Functionalized high-density chromatographic substrate, preparation method thereof and application thereof

A high-density layer and functionalization technology, which is applied in the preparation method of peptides, chemical instruments and methods, separation methods, etc., can solve the problem of limiting the adsorption capacity of chromatographic substrates and improving adsorption specificity, reducing the amount of ligand coupling, reaction Uncontrollable problems, to achieve the effect of low cost, low cost, and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

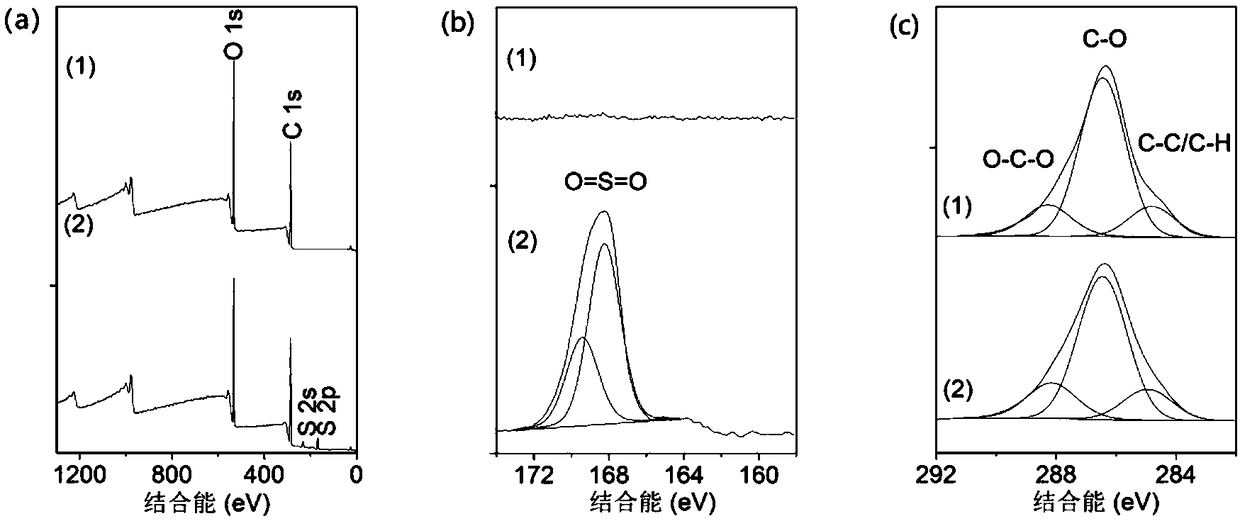

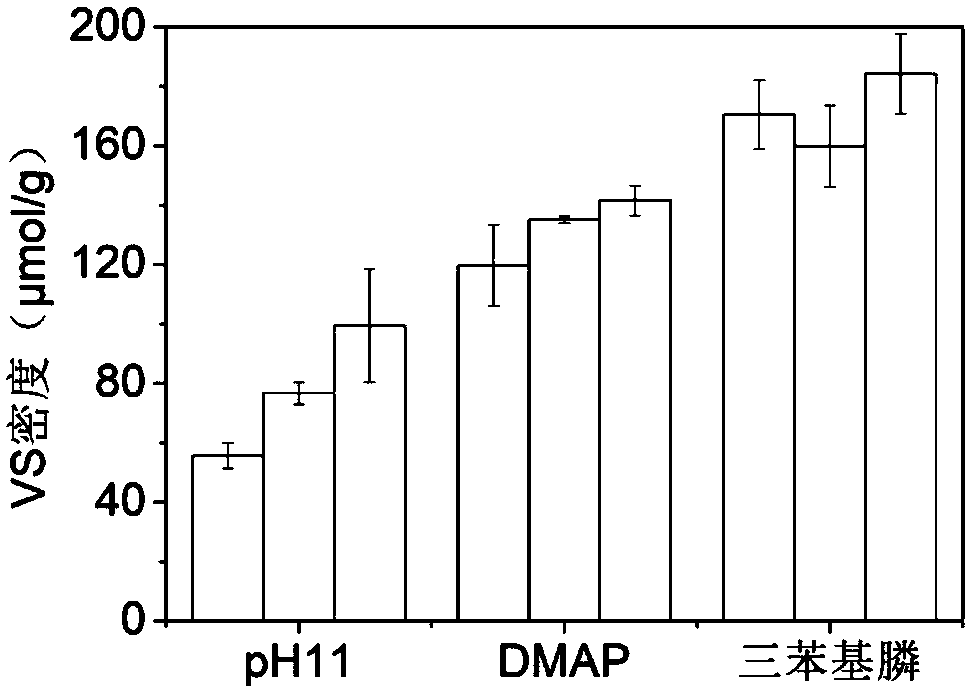

[0033] Take 0.3 g of agarose resin (Bastarose 6FF: highly cross-linked 6% agarose, average particle size 90 μm; Bogelong Biotechnology Co., Ltd.), filter it with suction and wash it well with acetonitrile to remove the water in it, add 1 mL containing 4-bis A solution of 10% (v / v) divinyl sulfone in acetonitrile of methylaminopyridine, wherein the molar ratio of 4-dimethylaminopyridine to divinyl sulfone is 1:10, reacted at 25°C for 12h, pumped out after the reaction Filter and wash with acetonitrile to completely remove divinyl sulfone and catalyst residues to obtain VS functionalized agarose resin.

