Production process of potassium humate synergistic fertilizer

A production process, the technology of potassium humate, applied in the field of agriculture, can solve the problems of improving soil performance and increasing soil fertilizer efficiency, and achieve the effects of strong controllability of slow release time, improving soil structure and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

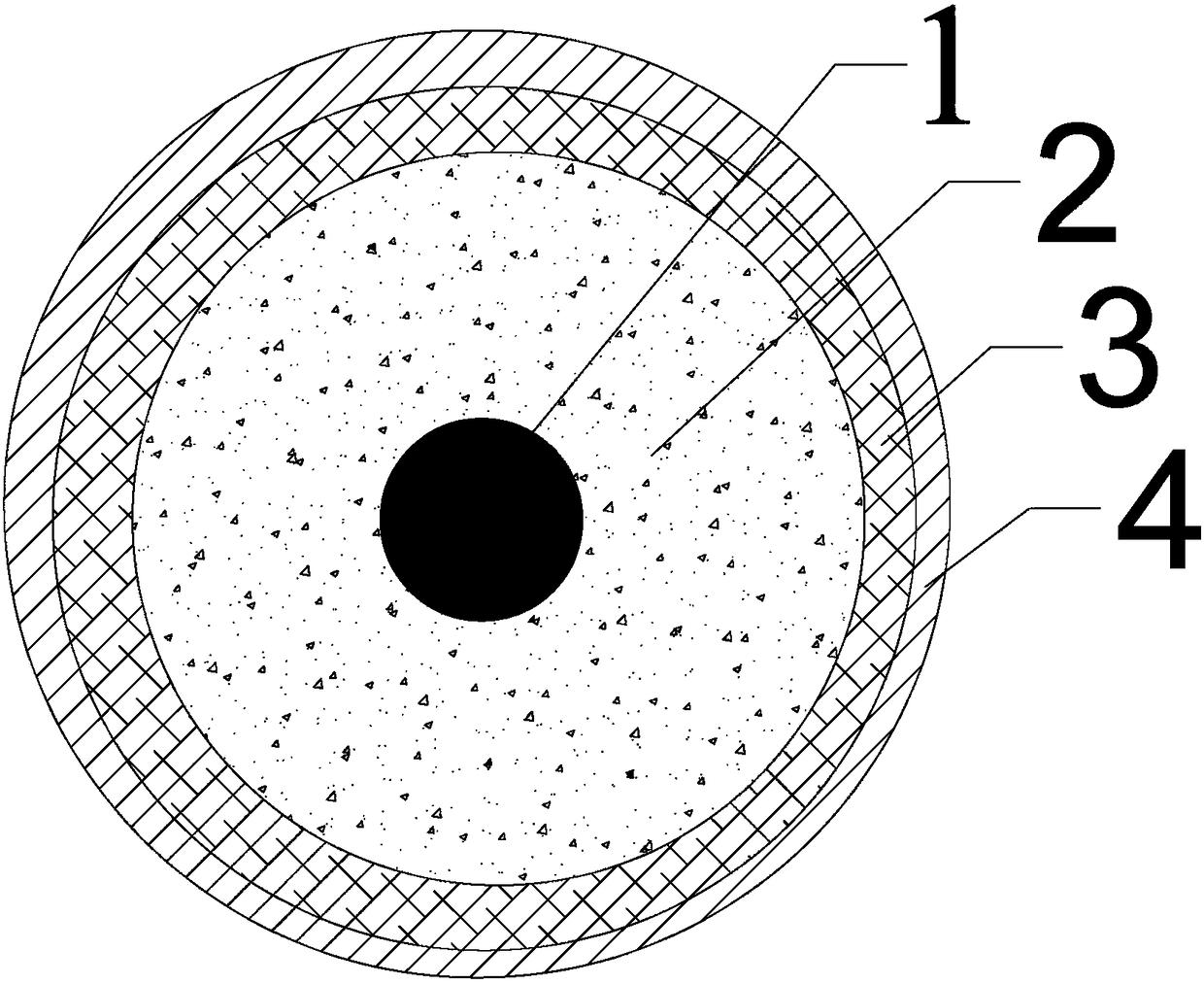

Image

Examples

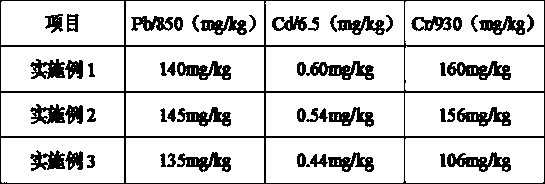

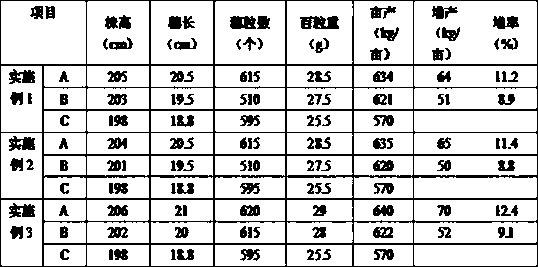

Embodiment 1

[0035] A kind of potassium humate synergistic fertilizer production process, comprises the steps:

[0036] Step 1, fermentation: crush the raw materials according to the ratio, add water with a mass fraction of 15% of the raw materials, and 5% starter, and ferment at 30°C for 10 hours; the starter is microbial fungus; the potassium humate is effective The ingredients and parts by weight of the fertilizer raw materials are: 35 parts of potassium humate, 10 parts of sesame cake, 8 parts of soybean straw, 8 parts of corn cake, 3 parts of urea, 3 parts of lignin, 2 parts of plant ash, 1 part of banana peel, 1 part of amino acid, 2 parts of potassium phosphate and 1 part of trace elements, the trace elements are selenium, iron and zinc in equal parts by weight;

[0037]Step 2, spraying: spray the fermented raw material evenly with the spraying liquid, then fumigate and grind to make powder; the spraying liquid is a plant growth regulator;

[0038] Step 3, core making, fully dry an...

Embodiment 2

[0045] A kind of potassium humate synergistic fertilizer production process, comprises the steps:

