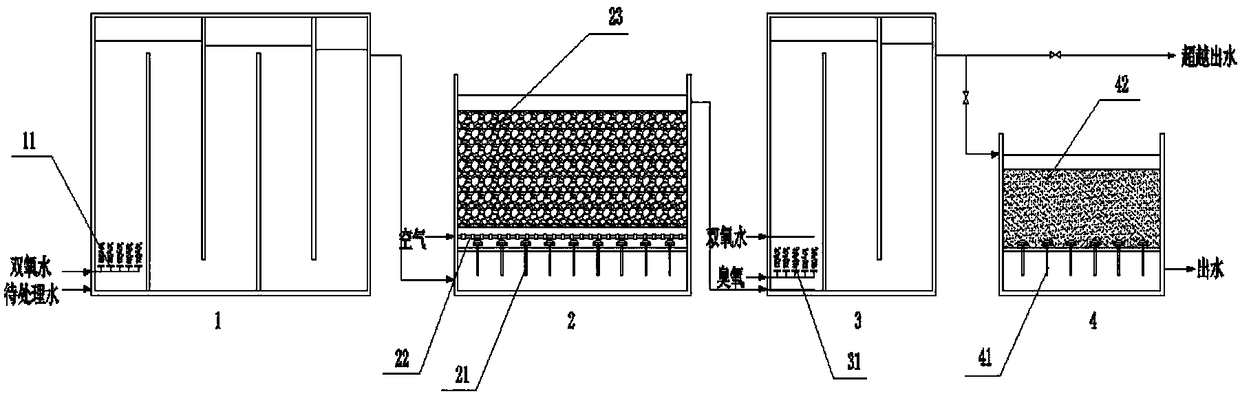

[0037] Reverse osmosis concentrated water from a petroleum refinery wastewater advanced treatment process (refractory COD in reverse osmosis concentrated water is converted into oils, polycyclic aromatic hydrocarbons, and aromatic amines):

