Ex-situ pre-reduction and passivation treatment method for acetylene pre-hydrogenation catalyst

A hydrogenation catalyst and passivation treatment technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. Affecting problems such as normal driving, achieving high catalytic activity and selectivity, easy storage and transportation, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

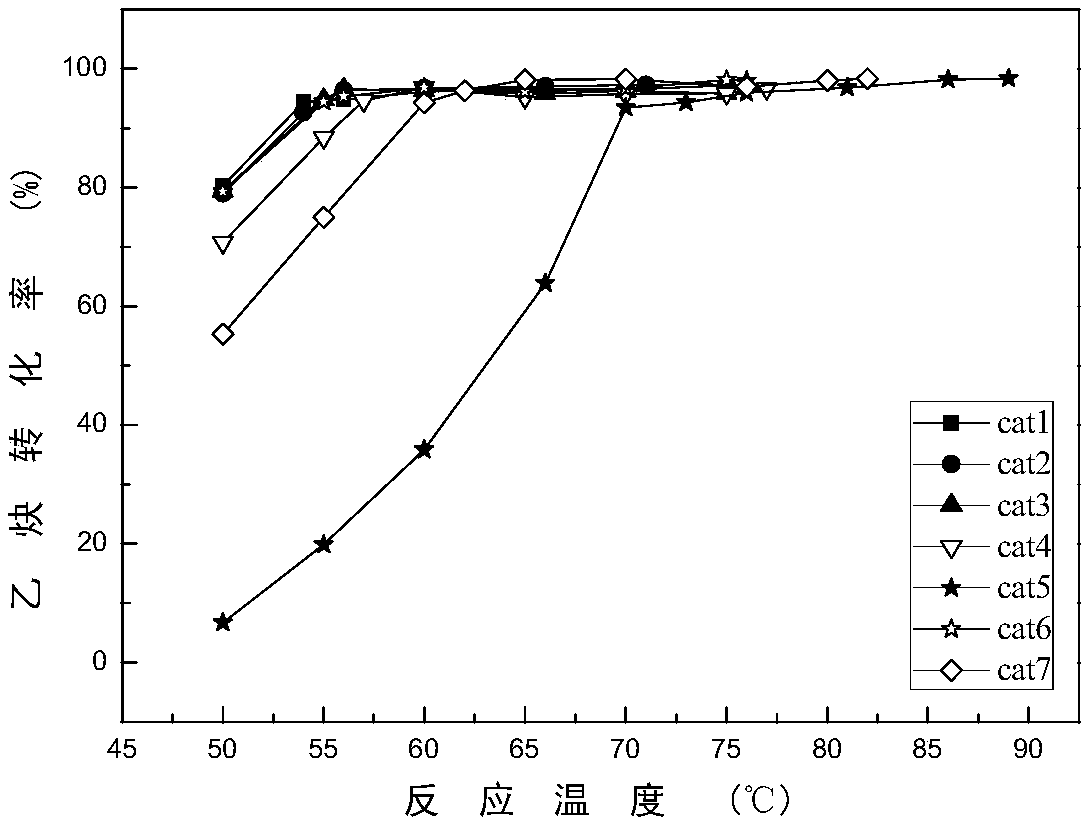

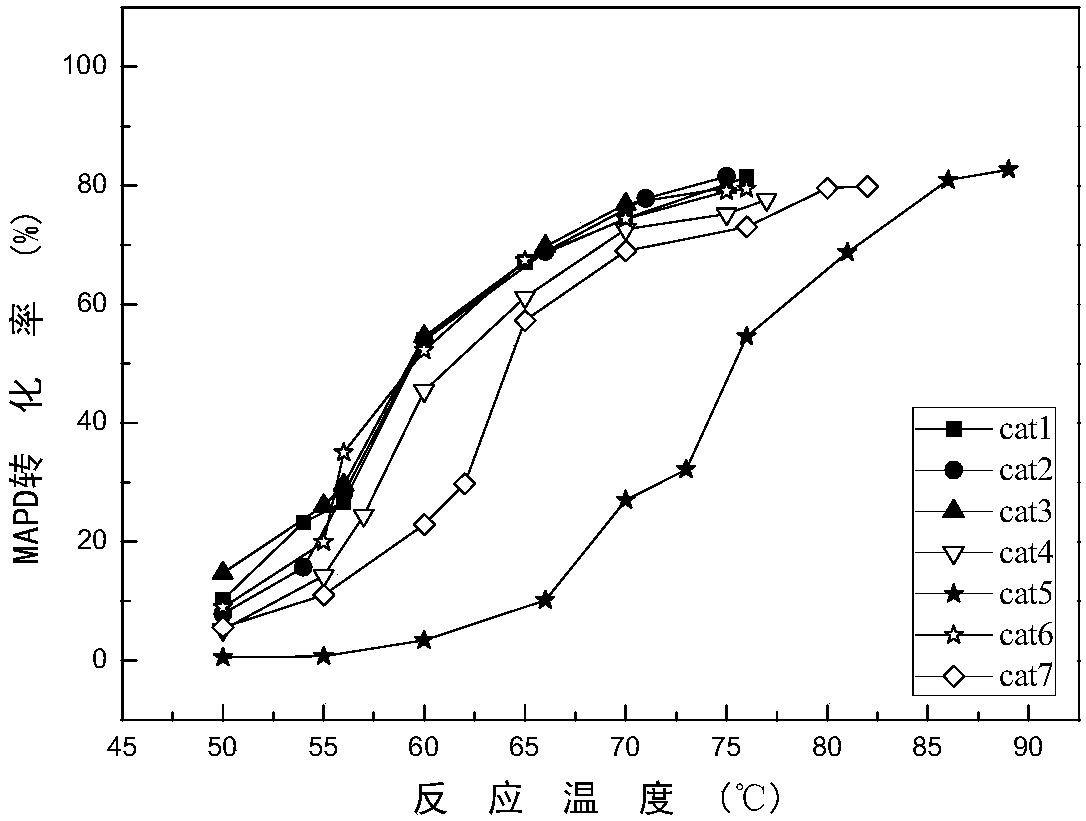

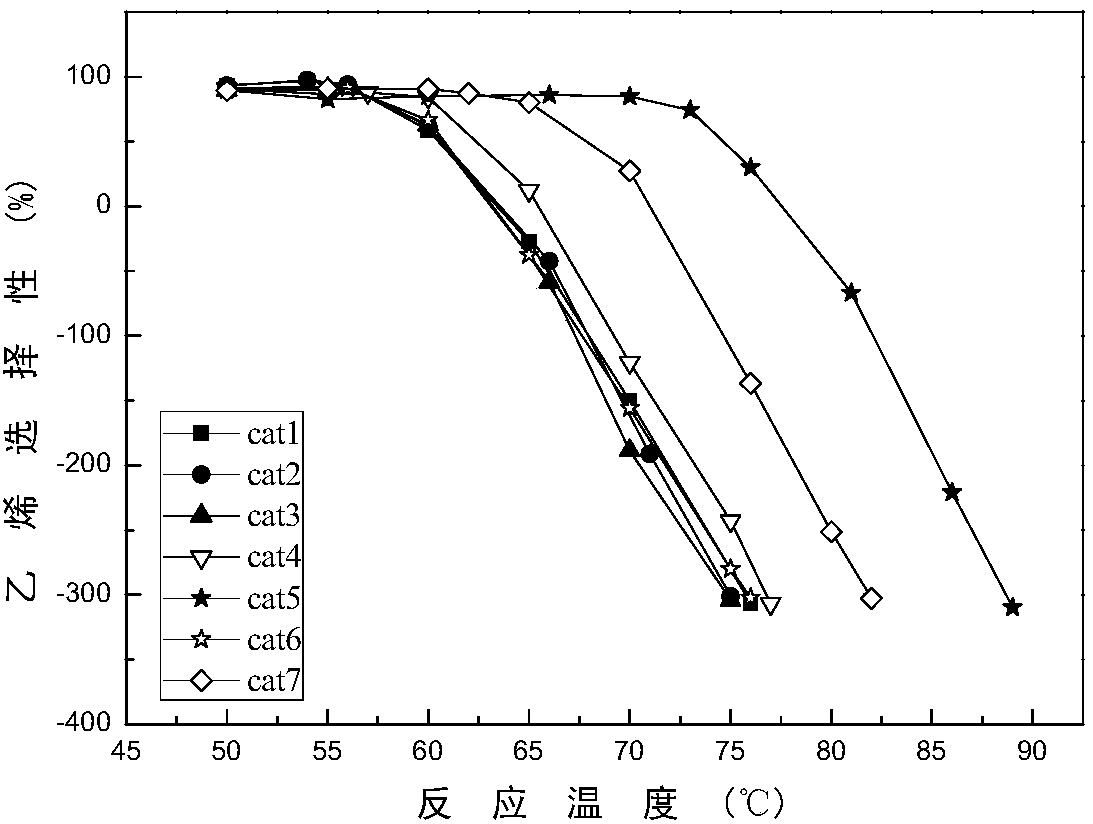

Embodiment 1

[0034] Weigh 1g 20-40 mesh Pd-Ag / Al 2 o 3 The catalyst (cat0) was loaded into the reactor for pre-reduction and passivation treatment. At normal pressure, the volumetric space velocity is 3000h -1 of pure H 2 Under the conditions, the temperature was programmed at a rate of 1 °C / min to 130 °C for 3 h, and the H 2 Switch to N 2 , turn off the power supply of the heating mantle and cool down to 50°C to start passivation treatment, and turn on N 2 and 5%O 2 , 95% N 2 passivation of the gas mixture, by adjusting the N2 and the flow rate of mixed gas to adjust the concentration of passivation gas, O 2 The molar concentration was gradually increased from 0.61% to 5.0% through eight gradients, and each concentration was maintained for 30 minutes. After that, the volumetric space velocity is 3000h -1 The air continued to passivate for 10h, and the catalyst cat1 was obtained;

[0035] The molar concentration gradient of oxygen is: 0.61%, 0.97%, 1.27%, 1.75%, 2.13%, 2.42%, 3.2...

Embodiment 2

[0037] The specific implementation process is roughly the same as in Example 1, except that the passivation temperature is constant at 50° C., and the obtained passivated catalyst is cat2.

Embodiment 3

[0039] The specific implementation process is roughly the same as in Example 1, except that the passivation temperature is constant at 30° C., and the obtained passivated catalyst is cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com