Preparation method of modified chitosan-based bionic fish baits

A technology of bionic fishing bait and chitosan, which is applied in the fields of artificial fish bait, fishing, animal husbandry, etc., can solve the problems of failing to meet market requirements, no biodegradable function, low strength, etc., and achieve strength improvement, dispersibility and mutual The effect of reducing the effect and improving the cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

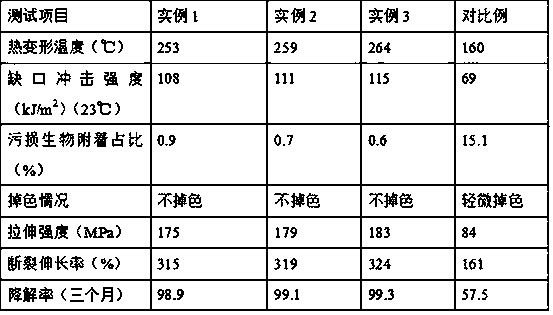

Examples

example 1

[0022]Weigh 10g of salicylic acid powder into a beaker with 32mL of diethyl ether, add 4mL of boron trifluoride diethyl ether to mix, and stir and react at a temperature of 65°C for 1h to obtain a jelly. After cooling to room temperature, use Mass fraction is 10% saline washing jelly 4 times, continue to add 45mL ethyl acetate in the jelly after washing, mix and stir reaction 21min, obtain self-made dimer salicylate crystal; 3:1 Mix cornstarch and deionized water in a beaker, mix and stir for 27min at a temperature of 55°C to obtain gelatinized cornstarch, then add persulfuric acid of 2% gelatinized cornstarch mass to gelatinized cornstarch ammonium and gelatinized cornstarch mass 3% acrylic acid, continue to insulate and mix and stir for 1 hour to obtain pretreated cornstarch, mix the pretreated starch and self-made dimeric salicylic acid lactone crystals in a mass ratio of 5:1, and Stir at a temperature of 35°C for 16 minutes to obtain modified cornstarch; weigh 45g of shrim...

example 2

[0024] Weigh 11g of salicylic acid powder into a beaker with 37mL of diethyl ether, add 5mL of boron trifluoride diethyl ether to mix, and stir the reaction at 67°C for 1.5h to obtain a jelly. After cooling to room temperature, Wash the jelly 5 times with 10% saline, continue to add 47 mL of ethyl acetate to the washed jelly, mix and stir for 22 minutes to obtain self-made dimeric salicylate crystals; Mix cornstarch and deionized water at a ratio of 3:1 and put them in a beaker, mix and stir for 28 minutes at a temperature of 57°C to obtain gelatinized cornstarch, and then add gelatinized cornstarch 2% of gelatinized cornstarch to the gelatinized cornstarch Ammonium sulfate and 3% acrylic acid of gelatinized cornstarch mass, continue to insulate and mix and stir for 1.5h to obtain pretreated cornstarch, mix the pretreated starch and self-made dimeric salicylate crystals at a mass ratio of 5:1, Stir at 40°C for 18 minutes to obtain modified cornstarch; weigh 53 g of shrimp shel...

example 3

[0026] Weigh 12g of salicylic acid powder into a beaker with 40mL of diethyl ether, add 6mL of boron trifluoride diethyl ether to mix, and stir the reaction at a temperature of 70°C for 2h to obtain a jelly. After cooling to room temperature, use Mass fraction is 10% saline washing jelly 6 times, continue to add 50mL ethyl acetate in the jelly after washing, mix and stir reaction 24min, obtain self-made dimer salicylate crystal; 3:1 Mix cornstarch and deionized water in a beaker, mix and stir for 30 minutes at a temperature of 60°C to obtain gelatinized cornstarch, then add persulfuric acid of 2% gelatinized cornstarch mass to gelatinized cornstarch ammonium and gelatinized cornstarch quality 3% acrylic acid, continue to insulate and mix and stir for 2 hours to obtain pretreated cornstarch, mix the pretreated starch and self-made dimeric salicylic acid lactone crystals in a mass ratio of 5:1, and Stir at 45°C for 20 minutes to obtain modified cornstarch; weigh 60g of shrimp sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com