Method for preparing single crystal morphology nickel cobalt manganese lithium ion battery cathode material

A technology of nickel-cobalt-manganese-lithium and ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low single crystal degree of secondary particles and affect the electrochemical performance of positive electrode materials, and achieve high single crystal degree, The effect of reducing the loss of lithium source and better electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

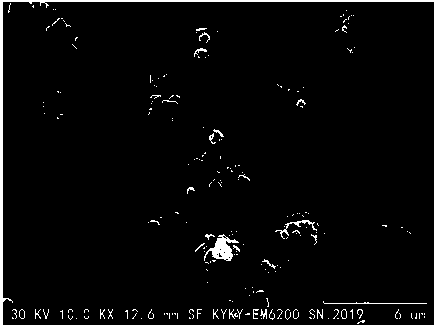

Image

Examples

example 1

[0026] 1. Synthesize the positive electrode material precursor by co-precipitation method, add 1 mol / l metal salt (nitrate) mixed solution, 3 mol / l sodium hydroxide solution, and 1 mol / l ammonia water into the reaction kettle dropwise, The ratio of nickel-cobalt-manganese elements in the solution is 5:2:3, the pH value of the control system is 9, water bath at 50°C for 12 hours, suction filtration, and vacuum drying at 120°C for 12 hours to obtain a precursor with a particle size distribution of D50=2-4um;

[0027] 2. Weigh 100g of the precursor in step 1, add boron oxide according to the mass percentage of the precursor at 0.2%, add molten salt sodium chloride at a mass ratio of 1:1, and mix evenly; keep warm at 500°C under the air atmosphere of the muffle furnace 2h. After primary sintering, the material is washed, filtered, vacuum-dried at 60°C, and passed through a 300-mesh sieve;

[0028] 3. According to the Li / M molar ratio of 1.10, mix the lithium carbonate with the po...

example 2

[0031] 1. Synthesize the positive electrode material precursor by co-precipitation method, add 1 mol / l metal salt (nitrate) mixed solution, 3 mol / l sodium hydroxide solution, and 1 mol / l ammonia water into the reaction kettle dropwise, The ratio of nickel-cobalt-manganese elements in the solution is 5:2:3, the pH value of the control system is 9, water bath at 50°C for 12 hours, suction filtration, and vacuum drying at 120°C for 12 hours to obtain a precursor with a particle size distribution of D50=2-4um;

[0032] 2. Weigh 100g of the precursor in step 1, add boron oxide according to the mass percentage of the precursor at 5.0%, add molten salt potassium chloride at a mass ratio of 5:1, and mix evenly; keep warm at 800°C in the air atmosphere of the muffle furnace 10h. After primary sintering, the material is washed, filtered, vacuum-dried at 60°C, and passed through a 300-mesh sieve;

[0033] 3. According to the Li / M molar ratio of 1.40, mix the lithium carbonate with the p...

example 3

[0036] 1. Synthesize the positive electrode material precursor by co-precipitation method, add 1 mol / l metal salt (nitrate) mixed solution, 3 mol / l sodium hydroxide solution, and 1 mol / l ammonia water into the reaction kettle dropwise, The ratio of nickel-cobalt-manganese elements in the solution is 5:2:3, the pH value of the control system is 9, water bath at 50°C for 12 hours, suction filtration, and vacuum drying at 120°C for 12 hours to obtain a precursor with a particle size distribution of D50=2-4um;

[0037] 2. Weigh 100g of the precursor in step 1, add boron oxide according to the mass percentage of the precursor at 2.5%, and add molten salt sodium chloride at a mass ratio of 2.5:1, and mix evenly; keep warm at 650°C in the air atmosphere of the muffle furnace 6h. After primary sintering, the material is washed, filtered, vacuum-dried at 60°C, and passed through a 300-mesh sieve;

[0038]3. According to the Li / M molar ratio of 1.25, mix the lithium carbonate with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com