Method for preparing high-content d-gamma-tocopherol from mixed tocopherol concentrate

A technology of tocopherol and concentrated solution is applied in the field of preparation of high-content d-γ-tocopherol monomers, can solve the problems of unsuitability for industrialized production, difficult to scale up for industrialization, high equipment requirements and the like, and achieves simple steps, low consumption, Low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

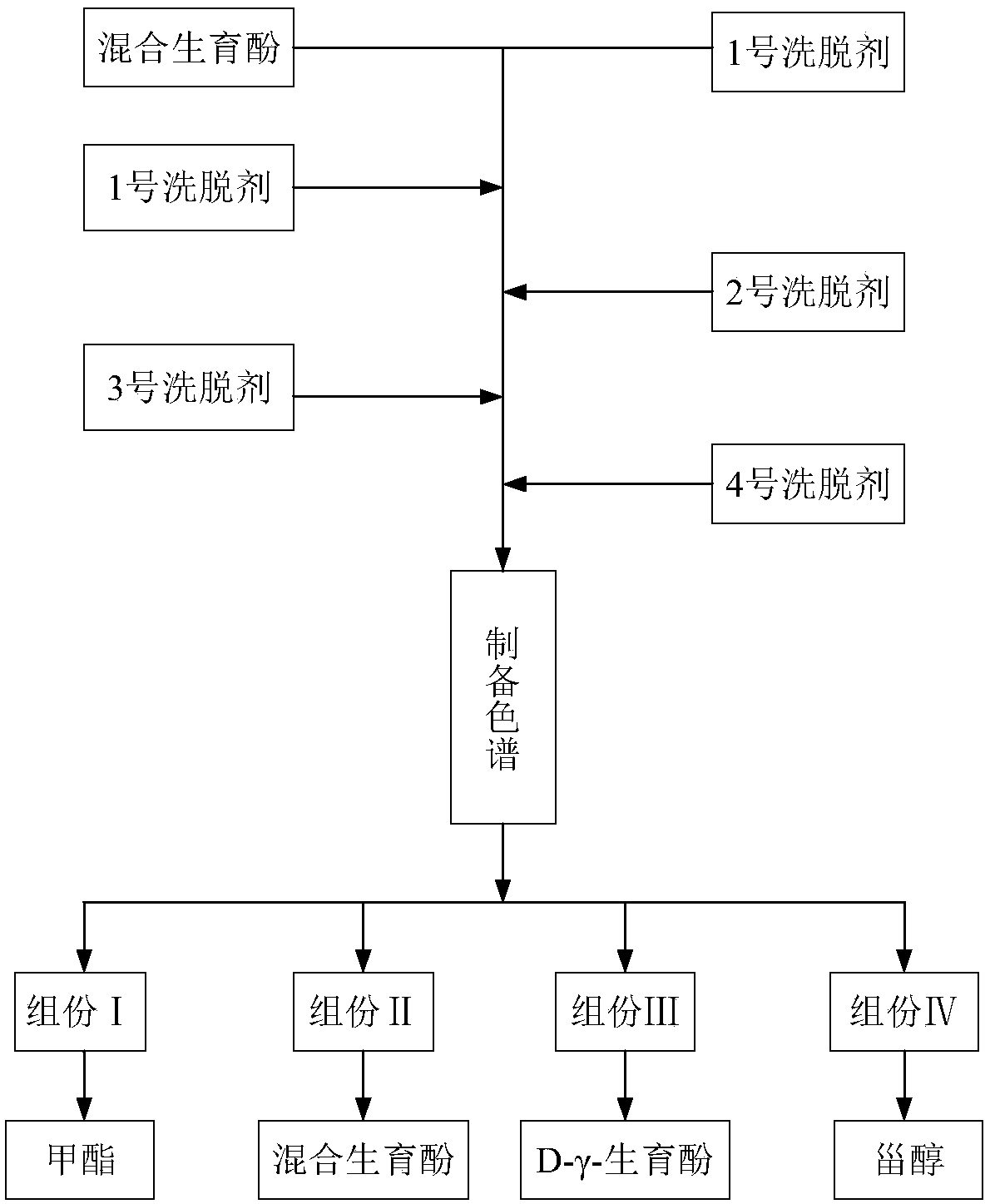

Method used

Image

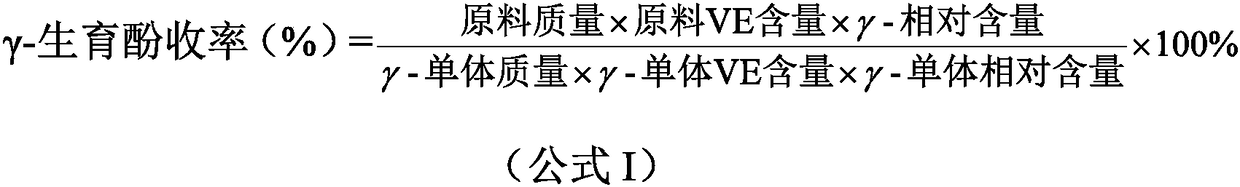

Examples

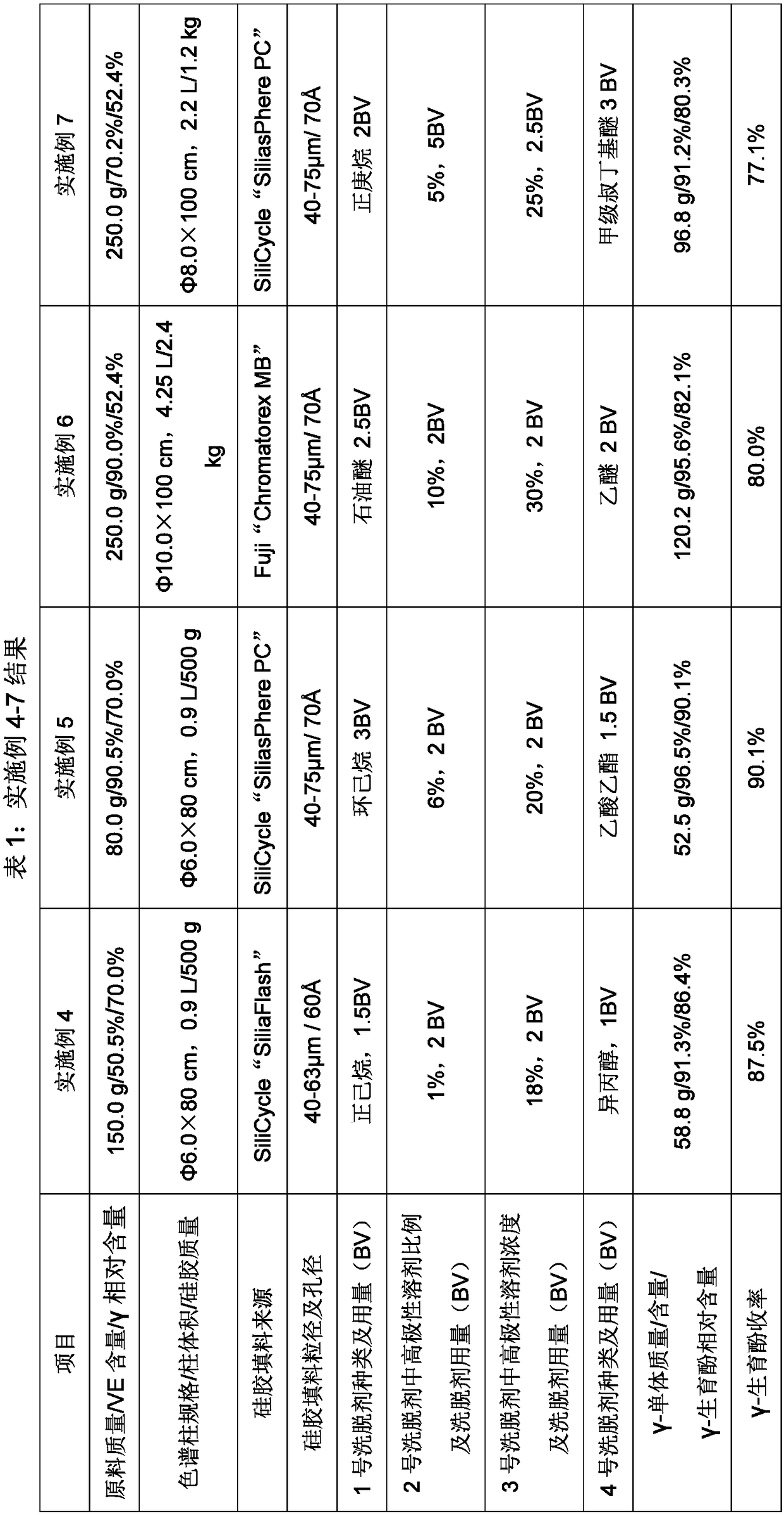

Embodiment 1

[0035] ·Instrument: medium and low pressure preparative chromatography system (generally refers to pressure ≤ 2.0Mpa is medium and low pressure, Suzhou Lisui Technology Co., Ltd., EZ Purifier 100 / 200 medium pressure purification system), stainless steel column Fill 300.0g of "Chromatorex MB" series of non-bonded spherical silica gel produced by Fuji, with a column volume of 650ml (1BV), a particle size of 40-75μm, and a pore size of Add a small amount of cyclohexane, fill it into the chromatography column, and the column volume is regarded as 550ml (ie 1BV=550ml). Use 3 times