[0046] Step 1, fermentation: crush the raw materials according to the proportion, add water with a mass fraction of 20% of the raw materials, and 10% starter, and ferment at 50°C for 15 hours; the starter is microbial fungus; the potassium humate is synergistic The ingredients and parts by weight of fertilizer raw materials are: 45 parts of potassium humate, 15 parts of sesame cake, 12 parts of soybean straw, 12 parts of corn cake, 7 parts of urea, 7 parts of lignin, 4 parts of plant ash, 3 parts of banana peel, 3 parts of amino acids, 4 parts of potassium phosphate and 3 parts of trace elements, said trace elements being selenium, iron and zinc in equal parts by weight;

[0047] Step 2, spraying: spray the fermented raw material evenly with the spraying liquid, then fumigate and grind to make powder; the spraying liquid is a plant growth regulator;

[0048] Step 3, core making...

Embodiment 3

[0055] A kind of potassium humate synergistic fertilizer production process, comprises the steps:

[0056] Step 1, fermentation: crush the raw materials according to the ratio, add water with a mass fraction of 17% of the raw materials, and 7% starter, and ferment at 40°C for 12 hours; the starter is microbial fungus; the potassium humate is synergistic The ingredients and parts by weight of the fertilizer raw materials are: 40 parts of potassium humate, 12 parts of sesame cake, 10 parts of soybean straw, 10 parts of corn cake, 5 parts of urea, 5 parts of lignin, 3 parts of plant ash, 2 parts of banana peel, 2 parts of amino acids, 3 parts of potassium phosphate and 2 parts of trace elements, said trace elements being selenium, iron and zinc in equal parts by weight;

[0057] Step 2, spraying: spray the fermented raw material evenly with the spraying liquid, then fumigate and grind to make powder; the spraying liquid is a plant growth regulator;

[0058] Step 3, core making, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com