[0034] For the control group, 0.3 g of agarose resin was added to 1 mL of carbonate buffer solution (0.5 M, pH 11) containing 10% (v / v) divinyl sulfone and 10% acetone, and reacted for 12 h at 25°C. After the end, filter with suction and wash with acetonitrile to completely remove divinyl sulfone residues. Take quantitative functionalized agarose resin, add excess cysteine so...

Embodiment 2

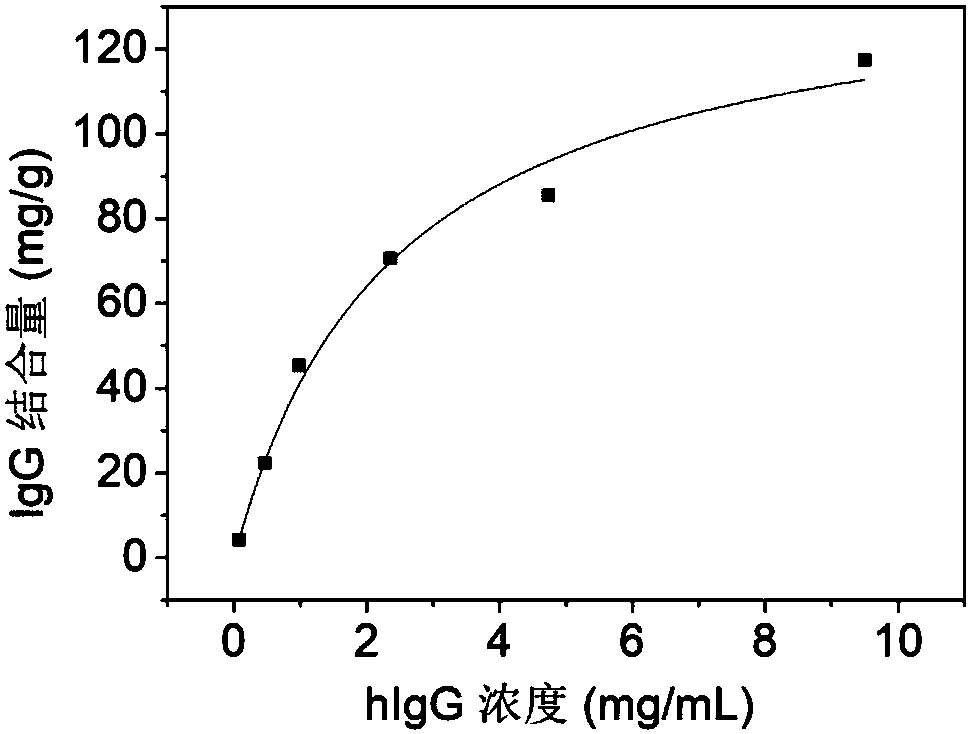

[0036]Take 0.3 g of agarose resin (Bastarose 6FF: highly cross-linked 6% agarose, with an average particle size of 90 μm; Borgron Biotechnology Co., Ltd.), filter it with suction and wash it with acetonitrile to remove water, add 1 mL containing triphenyl 10% (v / v) acetonitrile solution of divinyl sulfone of phosphine, wherein the molar ratio of triphenyl phosphine to divinyl sulfone is 1:10, react at 25°C for 1 h, after the reaction is completed, suction filtration and wash with acetonitrile Divinyl sulfone and catalyst residues were thoroughly removed to obtain VS functionalized agarose resin.

[0037] In the control group, 0.3 g of agarose resin was added to 1 mL of carbonate buffer (0.5 M, pH 11) containing 10% (v / v) divinyl sulfone and 10% acetone, and the reaction was carried out at 25 °C for 12 h. After the end, suction filtration and washing with acetonitrile thoroughly remove the residual divinyl sulfone. Take a quantitative functionalized agarose resin, add an exces...

Embodiment 3

[0039] Take 0.3 g of agarose resin (Bastarose 6FF: highly cross-linked 6% agarose, with an average particle size of 90 μm; Borgron Biotechnology Co., Ltd.), filter it with suction and wash it with acetonitrile to remove water, add 1 mL containing triphenyl 10% (v / v) acetonitrile solution of phosphine in divinyl sulfone, wherein the molar ratio of triphenyl phosphine and divinyl sulfone is 1:10, react at 25°C for 2h, after the reaction, suction filtration and wash with acetonitrile Divinyl sulfone and catalyst residues were thoroughly removed to obtain VS functionalized agarose resin.

[0040] In the control group, 0.3 g of agarose resin was added to 1 mL of carbonate buffer (0.5 M, pH 11) containing 10% (v / v) divinyl sulfone and 10% acetone, and the reaction was carried out at 25 °C for 12 h. After the end, suction filtration and washing with acetonitrile thoroughly remove the residual divinyl sulfone. Take a quantitative functionalized agarose resin, add an excess of cystein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com