Preparation method of two-dimensional porous boron-nitrogen double-doping carbon nanomaterial and application thereof

A carbon nanomaterial, double doping technology, applied in nanocarbon, hybrid capacitor electrodes, etc., to achieve the effect of low equipment requirements, high electrochemical stability, and high specific capacitance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Mix 10g of urea and 1ml of 1-butyl-3-methylimidazolium tetrafluoroborate and grind them. After fully grinding, put the evenly ground sample into a crucible and place it in a muffle furnace at 2°C. / min heating rate to 550 ° C, and calcined at this temperature for 3 hours;

[0025] (2) the graphitized boron-nitrogen-doped carbon material (B-g-CN) prepared in step (1) 550 ) was dispersed in 40 mL of aqueous glucose solution with a concentration of 0.0325 g / mL, and was uniformly ultrasonicated, poured into a reaction kettle, and reacted in a constant temperature oven at 170° C. for 4 hours.

[0026] (3) The glucose-wrapped graphitized boron-nitrogen double-doped carbon material (B-g-CN) prepared in step (2) 550 / glu) was placed in a tube furnace, and calcined at 800 °C for 1 h at a heating rate of 3 °C / min in a high-temperature argon atmosphere to obtain a two-dimensional porous boron-nitrogen double-doped carbon nanomaterial.

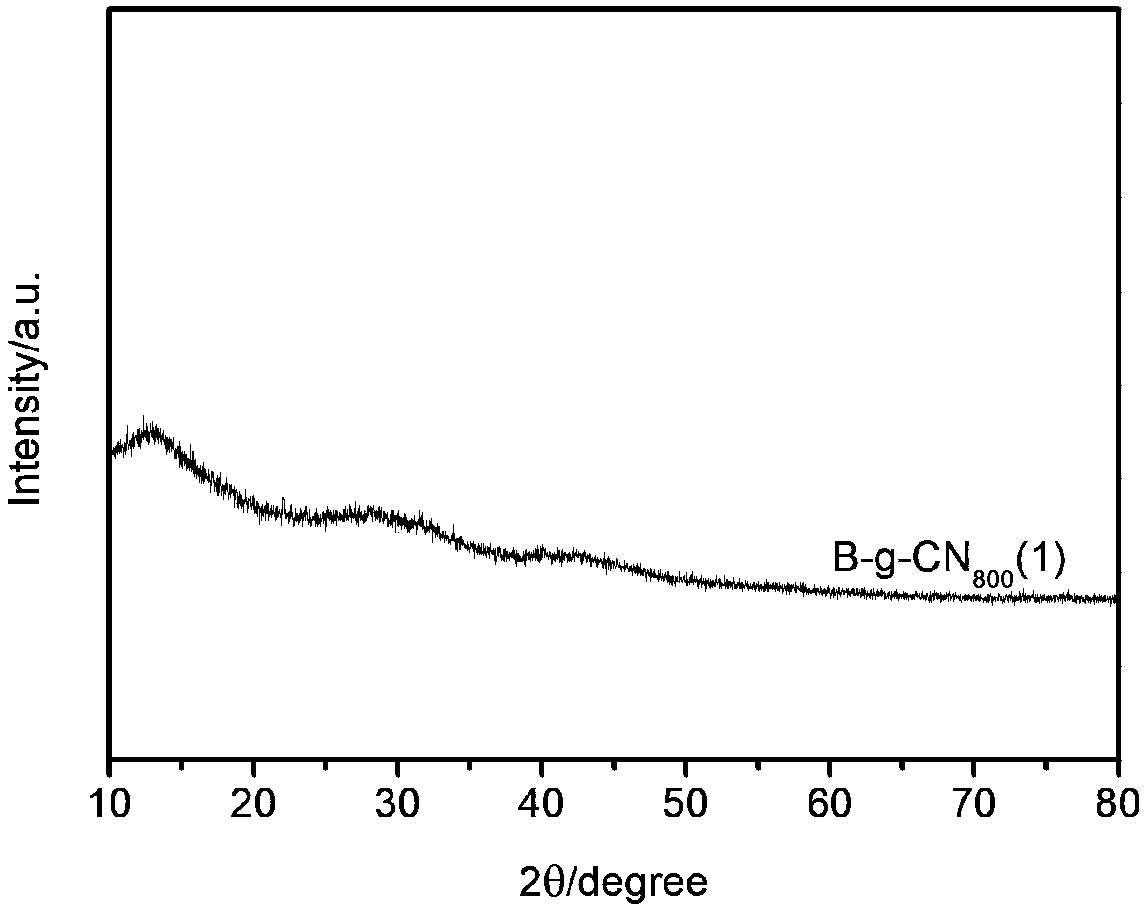

[0027] figure 1 It is a TEM image of ...

Embodiment 2

[0031] (1) Mix 10g of urea with 0.5ml of 1-butyl-3-methylimidazolium tetrafluoroborate and grind it. After fully grinding, put the evenly ground sample into a crucible in a muffle furnace. The heating rate of ℃ / min is raised to 550℃, and calcined at this temperature for 3h;

[0032] (2) the graphitized boron-nitrogen-doped carbon material (B-g-CN) prepared in step (1) 550 ) was dispersed in 40 mL of aqueous glucose solution with a concentration of 0.0325 g / mL, and was uniformly ultrasonicated, poured into a reaction kettle, and reacted in a constant temperature oven at 170° C. for 4 hours.

[0033] (3) The glucose-wrapped graphitized boron-nitrogen double-doped carbon material (B-g-CN) prepared in step (2) 550 / glu) was placed in a tube furnace, and calcined at 800 °C for 1 h at a heating rate of 3 °C / min in a high-temperature argon atmosphere to obtain a two-dimensional porous boron-nitrogen double-doped carbon nanomaterial.

Embodiment 3

[0035] (1) Mix 10g of urea with 1.5ml of 1-butyl-3-methylimidazolium tetrafluoroborate and grind it. After fully grinding, put the evenly ground sample into a crucible in a muffle furnace. The heating rate of ℃ / min is raised to 550℃, and calcined at this temperature for 3h;

[0036] (2) the graphitized boron-nitrogen-doped carbon material (B-g-CN) prepared in step (1) 550 ) was dispersed in 40 mL of aqueous glucose solution with a concentration of 0.0325 g / mL, and was uniformly ultrasonicated, poured into a reaction kettle, and reacted in a constant temperature oven at 170° C. for 4 hours.

[0037] (3) The glucose-wrapped graphitized boron-nitrogen double-doped carbon material (B-g-CN) prepared in step (2) 550 / glu) was placed in a tube furnace, and calcined at 800 °C for 1 h at a heating rate of 3 °C / min in a high-temperature argon atmosphere to obtain a two-dimensional porous boron-nitrogen double-doped carbon nanomaterial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com