Y2O3 nano powder and preparation method thereof

A nano-powder, micron-scale technology, applied in nanotechnology, chemical instruments and methods, rare earth metal compounds, etc., can solve the problems of harsh reaction conditions, poor chemical uniformity, wide particle size distribution, etc., and achieve a simple preparation method. Easy to implement, good industrial application prospects, and the effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

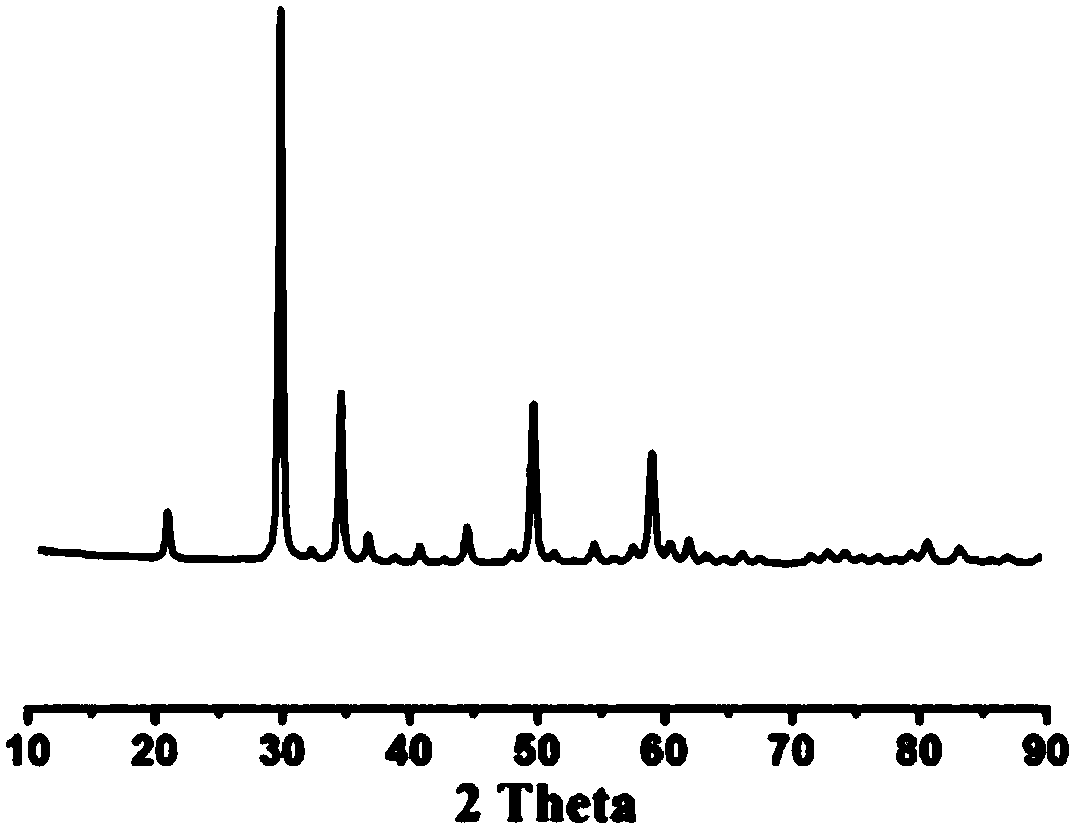

[0029] A certain mass of micron-scale (4N)Y 2 o 3 The powder (purity 99.99%) is heated and completely dissolved in excess nitric acid (mass fraction is 65%), diluted with water to form 0.25mol / L Y(NO 3 ) 3 Clear solution, and micron (4N)Y 2 o 3 The ratio of dissolving with nitric acid (mass fraction is 65%) is a stoichiometric ratio of 2:3; while stirring, add 9g of citric acid and 0.806g of ethylene glycol to the above Y (NO 3 ) 3 After stirring until completely transparent, add ammonia (mass fraction 25%) to adjust the pH to 3 to obtain the mother liquor, and bathe in 80°C water for 2.5h to obtain a light yellow viscous precursor sol; dry the precursor sol at 180°C for 2h, Calcined at 600°C for 1 hour to obtain Y 2 o 3 Nano powder. The X-ray diffraction pattern of the nanometer yttrium oxide gained in the present embodiment 1 is as follows figure 1 as shown,figure 1 It shows that the precursor is calcined at 600°C for 1 hour to obtain a pure crystalline phase of nan...

Embodiment 2

[0031] A certain mass of micron-scale (4N)Y 2 o 3 The powder (purity 99.99%) is heated and completely dissolved in excess nitric acid (mass fraction is 65%), diluted with water to form 0.25mol / L Y(NO 3 ) 3 Clear solution, and micron (4N)Y 2 o 3 The ratio of dissolving with nitric acid (mass fraction is 65%) is a stoichiometric ratio of 2:3; while stirring, add 12g of citric acid and 0.906g of glycerol to the above Y (NO 3 ) 3 After stirring until completely transparent, ammonia water (25% by mass) was added to adjust the pH to 3 to obtain a mother liquor, and a light yellow viscous precursor sol was obtained in a 90°C water bath for 2 hours; the precursor sol was dried at 180°C for 2h, and 800°C ℃ calcined for 0.5h to obtain Y 2 o 3 Nano powder. Using a laser particle size analyzer, the average particle size of the yttrium oxide nanopowder obtained in Example 2 is about 45 nm.

Embodiment 3

[0033] A certain mass of micron-scale (4N)Y 2 o 3 The powder (purity 99.99%) is heated and completely dissolved in excess nitric acid (65% by mass fraction), diluted with water to form 0.2mol / L Y(NO 3 ) 3 Clear solution, and micron (4N)Y 2 o 3 The ratio of dissolving with nitric acid (mass fraction is 65%) is a stoichiometric ratio of 2:3; while stirring, add 7.2g of citric acid and 0.580g of PEG 400 to the above Y(NO 3 ) 3 After stirring until completely transparent, add ammonia (mass fraction 25%) to adjust the pH to 2.5 to obtain a mother solution, and bathe in 80°C for 2.5h to obtain a light yellow viscous precursor sol; dry the precursor sol at 240°C for 1.5h , calcined at 600°C for 1 h to obtain Y 2 o 3 Nano powder. Using a laser particle size analyzer, the average particle size of the yttrium oxide nanopowder obtained in Example 3 is about 48 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com