Preparation method of high-cycle lithium storage type carbon material

A technology for lithium batteries and carbon materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor lithium storage performance, and achieve the effects of improving electrical conductivity, improving structural stability, and improving lithium storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

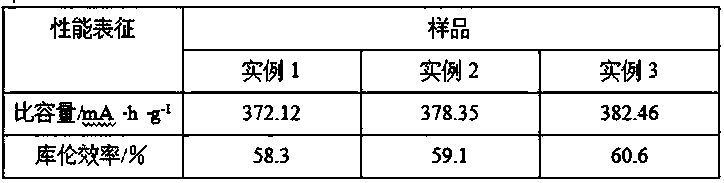

Examples

Embodiment Construction

[0017] Wash the soybean stalks and let them dry naturally at room temperature, collect the dried soybean stalks, wash and dry the beef bones, mix the dried soybean straws with the dried beef bones at a mass ratio of 1:1, and use a pulverizer Crush, grind and pass through a 45-60 mesh sieve to obtain mixed grinding powder. Collect the mixed grinding powder and place it in a muffle furnace. After exhausting the air with nitrogen, slowly raise the temperature to 850-900 °C at 5°C / min for carbonization treatment for 10- 15min, after the carbonization is completed, let it stand and cool to room temperature to prepare carbonized particles; then according to the mass ratio of 1:5, stir and mix the carbonized particles with a mass concentration of 15% zinc chloride solution, then filter and collect the filter cake, and filter The cake is placed in a high-temperature pyrolysis furnace, activated at 100-120°C for 10-15 minutes, then left to cool to room temperature, ground and passed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com