Preparation method of 1-palmitate-2-oleate-3-stearate triglyceride fat

A technology of oleic acid triglyceride and triglyceride fat, which is applied in the field of preparation of 1-palmitic acid-2-oleic acid-3-stearic acid triglyceride fat, can solve the problem of many reaction by-products and accelerated fat system Oxidation or, pollution and other problems, to achieve the effect of less by-products, high anti-frost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

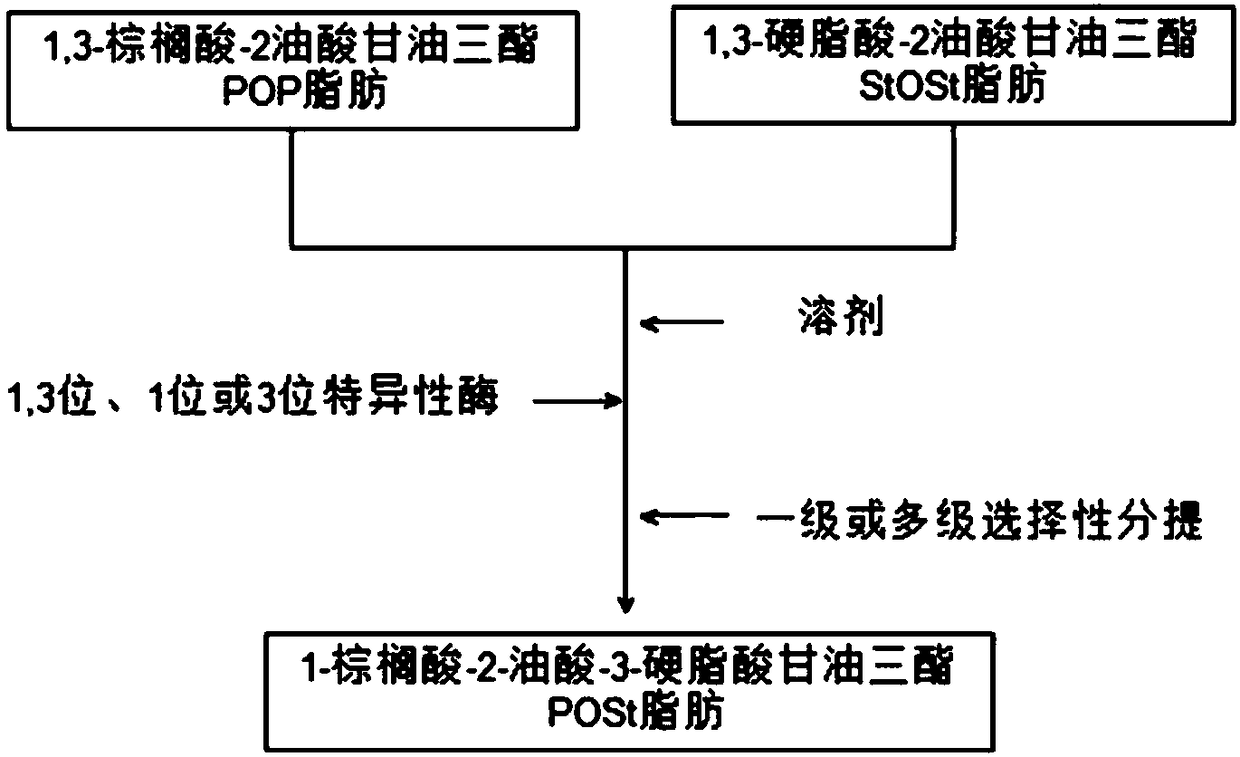

Method used

Image

Examples

Embodiment 1

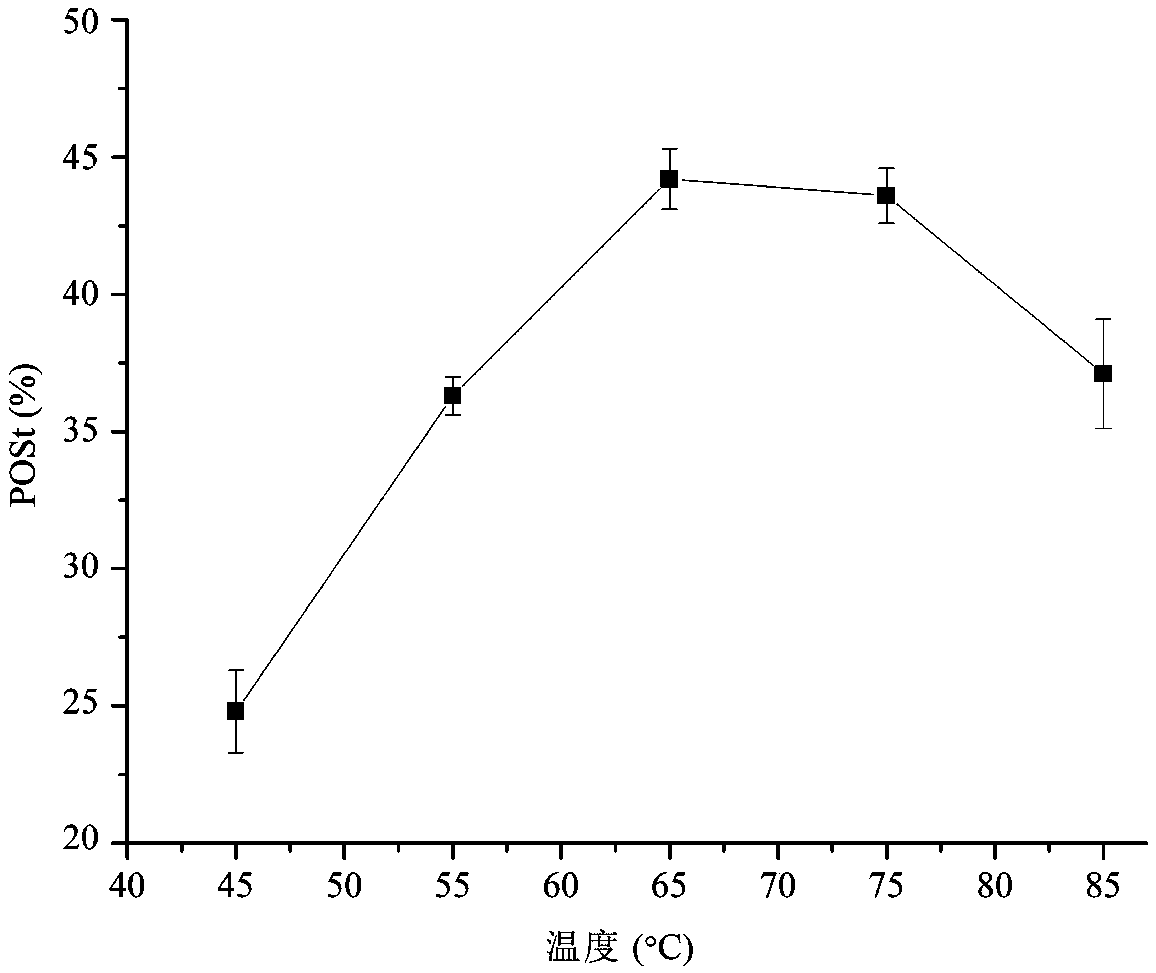

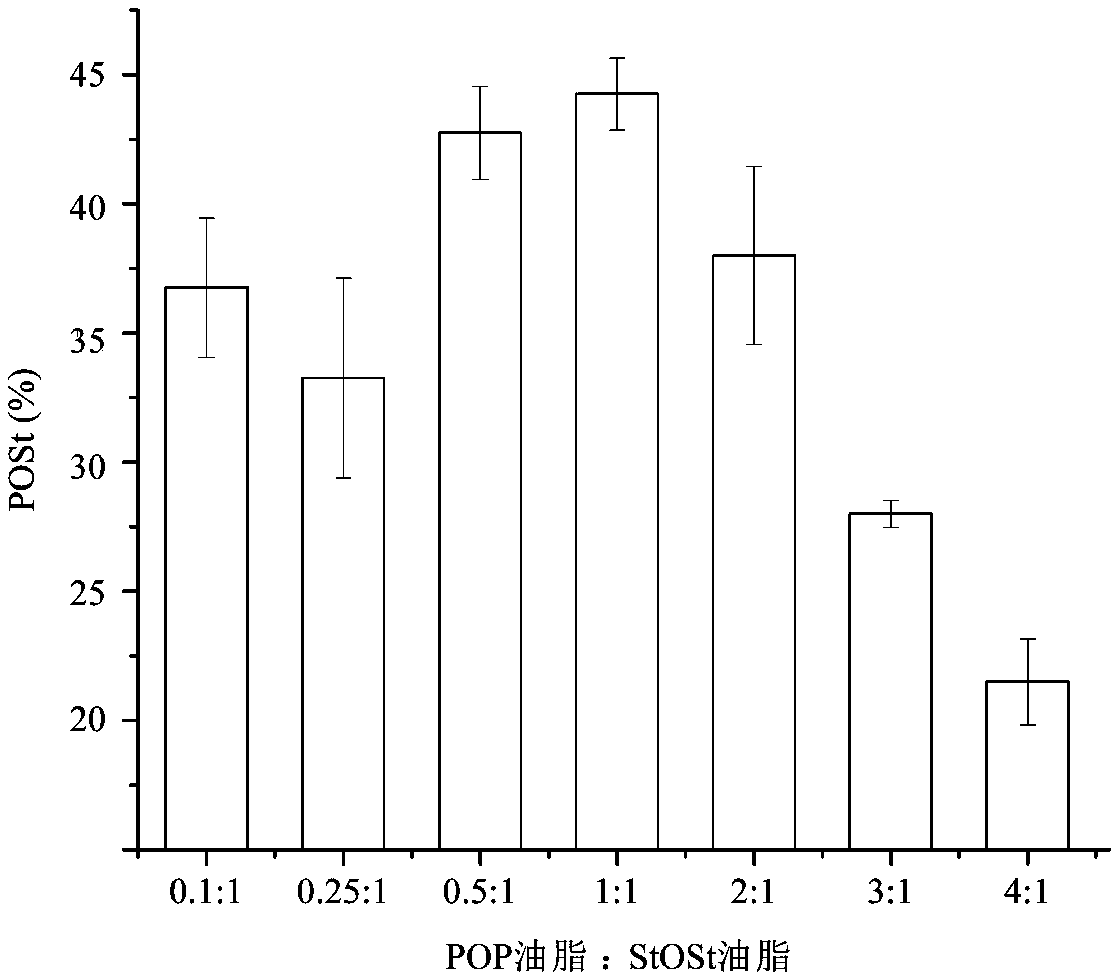

[0030] Using palm oil intermediate fraction and mango kernel oil stearin as raw materials, under the conditions of transesterification reaction time of 4 to 6 hours and enzyme addition of 0.5%, the reaction temperature, substrate mixing ratio and enzyme concentration of transesterification were optimized. types, the results are as follows figure 2 , image 3 with Figure 4 shown.