the cyclohexane (1650ml) of chromatographic column volume to elute and compact the equilibrated chromatographic column, then 75.0g mixed tocopherol concentrate (total tocopherol content 50.5%, wherein γ-tocopherol relative content 63.8%) (The mixed tocopherol raw material comes from Xinchang Pharmaceutical Factory) and 75mL cyclohexane to dissolve and load the sample, continue to elute with 2BV cyclohex...

Embodiment 2

[0040] Instrument: medium and low pressure preparative chromatography system (Suzhou Lisui Technology Co., Ltd., EZ Purifier 100 / 200 medium pressure purification system), stainless steel column Filled with 300.0g SiliCycle "SiliaFlash" series of non-bonded spherical silica gel, column volume 650ml (1BV), particle size 40-75μm, pore size

[0041] The chromatographic column was equilibrated according to the method of Example 1. After the chromatographic column in Example 1 was equilibrated, 50.0 g of mixed tocopherol concentrate (total tocopherol content 70.5%, wherein the relative content of γ-tocopherol was 63.8%) was added to 100 ml of n-heptane, dissolved and loaded. After loading the sample, continue to elute with 1.5BV of n-heptane hexane, collect eluent I and eluent II in sections; 2BV 30% first-class tert-butyl ether and n-heptane mixed solution elution collected eluent II and eluent III; then eluted with 2BV first-class tert-butyl ether to obtain eluent IV, and fina...

Embodiment 3

[0044] Instrument: medium and low pressure preparative chromatography system (Suzhou Lisui Technology Co., Ltd., EZ Purifier 100 / 200 medium pressure purification system), stainless steel column Filled with 300.0g SiliCycle "SiliaFlash" series of non-bonded spherical silica gel, column volume 650ml (1BV), particle size 40-75μm, pore size

[0045] The chromatographic column was equilibrated according to the method of Example 1. After equilibrating the chromatographic column according to the steps in Example 1, add 30.0 g of mixed tocopherol concentrate (total tocopherol content 90.5%, wherein the relative content of γ-tocopherol is 70.0%) into 15 ml of n-hexane, dissolve and load the sample. After loading the sample, continue to elute with 1.5BV of n-hexane, and collect eluent I and eluent II in sections; The mixed solution is eluted to collect eluent II and eluent III; then eluted with 2BV of ether to obtain eluent IV, and finally equilibrated with 2BV of n-hexane, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com