Electric control ion exchange coupling water electrolysis device and technology

A technology of ion exchange and anion exchange membrane, which is applied in the field of electrically controlled ion exchange coupling electrolysis water device, can solve the problems that have not been reported in theory and technology, and achieve the effect of high selectivity, simple operation and reversible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

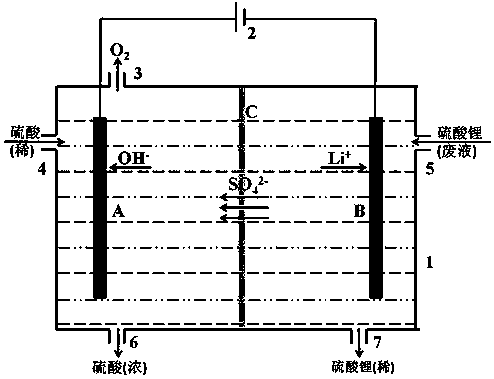

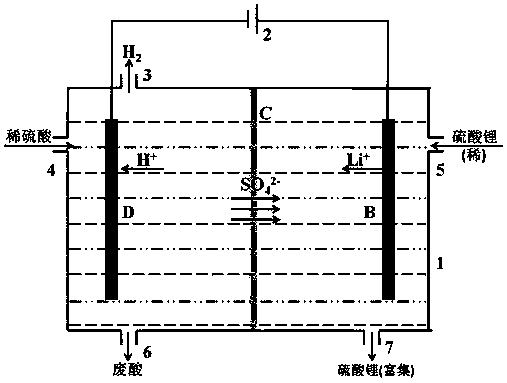

Embodiment 1

[0041] Treatment of lithium ions in recycled wastewater:

[0042] The process of lithium ion adsorption and oxygen evolution is as follows: figure 1 As shown, different functional electrodes are installed: electrocatalytic functional electrode A, electronically controlled ion exchange functional electrode B, anion exchange membrane C, the first liquid inlet 4, dilute sulfuric acid solution is injected into the left chamber, and the first liquid inlet 5 is opened , the right chamber is injected with lithium sulfate waste liquid to be treated. Then open the gas outlet 3 and connect the gas collection bag. A voltage is applied to adsorb lithium ions and discharge oxygen. After the adsorption is saturated, the first liquid outlet 6 is opened to collect the sulfuric acid solution with increased concentration (the discharge liquid can be reinjected into the adsorption system through the first liquid inlet 4 for recycling). Open the second liquid outlet 7 to discharge the lithium ...

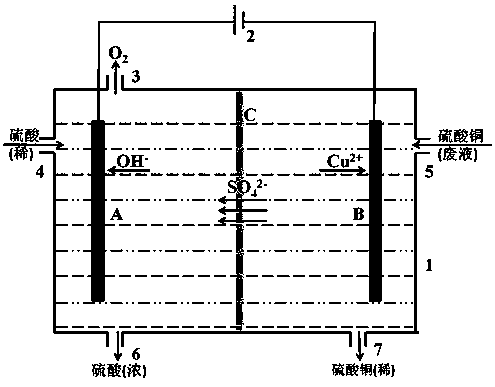

Embodiment 2

[0049] Treatment of copper ions in recycled wastewater:

[0050] The process of copper ion adsorption and oxygen evolution is as follows: image 3 As shown, install different functional electrodes: electrocatalytic functional electrode A, electronically controlled ion exchange functional electrode B, anion exchange membrane C, open the first liquid inlet 4, inject dilute sulfuric acid solution into the left chamber, and open the first liquid inlet 5. The right chamber is filled with copper sulfate waste liquid to be treated. Then open the gas outlet 3 and connect the gas collection bag. Apply voltage to adsorb copper ions and discharge oxygen. After the adsorption is saturated, the first liquid outlet 6 is opened to collect the sulfuric acid solution with increased concentration (the discharge liquid can be reinjected into the adsorption system through the first liquid inlet 4 for recycling). Open the second liquid outlet 7 to discharge the copper sulfate solution with redu...

Embodiment 3

[0057] Extraction and enrichment of lithium ions from salt lake brine:

[0058] The process of lithium ion adsorption and chlorine gas precipitation is as follows: Figure 5 As shown, install different functional electrodes: electrocatalytic functional electrode A, electronically controlled ion exchange functional electrode B, anion exchange membrane C, open the first liquid inlet 4, inject dilute hydrochloric acid solution into the left chamber, and open the first liquid inlet 5. The right chamber is filled with saline lake solution rich in lithium chloride. Then open the gas outlet 3 and connect the gas collection bag. A voltage is applied to adsorb lithium ions and discharge chlorine gas. After the adsorption is saturated, the first liquid outlet 6 is opened to collect the acid solution with increased concentration (the discharge liquid can be reinjected into the adsorption system through the first liquid inlet 4 for recycling). Open the second liquid outlet 7 to dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com