[0031] according to figure 2 It can be seen that when the transesterification temperature reaches 65-75°C, the content of POSt in the product is the highest, reaching 43.6%-44.2%, and the content of POSt will decrease significantly if the reaction temperature is lower than 65°C or higher than 75°C. Among them, when the reaction temperature is low, the conversion of POP and StOSt to POSt is relatively slow; and when the reaction temperature is too high, the problem of acyl transfer is prone to occur, that is, undesirable triglycerides such as PStO are generated.

[0032] according to image 3 ...

Embodiment 2

[0036] After obtaining the transesterification product, acetone, methylpentane, acetonitrile, methanol, and ethanol were used to fractionate and enrich POSt, analyze the correlation between the solvent polarity and the physical and chemical indicators of the product, and perform curve fitting by multiple linear regression. Combined with the step-by-step elimination method, there is a significant relationship between the solvent polarity and the sliding melting point (P2 =0.93, where y is the rate of change of the sliding melting point of the resulting POSt fat, and x is the polarity value of the solvent, i.e. the Log P value).

[0037]According to this formula, for solvents with a Log P value less than 3.20, symmetrical triglycerides can be selectively enriched, and the POSt content can be as high as 68.0% to 71.0% after fractionation of transesterified products.

Embodiment 3

[0039] Dissolve 50g of palm oil middle fraction (POP content 70.2%) and 50g mango kernel oil stearin (StOSt content 74.5%) in 600mL methyl pentane, add 0.2% Lipzyme TL IM enzyme, react at 75°C After 5.5h, the solvent was recovered by evaporation to complete the esterification reaction. Mix 90.6g of the reaction product with 400mL of methylpentane evenly, lower the temperature of the mixed oil to 18°C at a stirring speed of 39r / min and a cooling rate of 2.6°C / min, crystallize at constant temperature for 6 hours, and filter under reduced pressure After separating, evaporating and recovering the solvent, first-grade stearin was obtained; then 77.6g of first-grade stearin and 400mL methyl pentane were evenly mixed, and the temperature of the reaction product was cooled at a stirring speed of 12r / min at a cooling rate of 1.5°C / min. The temperature was lowered to 2°C, crystallized at constant temperature for 2.5 hours, separated by suction filtration under reduced pressure, and ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com