A kind of preparation method of low-loss amorphous magnetic powder core

A magnetic powder core, low-loss technology, applied in the field of preparation of low-loss amorphous magnetic powder core, can solve the problems of difficult to eliminate internal stress, high loss of amorphous magnetic powder core, poor high-frequency characteristics, etc. The effect of high crystal formation ability and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

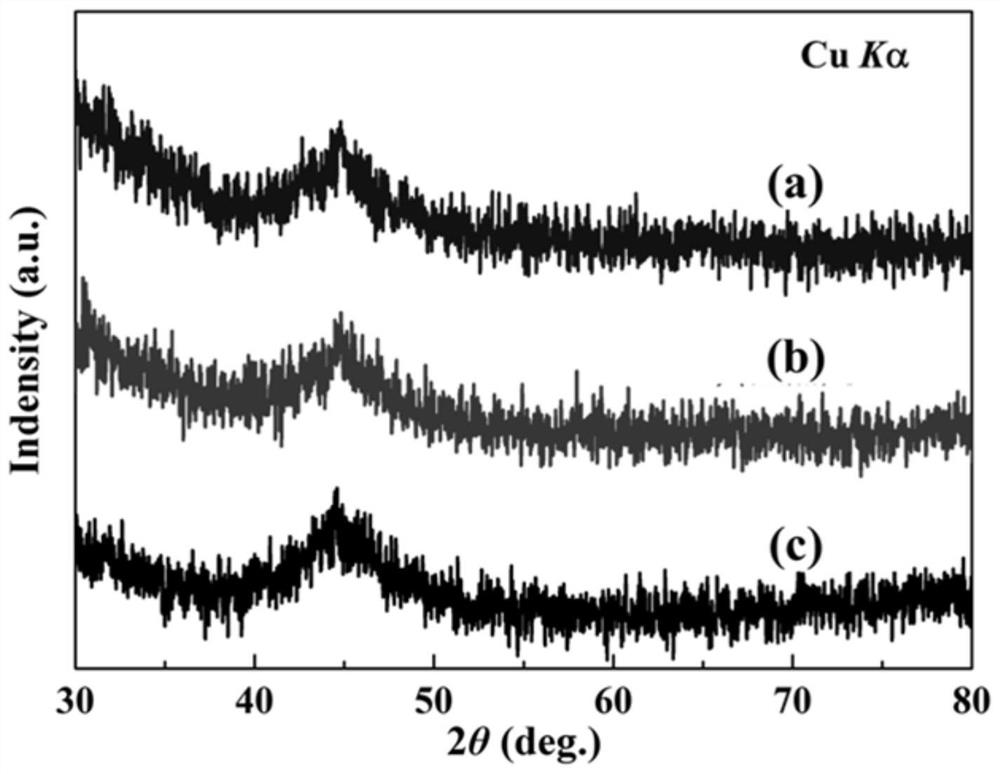

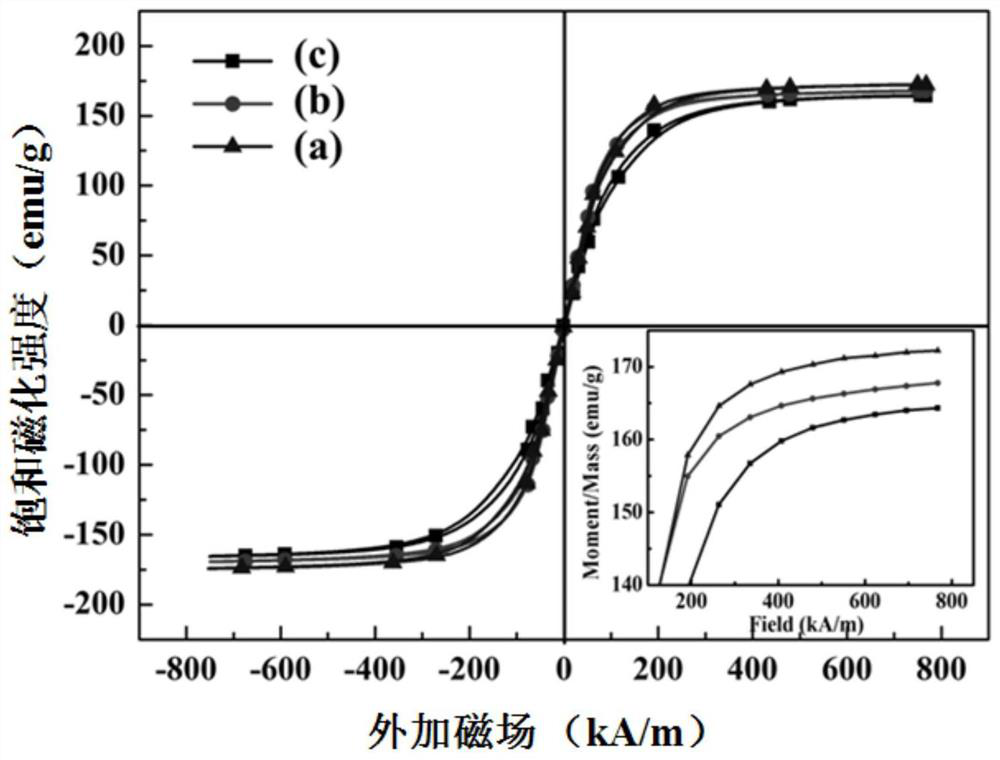

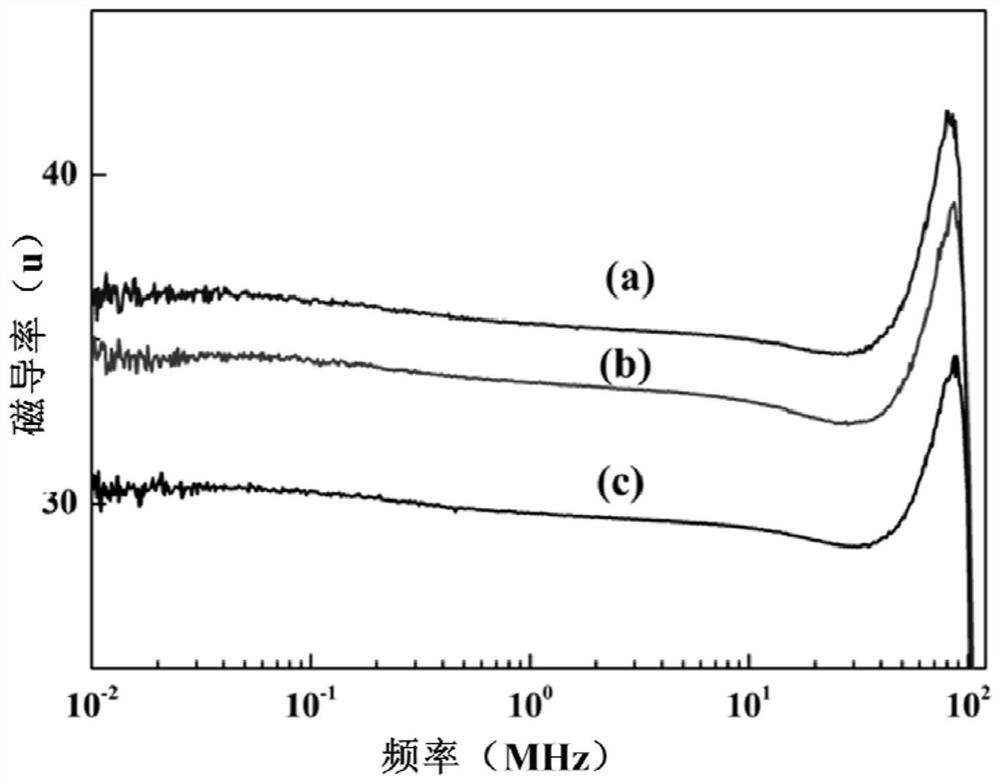

[0041] Fe prepared by the strip crushing method 77 Si 8.5 B 12 P 4 Nb 0.5 Amorphous alloy powder is subjected to magnetic field heat treatment for amorphous powder. Put the amorphous powder in a closed glass bottle, place the bottle in a magnetic field heat treatment furnace, first vacuumize the furnace body, and then heat the amorphous magnetic powder. Set the heat treatment temperature to 400°C. When the temperature rises When the set temperature is reached, apply a transverse magnetic field of 0.5T to the magnetic powder, and perform magnetic field heat treatment. After 30 minutes of heat treatment, turn off the magnetic field, turn off the heating system and the heat preservation system, and wait for the temperature to cool to room temperature, take out the magnetic powder, and use an X-ray diffractometer (XRD ) to detect its structure, the result is as figure 1 As shown in (a), it can be seen that there is no diffraction peak corresponding to any crystal in the XRD p...

Embodiment 2

