Iodine-containing nanoparticles for tumor-targeted CT imaging and preparation method thereof

A tumor-targeting, nanoparticle-based technology, applied in the field of preparation of iodine-containing nanoparticle contrast agents, to achieve the effects of strong controllability, long circulation time in the body, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

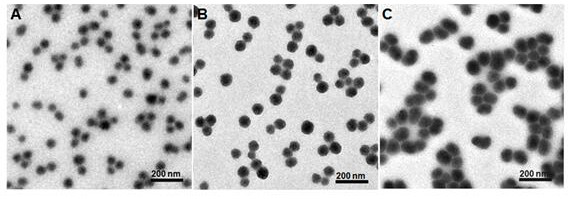

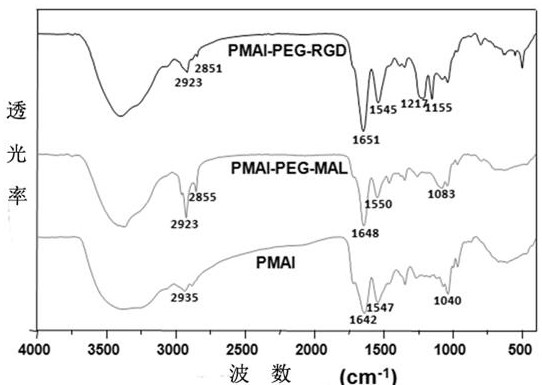

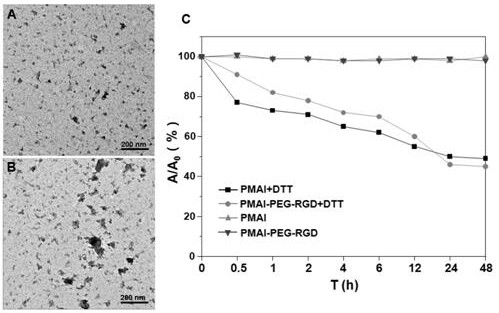

Embodiment 1

[0043] Step 1: Add 10.0 g of iopamidol (substance II) and 0.520 g of concentrated sulfuric acid to 40 mL of anhydrous N,N-dimethylacetamide, and then add the hydroxyl protecting agent 2,2-dimethylacetamide dropwise under stirring 6.40 mL of oxypropane was added to keep the reaction temperature at about 55 °C, and the reaction was stopped after stirring for 24 h. The reaction solution was neutralized with 3% sodium bicarbonate solution, and most of the solvent was removed by rotary evaporation to obtain a light yellow oil. 150 mL of distilled water was added to the oil, stirred at room temperature for 2 h, and then centrifuged to obtain a white solid, which was washed twice with distilled water to remove unreacted raw materials and impurities. The resulting product was dried in a vacuum oven at 50°C to obtain 8.0 g of crude product, which was separated and purified by silica gel column chromatography (dichloromethane:methanol=15:1) to obtain 5 g of white compound III, the final...

Embodiment 2

[0055] Step 1: Add 10.0 g of iopamidol (substance II) and 0.520 g of concentrated sulfuric acid to 40 mL of anhydrous N,N-dimethylacetamide, then add 2,2-dimethoxypropane dropwise under stirring 6.40 mL, the reaction temperature was maintained at about 55 °C, and the reaction was stopped after stirring for 24 h. The reaction solution was neutralized with 3% sodium bicarbonate solution, and most of the solvent was removed by rotary evaporation to obtain a light yellow oil. 150 mL of distilled water was added to the oil, stirred at room temperature for 2 h, and then centrifuged to obtain a white solid, which was washed twice with distilled water to remove unreacted raw materials and impurities. The resulting product was dried in a vacuum oven at 50°C to obtain 8.0 g of crude product, which was separated and purified by silica gel column chromatography (dichloromethane:methanol=15:1) to obtain 5 g of white compound III, the final yield was 45.6%. product by 1 H-NMR, MS and FTI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com