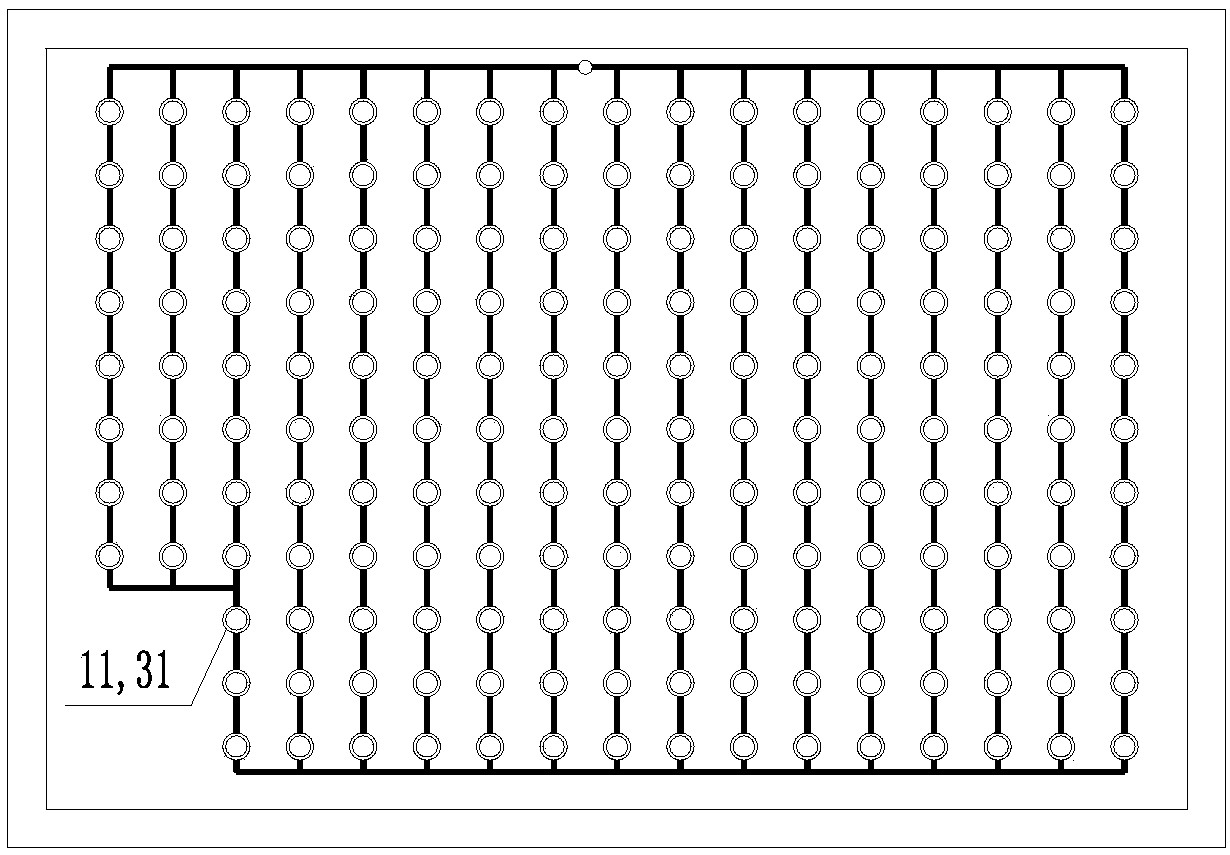

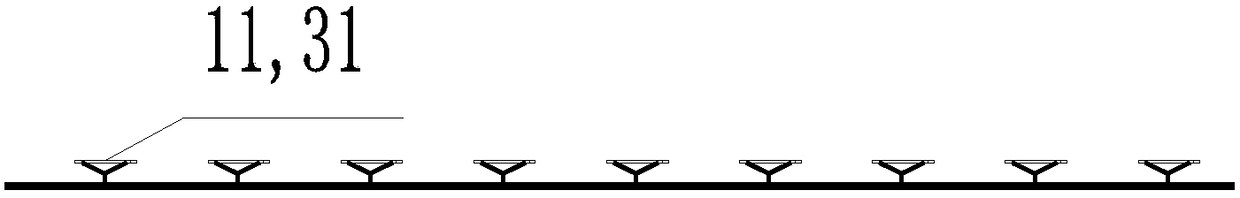

[0038] The dosage of ozone in the ozone oxidation tank is 126mg / L, and the amount of each gas distribution device in the biological aerated filter is 0.24m 3 / (unit h), the amount of ozone added in the ozone / hydrogen peroxide synergistic oxidation tank is 154mg / L, the amount of hydrogen peroxide added is 105mg / L, the filtration rate of the activated carbon filter is 8m / h, and the residence time is 15min.

[0039] Influent COD=175mg / L sewage enters the ozone oxidation pool, the effective water depth of the ozone oxidation pool is 6m, adopts the vertical flow corridor type, the water inlet is located at the bottom of the first corridor, and the ozone aeration plate is located on the upper part of the water inlet. In the ozone oxidation tank,...

Embodiment 2

[0041] Reverse osmosis concentrated water from a petroleum refinery wastewater advanced treatment process (refractory COD in reverse osmosis concentrated water is converted into oils, polycyclic aromatic hydrocarbons, and aromatic amines):

[0042] The dosage of ozone in the ozone oxidation tank is 120mg / L, and the amount of each gas distribution device in the biological aerated filter is 0.24m 3 / (unit h), the amount of ozone added in the ozone / hydrogen peroxide synergistic oxidation tank is 145mg / L, the amount of hydrogen peroxide added is 100mg / L, the filtration rate of the activated carbon filter is 6m / h, and the residence time is 18min.

[0043] Influent COD=170mg / L sewage enters the ozone oxidation tank, the effective water depth of the ozone oxidation tank is 6m, adopts the vertical flow corridor type, the water inlet is located at the bottom of the first corridor, and the ozone aeration plate is located on the upper part of the water inlet. In the ozone oxidation tank,...

Embodiment 3

[0045] Reverse osmosis concentrated water from a petroleum refinery wastewater advanced treatment process (refractory COD in reverse osmosis concentrated water is converted into oils, polycyclic aromatic hydrocarbons, and aromatic amines):

[0046] The dosage of ozone in the ozone oxidation tank is 135mg / L, and the air distribution volume of each gas distribution device in the biological aerated filter is 0.40m 3 / (unit h), the amount of ozone added in the ozone / hydrogen peroxide synergistic oxidation tank is 160mg / L, the amount of hydrogen peroxide added is 110mg / L, the filtration rate of the activated carbon filter is 10m / h, and the residence time is 12min.

[0047] Influent COD=180mg / L sewage enters the ozone oxidation tank, the effective water depth of the ozone oxidation tank is 6m, adopts vertical flow corridor type, the water inlet is located at the bottom of the first corridor, and the ozone aeration plate is located on the upper part of the water inlet. In the ozone o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com