[0046] Fe prepared by the strip crushing method 77 Si 8.5 B 12 P 4 Mo 0.5 Amorphous alloy powder is subjected to magnetic field heat treatment for amorphous powder. Put the amorphous powder in a closed glass bottle, place the bottle in a magnetic field heat treatment furnace, first vacuumize the furnace body, and then heat the amorphous magnetic powder. Set the heat treatment temperature to 420°C. When the temperature rises When the set temperature is reached, apply a transverse magnetic field of 0.6T to the magnetic powder, and conduct magnetic field heat treatment. After 30 minutes of heat treatment, turn off the magnetic field, turn off the heating system and the heat preservation system, wait until the temperature cools down to room temperature, take out the magnetic powder, and use XRD to detect its structure. XRD There is no diffraction peak corresponding to crystallization on the spectrum, only a broad diffuse scattering peak, indicating that the powder used is comp...

Embodiment 3

[0050] Fe prepared by the strip crushing method 77 Si 8.5 B 12 P 4 Ni 0.5 Amorphous alloy powder is subjected to magnetic field heat treatment for amorphous powder. Put the amorphous powder in a closed glass bottle, place the bottle in a magnetic field heat treatment furnace, first vacuumize the furnace body, and then heat the amorphous magnetic powder. Set the heat treatment temperature to 380°C. When the temperature rises When the set temperature is reached, apply a transverse magnetic field of 0.6T to the magnetic powder, and conduct magnetic field heat treatment. After 30 minutes of heat treatment, turn off the magnetic field, turn off the heating system and the heat preservation system, wait until the temperature cools down to room temperature, take out the magnetic powder, and use XRD to detect its structure. XRD There is no diffraction peak corresponding to crystallization on the spectrum, only a broad diffuse scattering peak, indicating that the powder used is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com