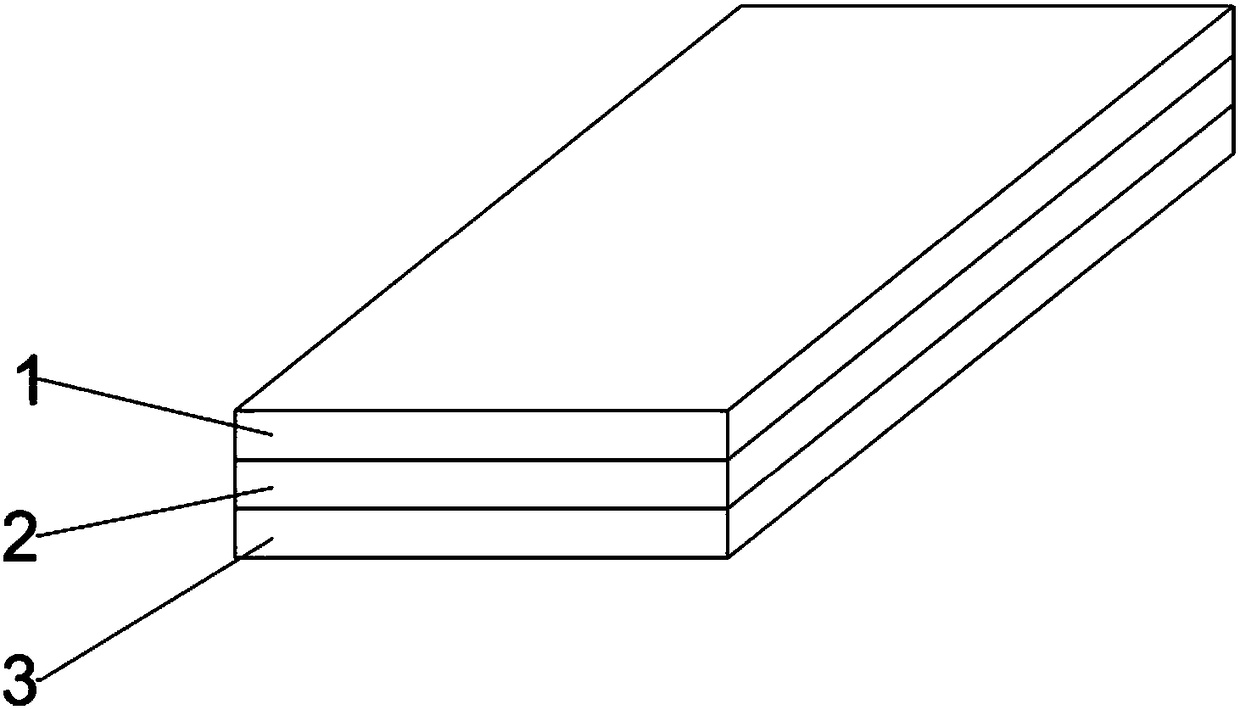

UV visbreaking composition, UV visbreaking film, and production method of film

A composition and mucous membrane technology, applied in the direction of non-polymer organic compound adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of incomplete performance stability, easy to absorb dust, easy to generate static electricity, etc. Problems, to achieve excellent anti-static, easy to peel, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0071] 40g acrylic pressure-sensitive adhesive resin (manufacturer: Shanghai Toyo Ink Manufacturing Co., Ltd., model: STS0123OP), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-5805W), 1g Cross-linking agent (manufacturer: Bayer, Germany, model: N3390), 3g antistatic agent (manufacturer: Shenzhen Huigao Gold Standard Technology Co., Ltd., model: GW-2008), 0.8g dispersant (manufacturer: Bicker, Germany company, model: BYK-170), 0.2g leveling agent (manufacturer: BYK, Germany, model: BYK-333), 5g of 2,4,6-(trimethylbenzoyl)-diphenyl Phosphine oxide (TPO), 30 g of butanone.

[0072] Wherein, the average molecular weight of the STS0123OP is 600,000, the solid content is 25%, and the viscosity is 10,000 cps. The UX-5805W is an aliphatic urethane acrylate oligomer.

Embodiment 2

[0074] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0075] 40g acrylic pressure-sensitive adhesive resin (manufacturer: Shanghai Toyo Ink Manufacturing Co., Ltd., model: STS0123OP), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-5805W), 1g Crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 2g nano-graphite powder (manufacturer: Shanghai Youmo Composite Materials Co., Ltd.), 0.8g dispersant (manufacturer: BYK, Germany, model: BYK- 164), 0.2g leveling agent (manufacturer: BYK, Germany, model: BYK-306), 5g of 2,4,6-(trimethylbenzoyl)-diphenylphosphine oxide (TPO), 31 g of butanone.

[0076] Wherein, the particle size range of the nano-graphite powder is 50-100nm.

Embodiment 3

[0078] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0079]40g acrylic pressure-sensitive adhesive resin (manufacturer: Shanghai Toyo Ink Manufacturing Co., Ltd., model: STS0123OP), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-5805W), 1g Crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 0.2g nano-graphene (manufacturer: Hefei Microcrystalline Material Technology Co., Ltd.), 0.8g dispersant (manufacturer: BYK, Germany, model: BYK -180), 0.2g leveling agent (manufacturer: BYK, Germany, model: BYK-390), 5g of 2,4,6-(trimethylbenzoyl)-diphenylphosphine oxide (TPO) , 32.8 g of butanone.

[0080] Wherein, the particle size range of the nano-graphene is 5-20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com